Apparatus and method for handling printing plates and printing plate exposure device

A technology of exposure device and lithographic plate, applied in printing plate, printing plate preparation, printing, etc., can solve the problem of strong distortion of lithographic plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

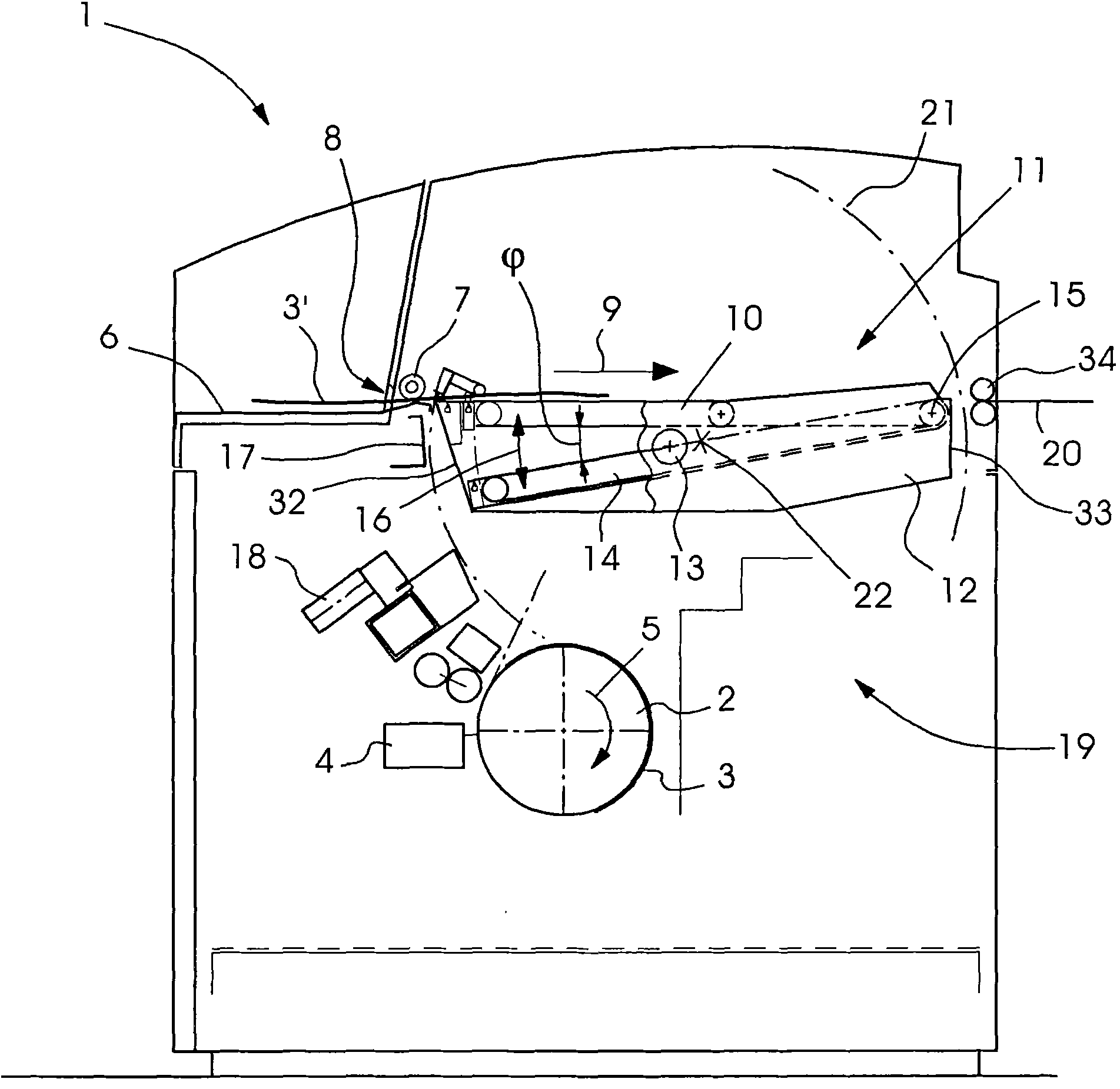

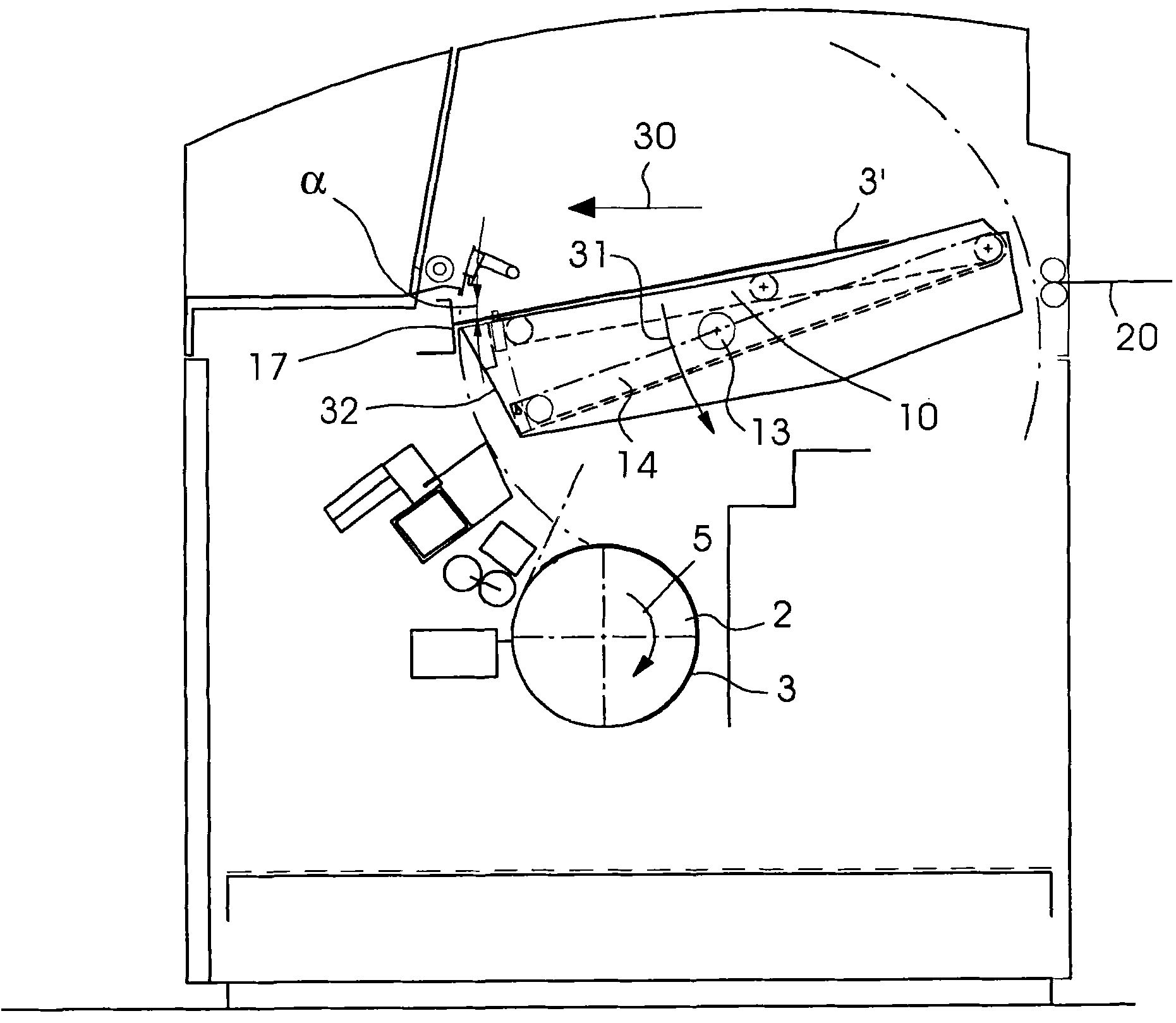

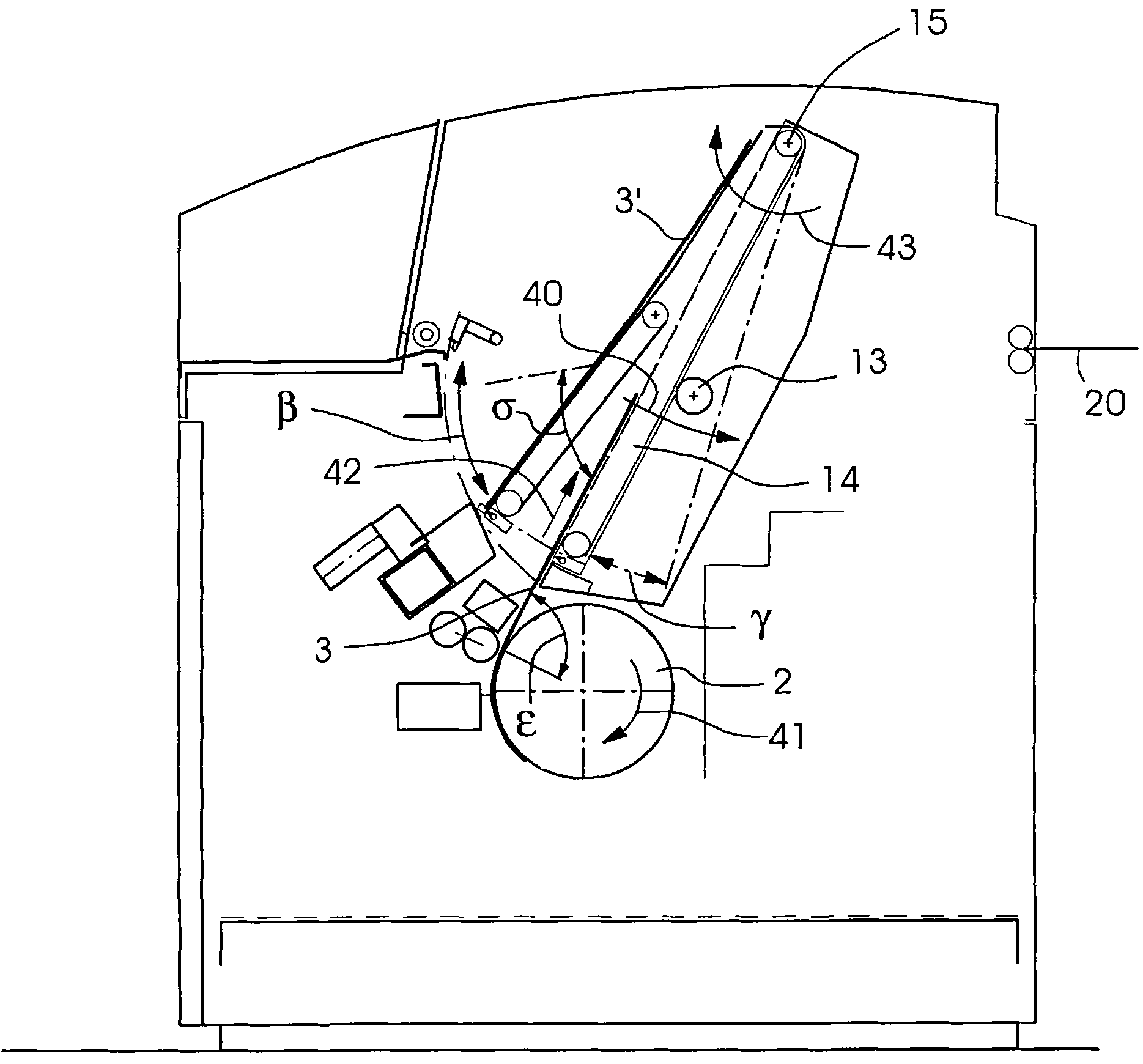

[0043] exist figure 1 A lithographic plate exposure apparatus 1 is shown in a cross-sectional view. The printing plate exposure device 1 is a semi-automatic device to which the printing plates 3 , 3 ′ are transferred manually via a printing plate transfer device 8 . For this purpose, the printing plate exposure device 1 has an input table 6 on the input side. For imaging the printing plates 3 , 3 ′, the printing plate exposure device 1 comprises an exposure cylinder 2 on which the printing plates 3 are clamped. To image the printing plate 3 , it is moved rotationally together with the cylinder 2 in the direction of the rotation arrow 5 and is imaged by an exposure mechanism 4 which can extend or move parallel to the axis of the exposure cylinder 2 .

[0044] In order to handle the supplied printing plate 3 ′ and the printing plate 3 clamped on the exposure cylinder 2 , the printing plate exposure device 1 has a printing plate receiving device 11 . The plate receiver 11 comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com