Ultrathin flexible liquid crystal display and manufacturing method thereof

A flexible liquid crystal and display technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of poor shock resistance, inability to bend, fragile glass, etc., and achieve the effect of good shock resistance and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments, but it should be noted that the embodiments of the present invention are only used to illustrate the technical solutions of the present invention, and not to limit the present invention.

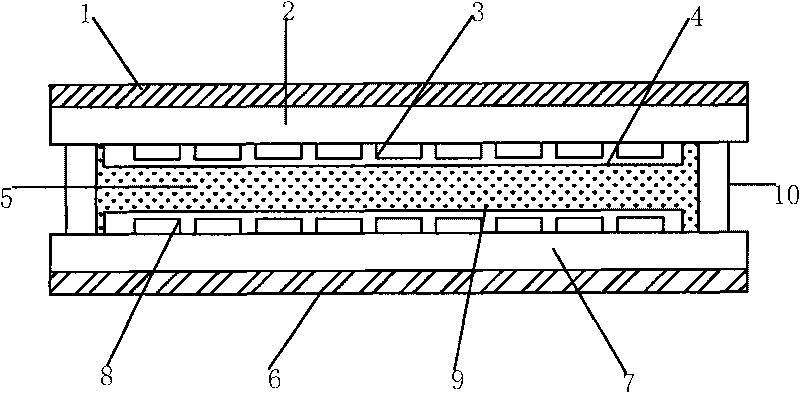

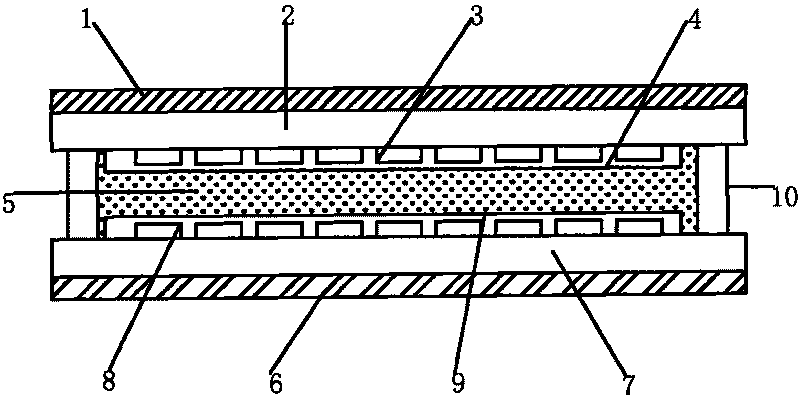

[0029] First, refer to figure 1 The specific structure of the ultra-thin flexible liquid crystal display (LCD) according to the present invention will be described.

[0030] like figure 1 As shown, the ultra-thin flexible LCD according to the present invention mainly includes the first polarizer 1, the first substrate (the first PET conductive film) 2, the first electrode 3, the alignment layer 4, the liquid crystal layer 5, the second polarizer 6, the first 2 Substrate (second PET conductive film) 7, second electrode 8, alignment layer 9, sealing edge 10, etc. The layers of the LCD are arranged in order as shown in the figure, wherein the liquid crystal layer is sandwiched between two su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com