Wafer tester and testing method thereof

A wafer testing and wafer technology, which is applied in the wafer testing apparatus and its testing field, can solve the problems of microcircuit damage, inability to provide the amount of pressure under the probe card, and probe failure damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

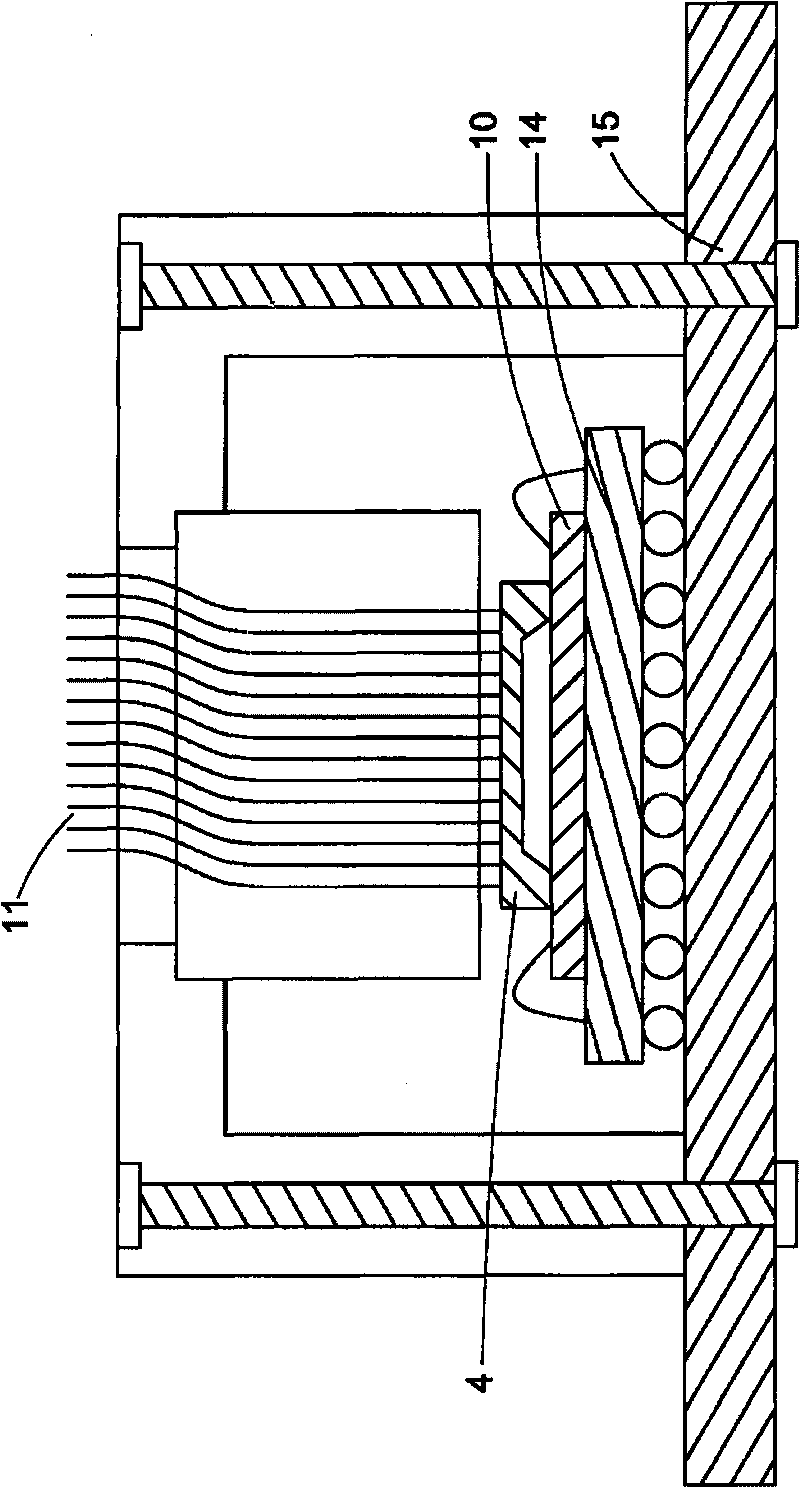

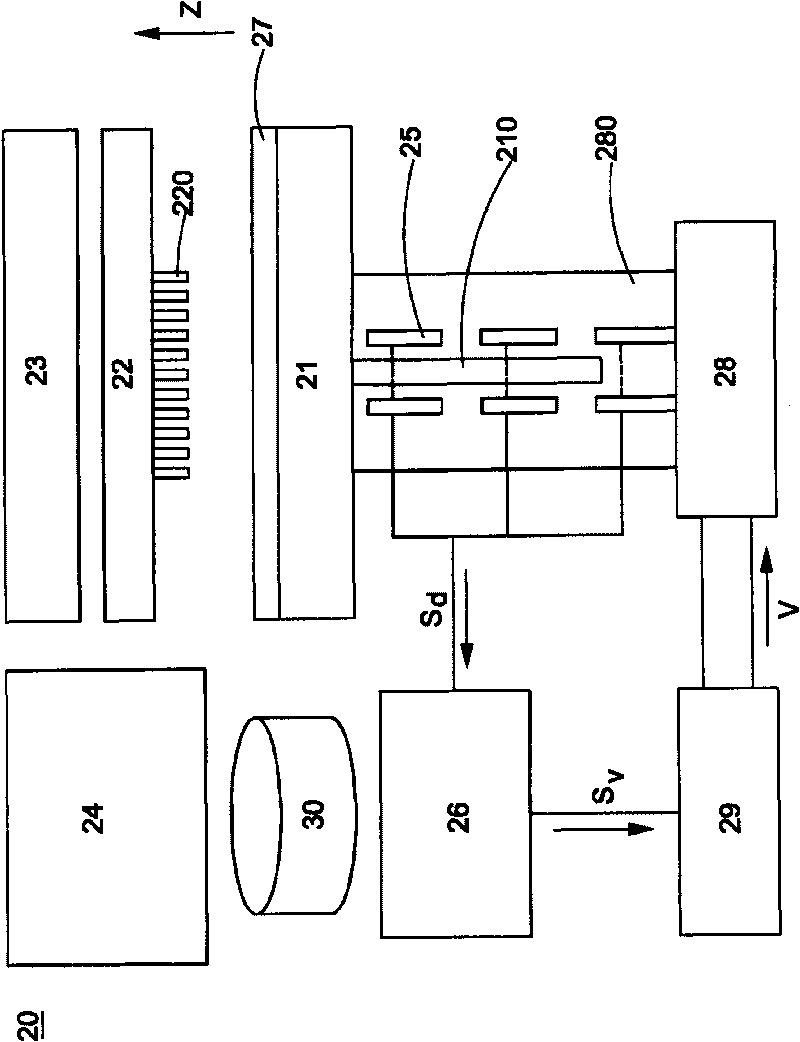

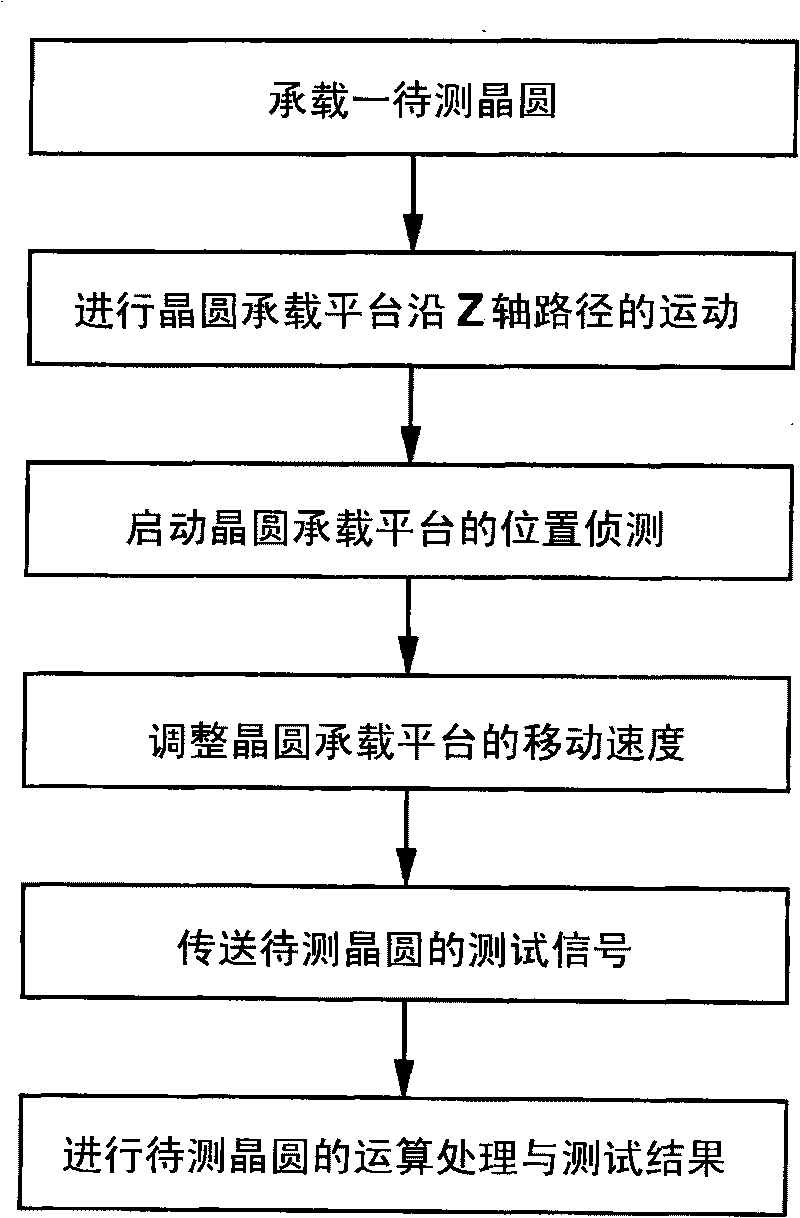

[0018] Please refer to figure 2 , is the first preferred embodiment proposed by the present invention, and is a schematic diagram of a wafer testing device. This wafer testing device 20 includes a wafer carrying platform 21, a probe card 22, a test carrier board 23, a test bench 24, a plurality of converters 25, and a feedback device 26, wherein the wafer carrying platform 21 is used To carry a wafer 27 to be tested, and this wafer carrying platform 21 is connected with a base 28 by a transmission mechanism 280, and the base is further connected with a driving motor 29, thus driving the motor 29 to provide wafer carrying The movement of the platform 21 in the X-Y-Z three-axis direction. The probe card 22 includes a plurality of probes 220 for detecting the wafer 27 to be tested on the wafer carrying platform 21 . The test carrier board 23 is a printed circuit board, one end of which is connected to the probe card 22 and the other end is connected to the test bench 24, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com