Long-shot optical-train type precision approach course indicator light structure

A technology of indicator light and light group, which is applied in the aviation field, can solve the problems of high processing precision, difficulty in realizing the requirement of 3-point angle, and difficult adjustment of optical path, etc., achieve large defocus tolerance, solve high processing precision requirements, reduce The effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

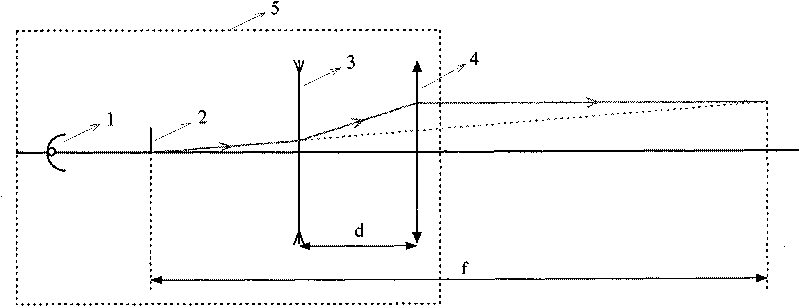

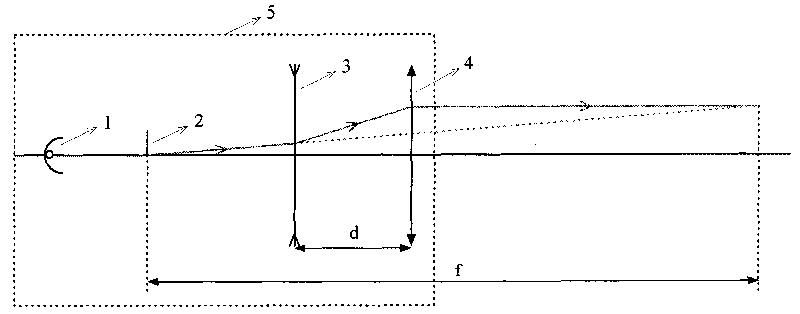

[0012] Embodiment 1: as figure 1 As shown, the indicator light structure includes a light source device 1, a color filter 2, a concave lens 3, a convex lens 4 and a light box 5; the inside of the light box 5 is sequentially installed with a light source device 1, a color filter 2, a concave lens 3 and a convex lens 4, and the filter The lower edge of the color film 2, the center of the concave lens 3 and the center of the convex lens 4 are on the same horizontal line; the focal length of the convex lens 4 is 312mm, the focal length of the concave lens 3 is -217.2mm, and the diameter of the two lenses is 130mm. The concave lens 3 and the convex lens The distance d between 4 is 156mm, so the focal length of the telephoto optical group composed of concave lens 3 and convex lens 4 is 1107.3mm, and the distance between color filter 2 and concave lens 3 is about 553.7mm.

[0013] The defocus tolerance of the system is 8.3mm, which is 13 times that of the single lens structure.

[0...

Embodiment 2

[0015] Embodiment 2: The light source device 1 has adopted a red or white LED light source, and the color filter 2 is a diaphragm, and the rest are the same as in Embodiment 1. Two sets of the system (red light and white light) form a complete precision process Approach light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com