Precise positioning and clamping device for stepped thin-wall barrel

A thin-walled cylinder and precise positioning technology, which is applied in positioning devices, auxiliary devices, clamping, etc., can solve the problem that there are no mature, effective and universal precise positioning and clamping tools for variable-diameter cylindrical thin-walled parts , to achieve the effect of uniform wall thickness difference, overcome deformation, and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

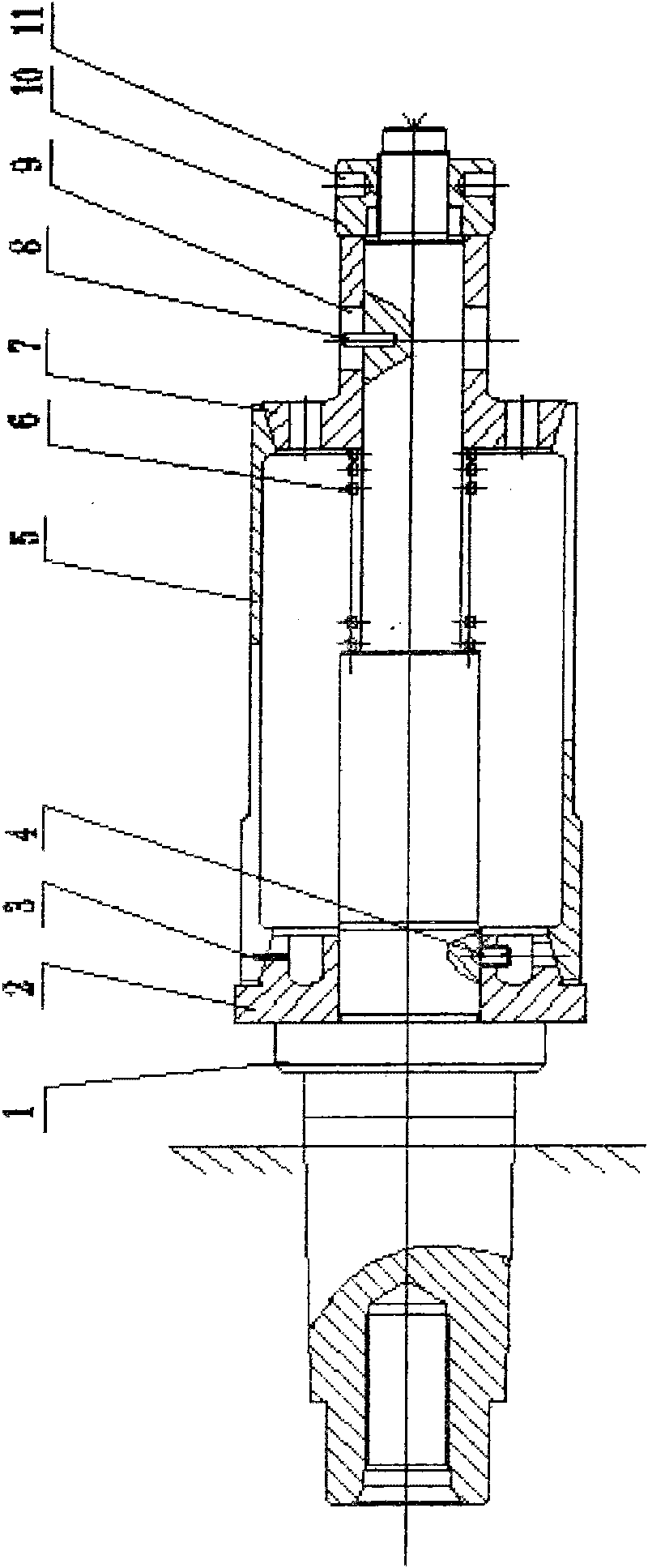

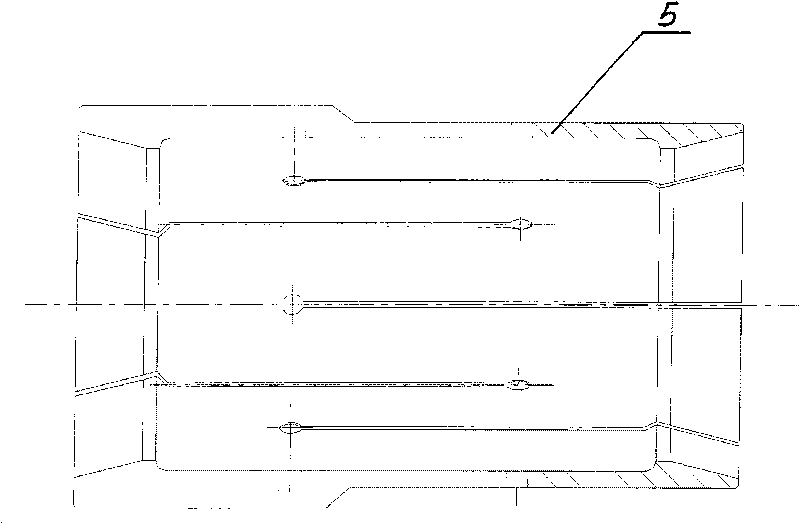

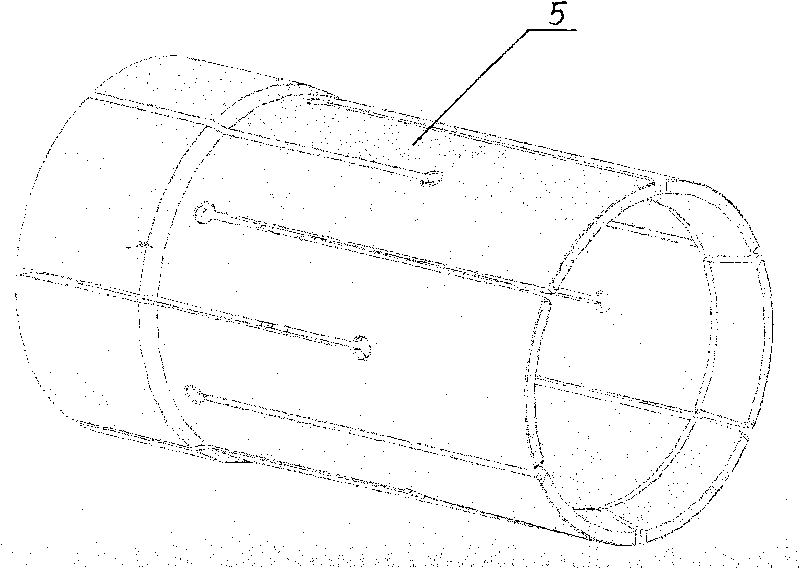

[0012] Such as figure 1 As shown, a step-type thin-wall cylinder precision positioning clamping device, which includes the main cone shaft 1, the fixed cone 2, the anti-rotation pin 3, the stop screw 4, the two-way step expansion spring 5, the spring 6, the movable cone Body 7, guide pin 8, waist-shaped hole 9, fastening nut 10, rotating handle 11.

[0013] The fixed cone 2 is mounted on the end surface of the first step of the main cone shaft 1 and fixed on the main cone shaft 1 by the stop screw 4, the spring 6 is mounted on the end surface of the second step of the main cone shaft 1, and the anti-rotation pin 3 is screwed into the pin hole on the fixed cone 2, the guide groove at the larger diameter end of the two-way step expansion spring 5 is aligned and inserted into the anti-rotation pin 3, and its left cone surface fits on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com