Intelligent verticality adjusting method and device of ultra-deep topdown construction method stand column pile

A technology of upright pile and reverse method, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems that cannot be applied to ultra-deep upright pile, and achieve the effect of improving the adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

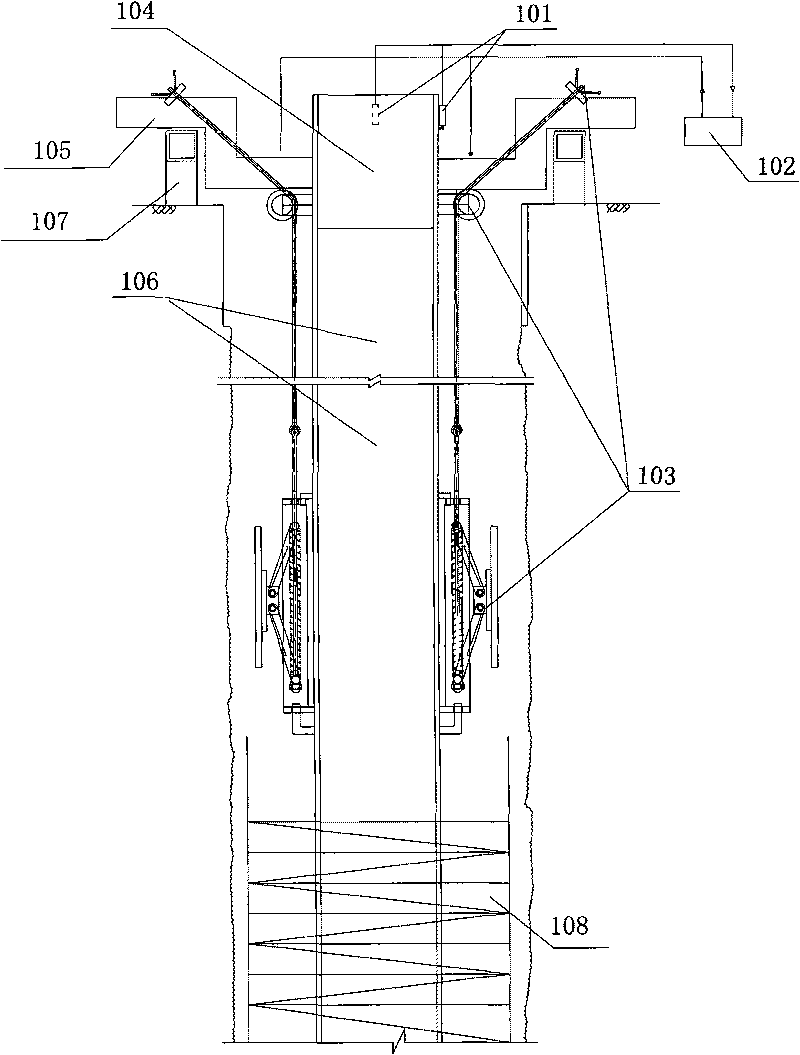

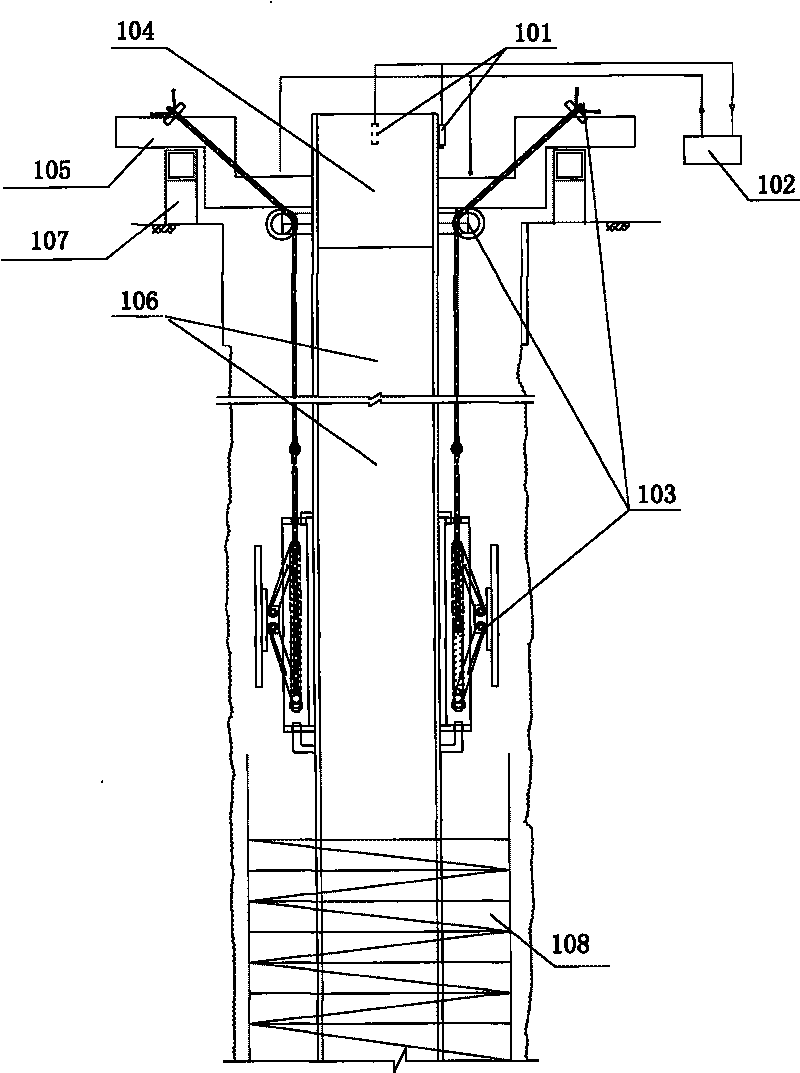

[0012] figure 1 Shown is the structural schematic diagram of the intelligent vertical adjustment device for ultra-deep upright piles proposed by the present invention. Such as figure 1 As shown, the embodiment of the intelligent vertical adjustment device for ultra-deep upside-down piles proposed by the present invention includes the following structures.

[0013] The detachable tool-type steel pipe 104 is used as an inclinometer to dock with the ultra-deep steel column 106 axis. The top fixing device fixes the detachable tool type steel pipe 104 on the ground at the designed position. In the embodiment of the present invention, the top fixing device is composed of a positioning sleeve 105 and a hydraulic support device 107 arranged under the positioning sleeve 105 to play a supporting role. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com