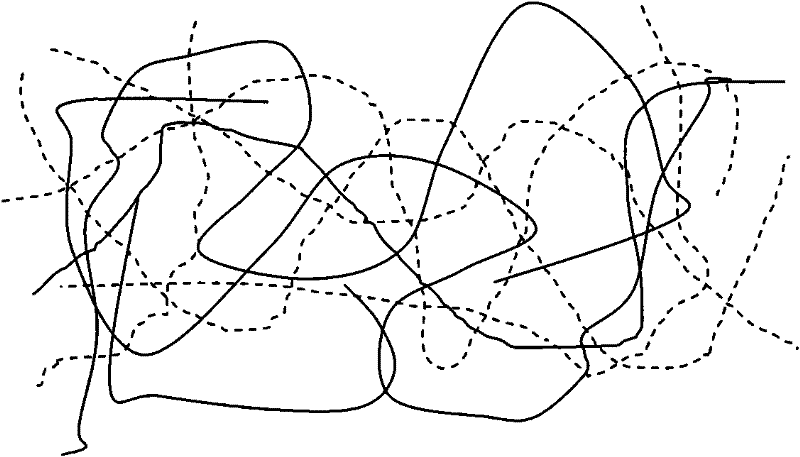

Perfluoro ion exchange membrane with interpenetrating network structure and preparation method thereof

An interpenetrating network structure, ion exchange membrane technology, applied in the field of polymer functional membrane materials, can solve the problems of difficult control of membrane material composite process, difficult mass production, environmental pollution of sulfonating agents, etc., to reduce membrane protons. The effect of exchange resistance, strong electrochemical corrosion resistance, and simple film production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

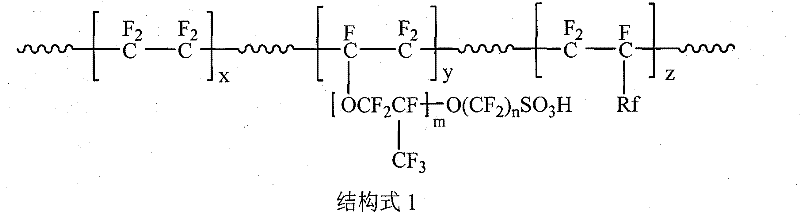

[0044] With 120g hydrogen type dry sulfonic acid resin (number average molecular weight 80,000, exchange capacity 0.95mmol / g, H + type) is dissolved in 880gN, in N-dimethylformamide (DMF), obtains sulfonic acid solution (casting solution), adds salt type perfluorosulfonic acid type ion exchange resin (structural formula 3, number average molecular weight 80,000, exchange Capacity 0.85mmol / g, Ce type) 50g, dissolve and stir evenly, drool on a smooth and horizontal glass surface, evaporate the solvent at 70°C for 10h to form a film, peel off the glass to obtain an ion exchange membrane, and treat with 5% hydrochloric acid An ion exchange membrane with an interpenetrating network structure with a film thickness of 50 microns was obtained.

Embodiment 2

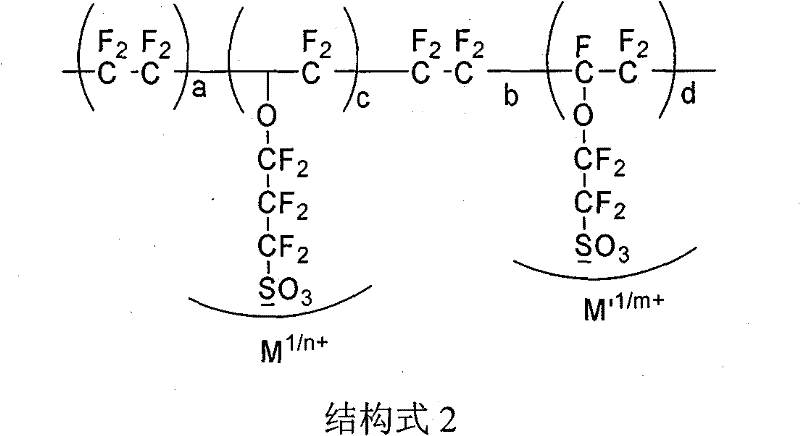

[0046] With 50g hydrogen type dry sulfonic acid resin (number average molecular weight 150,000, exchange capacity 0.8mmol / g, H + type) was dissolved in 880g dimethyl sulfoxide (DMSO) to obtain a sulfonic acid solution (casting solution), adding salt type perfluorosulfonic acid ion exchange resin (structural formula 2, number average molecular weight 80,000, exchange capacity 1.25mmol / g, La type) 50g, after dissolving and stirring evenly, drool on the surface of a smooth and horizontal Hastelloy flat plate, heat up to 150°C to evaporate the solvent for 1h to form a film, peel off the glass to obtain an ion exchange membrane, and use 12% hydrochloric acid An ion-exchange membrane with an interpenetrating network structure with a film thickness of 18 micrometers was obtained through treatment.

Embodiment 3

[0048] With 420g hydrogen type dry sulfonic acid resin (number average molecular weight 280,000, exchange capacity 1.05mmol / g, H + type) is dissolved in 880gN, in N-dimethylacetamide (DMAc), obtains sulfonic acid solution (casting solution), adds salt type perfluorosulfonic acid type ion exchange resin (structural formula 4, number average molecular weight 80,000, exchange Capacity 2.55mmol / g, Mn type) 100g, dissolve and stir evenly, drool on a smooth and horizontal glass surface, evaporate the solvent at 100°C for 2h to form a film, peel off the glass to obtain an ion exchange membrane, and treat with 10% sulfuric acid An ion exchange membrane with an interpenetrating network structure with a film thickness of 150 microns was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com