Special tool for restoring seat hole of machine of haven

A special tool, machine technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

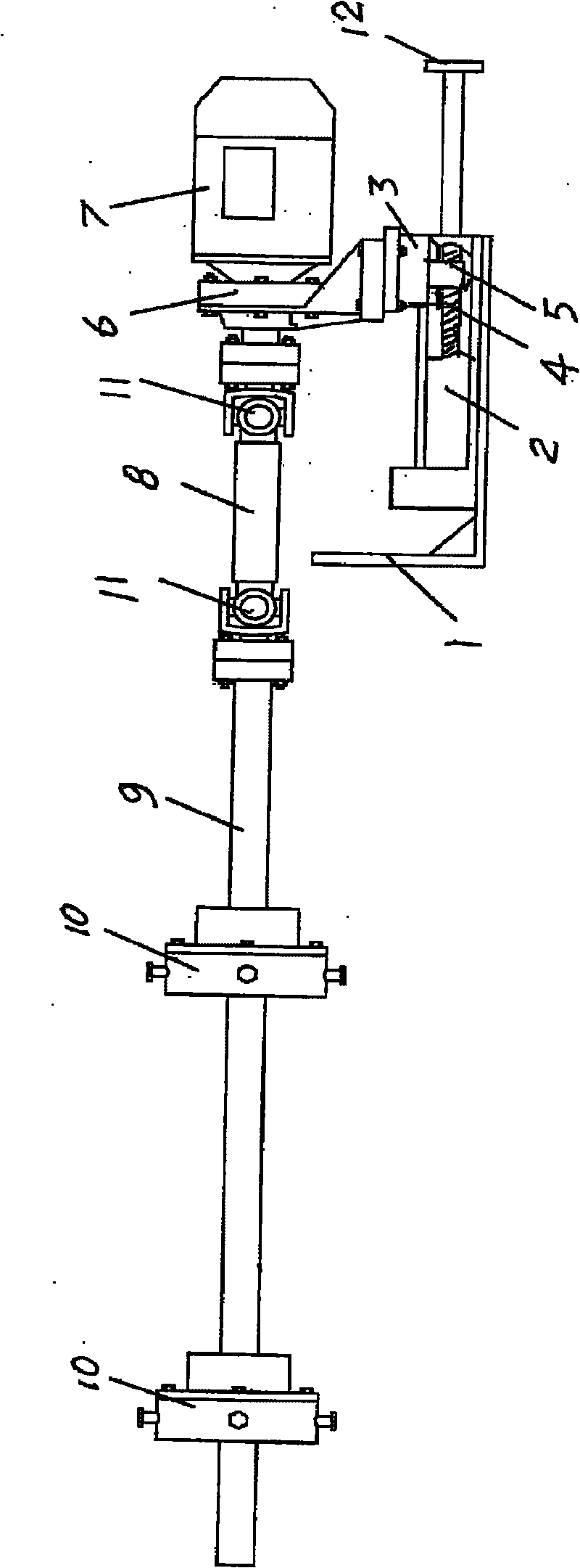

[0018] As shown in the figure, a special tool for repairing seat holes of port machinery has an angled base 1, and a U-shaped hole is arranged on the vertical angled plate of the angled base. A machine tool dovetail slideway seat 2 is installed on the corner base, a slide plate 3 with a dovetail groove is equipped on the dovetail slideway seat on the dovetail slideway seat, a rotatable lead screw 4 is installed on the dovetail slideway seat, and the lead screw and the slide plate The screw sleeve 5 at the bottom cooperates, and the motor 7 with the reducer 6 is installed above the slide plate. Two adjustment mounts 10.

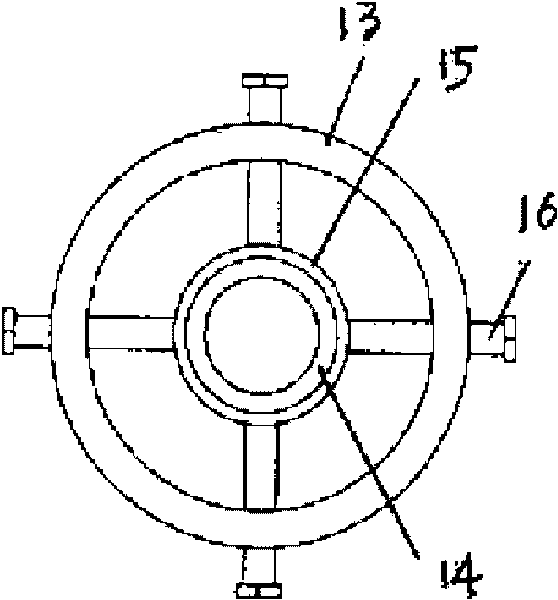

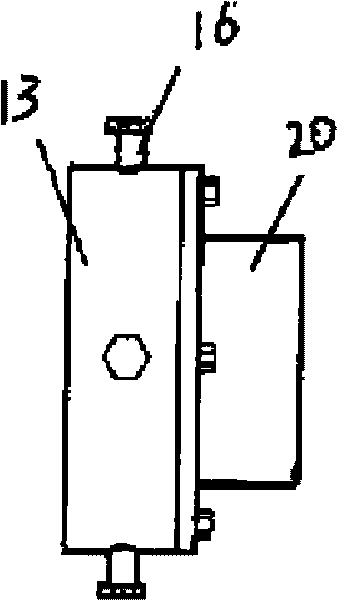

[0019] The adjustment frame has a flange plate 20, on which an annular outer cover 13 is housed, and the inner hole of the annular outer cover is inlaid with an axle sleeve 15 of an inner copper sleeve 14, and four screw holes are evenly distributed on the circumference of the annular outer cover, and the screw holes are arranged There are bolts 16, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com