Hydraulic butterfly valve with automatic lubricating device

An automatic lubrication and butterfly valve technology, applied in the direction of valve device, valve operation/release device, valve lift, etc., can solve the problems of rotating shaft locking, switch failure, etc., and achieve the effect of ensuring safe production and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

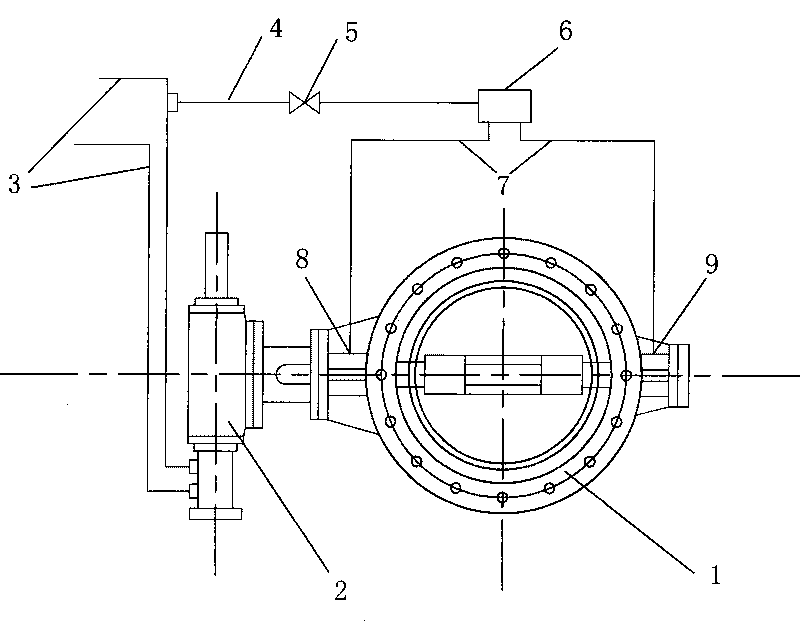

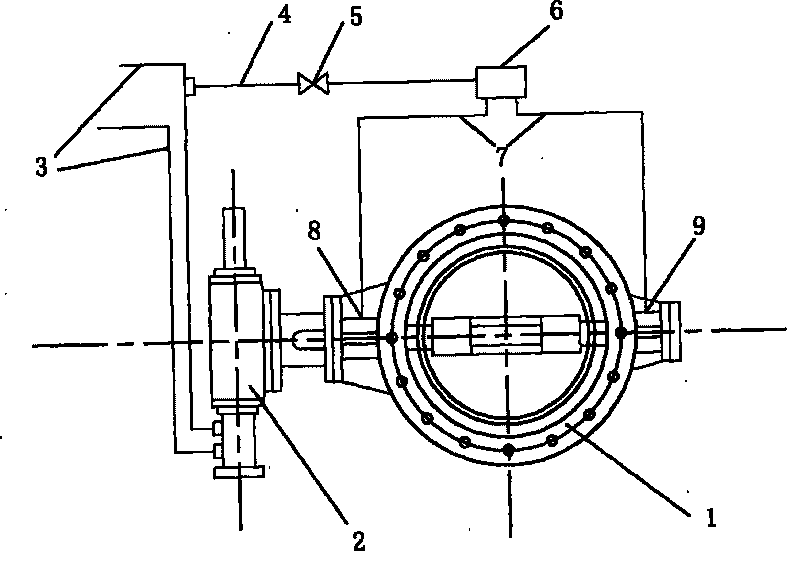

[0009] As shown in Figure 1, 1 is a common butterfly valve. It is usually composed of a valve housing, a rotating shaft and a butterfly plate fixed on the rotating shaft. Its seals are divided into elastic seals and metal seals. body, or attached to the periphery of the butterfly plate. The 2nd, hydraulic drive system, it comprises oil cylinder, piston, gear rod that is connected on the piston, the gear that is connected with butterfly valve rotating shaft, and the hydraulic oil pipe 3 that feeds oil to oil cylinder is made up of. The 4th, branch circuit oil pipe, its one end is connected hydraulic oil pipe 3, and one end is connected with oil distribution joint 6, and a valve 5 is installed in the middle, to control branch circuit oil supply oil supply or not. The 7th, pressure-measuring flexible pipe, altogether two, their one end connects the oil distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com