Manufacturing method of ITO film for touch screen

A film manufacturing method and touch screen technology, which are applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of scratches, low yield, and poor appearance of ITO films, and avoid the occurrence of resistance values. The effect of changing, improving yield, and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the embodiment of the present invention, the method for manufacturing an ITO thin film used for a touch screen, after the etching treatment, an etching protection layer is provided on the ITO thin film to protect the ITO thin film, which can provide a higher degree of cleanliness when the ITO thin film is cleaned, and at the same time Scratching and oxidation of the ITO film can be avoided, thereby improving the yield of the touch screen.

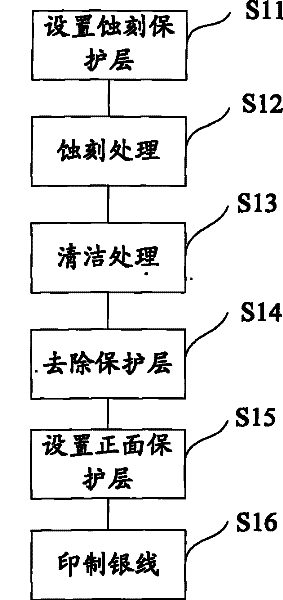

[0023] Such as figure 1 Shown, the present invention is used for the ITO film manufacturing method of touch screen, and this method comprises the following steps.

[0024] Step S11, setting an etching protection layer on the front of the ITO thin film, the etching protection layer protects the ITO layer on the ITO thin film, and removes the ITO layer not protected by the etching protection layer.

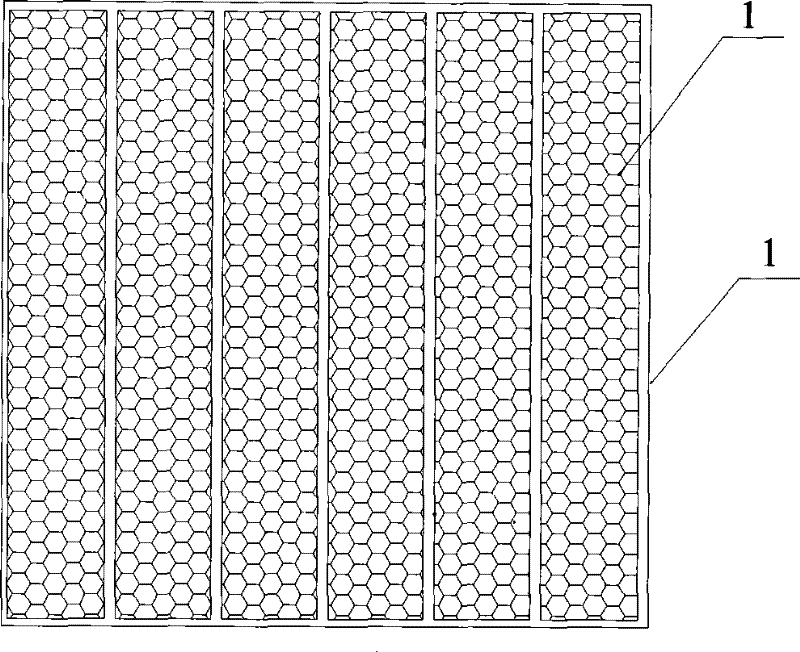

[0025] In the manufacture of ITO films for touch screens, etching is basically carried out on larger-area ITO films according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com