Ceramic material for sintering multi-layer ceramic capacitor at low temperature and preparation method thereof

A technology of multi-layer ceramics and ceramic materials, applied in the field of functional ceramic materials, can solve the problems of low dielectric constant, limit the miniaturization of MLCC components, and low specific volume ratio of MLCC, and achieve the effect of high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

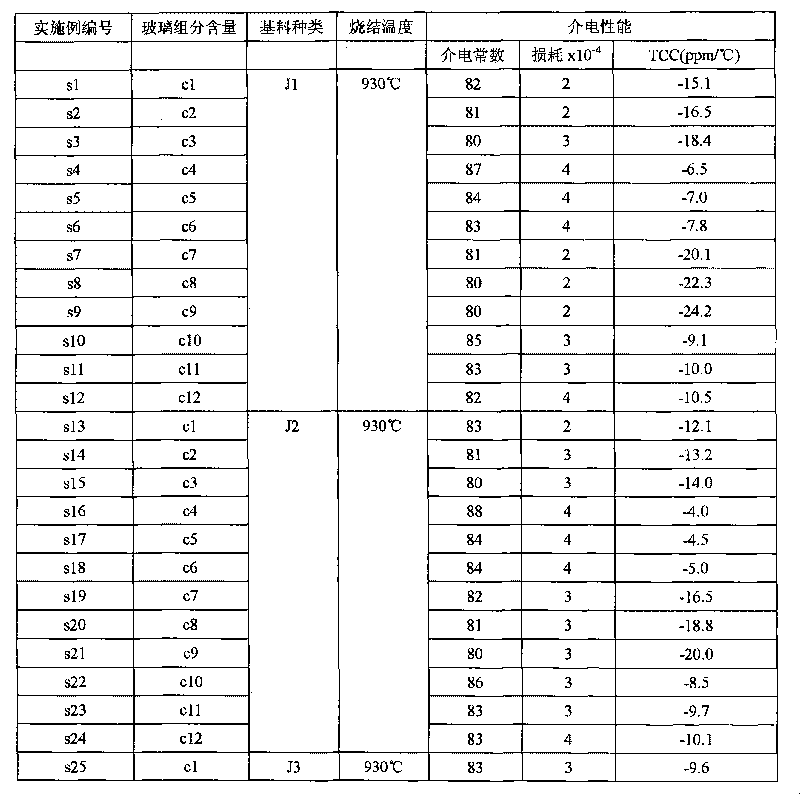

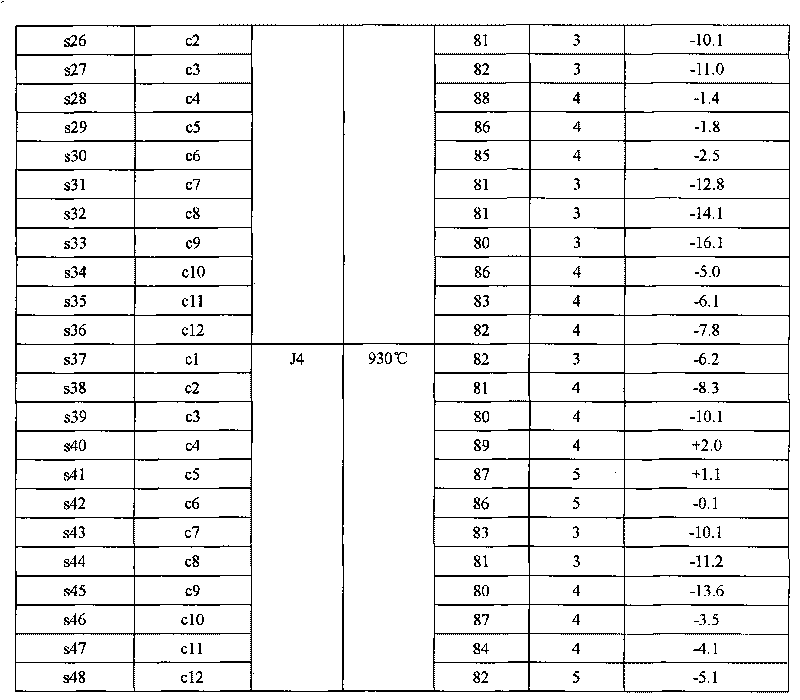

[0014] The ceramic powder of the present invention is composed of a main material with a weight percentage of 90 to 99 wt % and an auxiliary material with a weight percentage of 1 to 10 wt %:

[0015] 1) Main material: from aBaO-bLn 2 o 3 -cBi 2 o 3 -dTiO 2 The composition represented, wherein a, b, c and d independently represent the molar ratio, satisfy the following conditions: a+b+c+d=1, 0.13≤a≤0.17; 0.12≤b≤0.22; 0.01≤c ≤0.1; 0.4≤d≤0.74;

[0016] 2) Accessories: by eBi 2 o 3 -fB 2 o 3 -gZnO-hSiO 2 The glass represented by e, f, g and h independently represents the weight percentage, and satisfies the following conditions: e+f+g+h=100, 50≤e≤90; 5≤f≤30; 4≤g≤ 30; 1≤h≤20.

[0017] During the preparation of the present invention, the starting materials used to make the main material of the ceramic powder are not limited to the oxides of each element, and carbonates, nitrates, and organic metal salts of each constituent element can be used instead. Preferably, the pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com