Backward flow type tail gas treatment device

A tail gas treatment and tail gas technology, which is applied in the direction of using liquid separation agent, lighting and heating equipment, and separation of dispersed particles, can solve the problems of unclean emission and filtration, incomplete dust removal, filter clogging, etc., and achieve the effect of gas cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

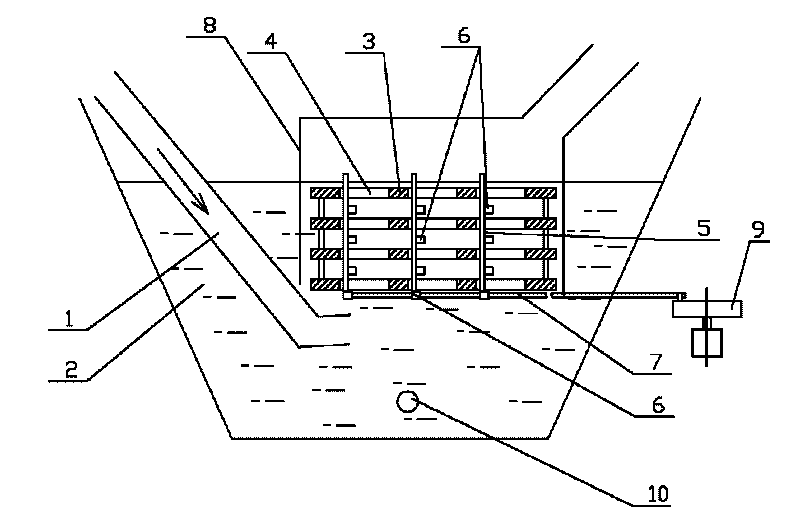

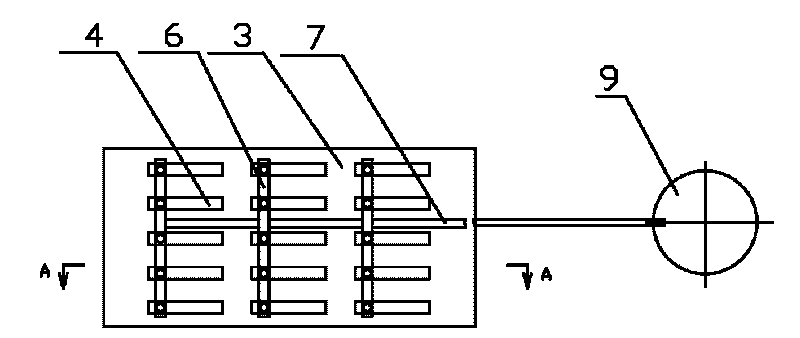

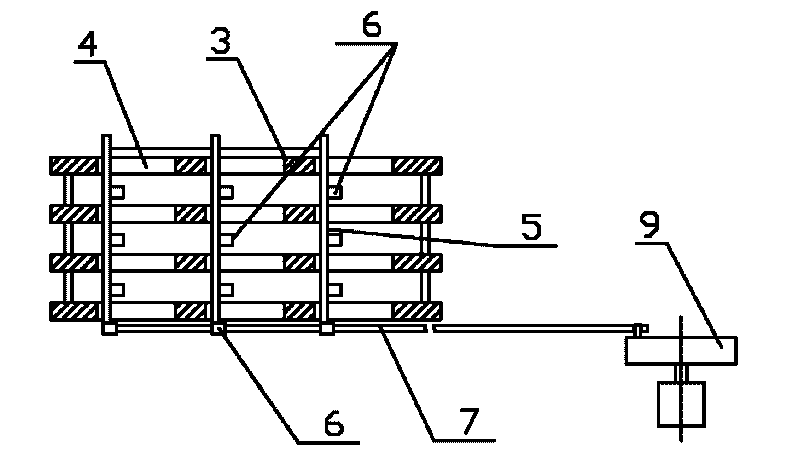

[0010] The backflow type tail gas treatment device of the present invention comprises a boiler tail gas outlet 1, and the boiler tail gas outlet 1 extends into the liquid tank 2, and the liquid surface of the liquid tank is provided with several layers of filter screens 3 with several rows of transverse through grooves 4, and each layer filters Interval settings between nets. By passing the tail gas discharged from boilers, industrial equipment and other equipment into the liquid, a large amount of dust, sulfide and other pollutants carried in the tail gas can be removed. When it gets bigger and bigger, when it passes through the bottom layer of the filter, the liquid bubbles continue to rise under the action of buoyancy, and must pass through the through groove of the filter, and the large liquid bubbles become small liquid bubbles after being hit and stirred, and then they can pass through Through the groove, after passing the through groove of the bottom filter net, the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com