Magnetic image sensor

A technology of image sensor and sensor, applied in the field of magnetic image sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

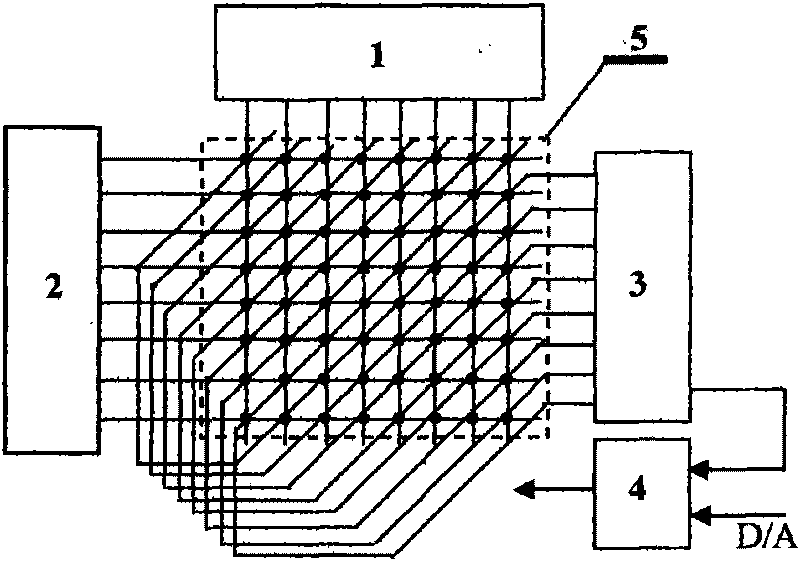

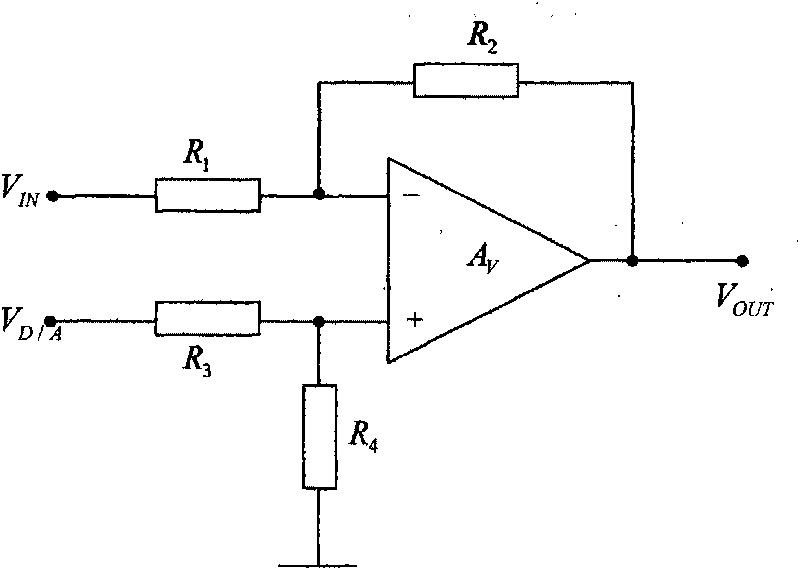

[0010] Now make a magnetic image sensor, its structure is as attached figure 1 As shown in the figure, (1) is an eight-to-one multi-way switch for column power supply, (2) is an eight-to-one multi-way switch for row power supply, (3) is an eight-to-one multi-way switch for output, and all three multi-way switches are selected DG408 Eight select one bi-directional multi-way switch. (4) For the zero-point correction and amplification circuit, select the OP07 low-drift linear amplifier and connect it into a differential circuit. (5) It is an 8×8 magnetic pixel matrix composed of 64 SS495A1 linear sensors. The selection control terminals of the three multi-way switches are controlled by the digital signal output by the computer data acquisition card, and the correction signal is controlled by the D / A of the data acquisition card. converter output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com