Method for repairing circuits of embedded circuit board

A circuit board and circuit technology, used in printed circuit components, secondary processing of printed circuits, metal pattern materials, etc., can solve problems such as open circuit, circuit short circuit, and waste of embedded circuit board production costs, so as to reduce waste, Avoid the effect of overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

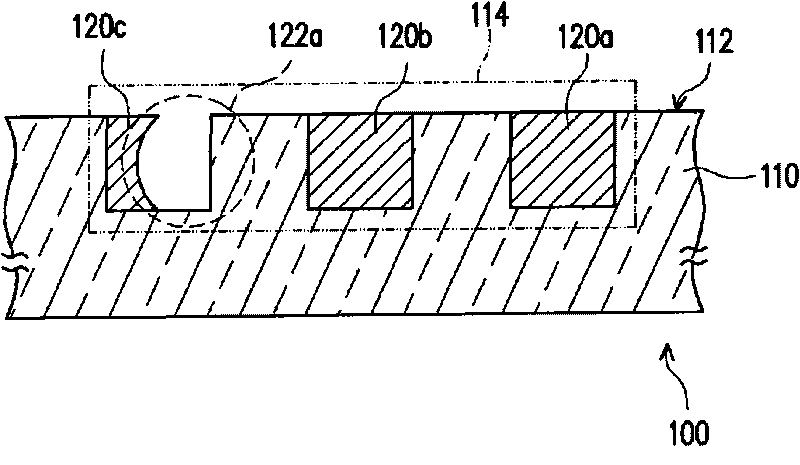

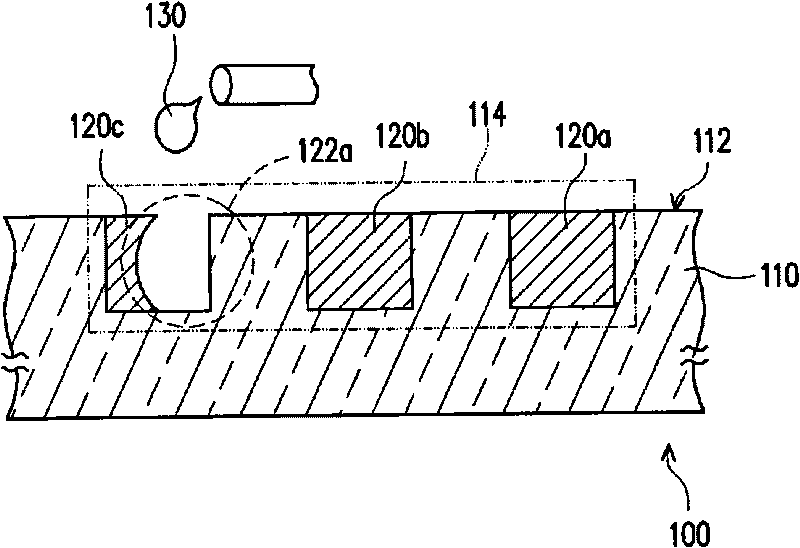

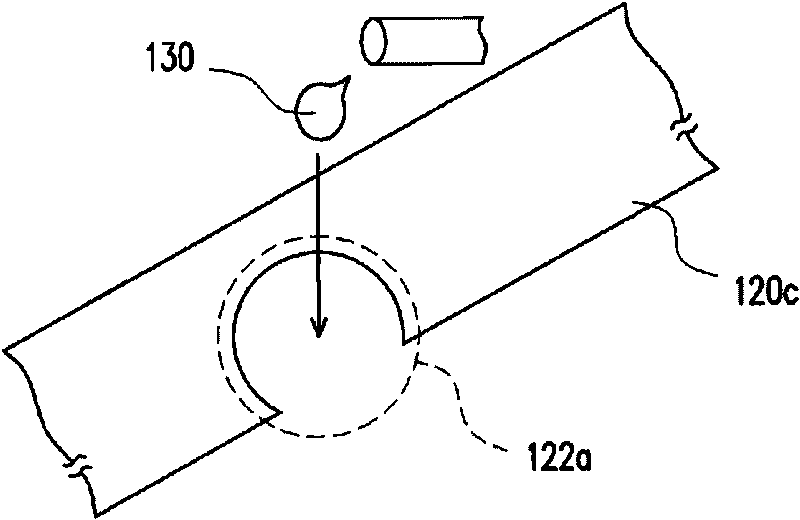

[0038] Figure 1A to Figure 1B It is a schematic cross-sectional view of a method for repairing lines of an embedded circuit board according to an embodiment of the present invention, Figure 1C for repair Figure 1B The top view enlarged schematic diagram of the local circuit of the embedded circuit board. Please refer to Figure 1A According to the method for repairing the circuit of an embedded circuit board in this embodiment, firstly, an embedded circuit board 100 is provided. The embedded circuit board 100 includes a dielectric layer 110 and a plurality of circuits 120a-120c ( Figure 1A Only three are schematically shown in ), wherein the dielectric layer 110 has a surface 112 and an indented pattern 114, the lines 120a-120c are located in the indented pattern 114 of the dielectric layer 110, and the line 120c has a defect 122a.

[0039] It is worth mentioning that the structure of the embedded circuit board 100 may only have a single circuit layer, or may have multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com