Backwashing water processor

A water quality treatment machine and machine base technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of difficult promotion, clogging, and high cost of filter element use, so as to avoid service expenses, reduce use cost, and manage The effect of neat road arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

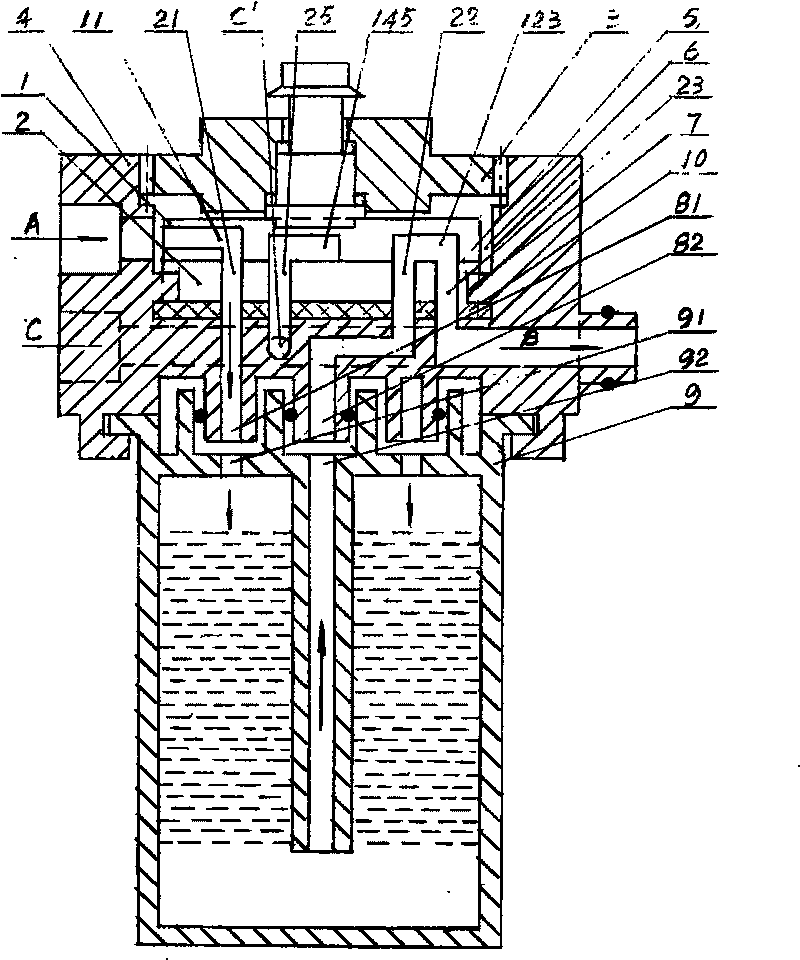

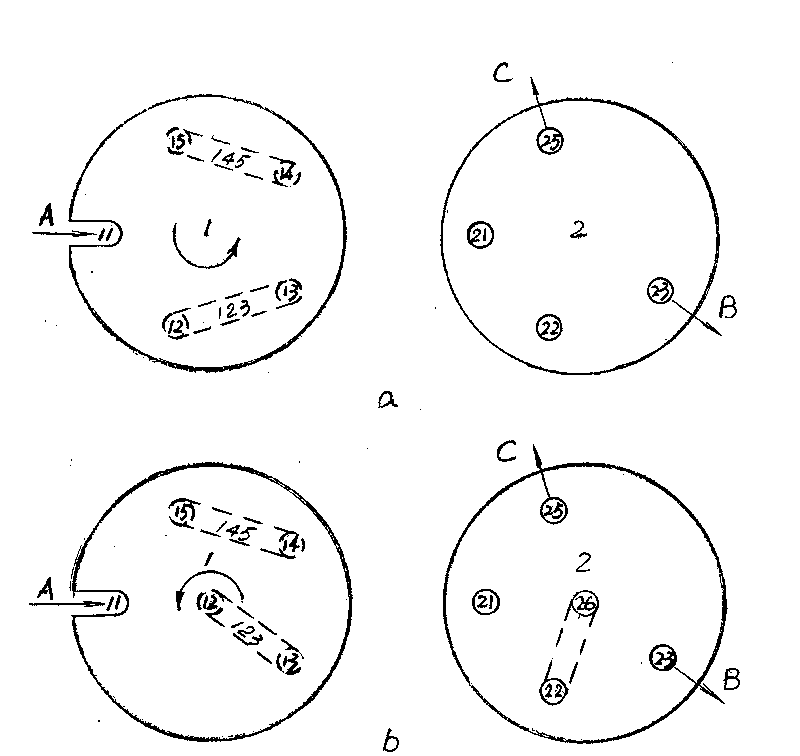

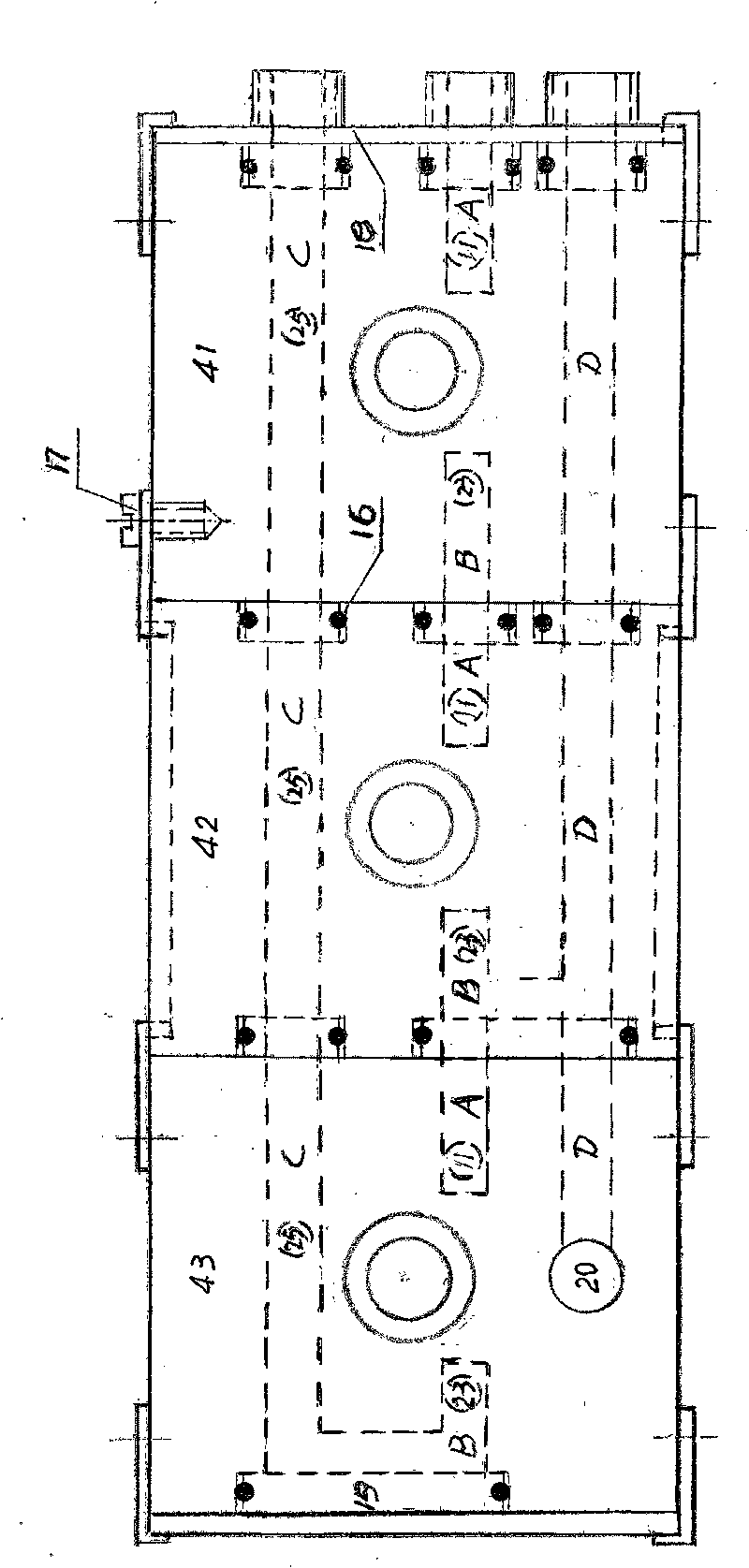

[0024] figure 1 It is the best embodiment of the present invention. There are upper and lower switching discs 1, 2 which have five equally divided switching positions and contact and cooperate with each other to form a sealed switching surface in the frame 4 with the inlet, outlet and discharge pipelines A, B, C and filter element 9. A waterway switcher 5 is formed; the waterway switcher 5 forms an inner cavity 6 communicating with the water inlet pipeline A with the sealing member 10, the leak-proof sealing member and the machine base 4. The water inlet 11 of the upper plate 1 with a gap in the waterway switcher 5 communicates with the inner cavity 6 . The stopper 7 places the lower wall 2 of the waterway switcher 5 on the upper limit of the machine base 4 . The water inlets 21, 22 of the bottom wall 2 communicate with the inlet and outlet 81, 82, 91, 92 of the machine base 4 and the filter element 9. The movable part 3 of the machine base 4 seals the waterway switcher 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com