Method for twisting twisted frame type agitating blade and die thereof

A frame type stirring and stirring paddle technology, which is applied to a twisting method and a mold of a twist frame type stirring paddle, belongs to the field of stirring devices, can solve the problem of low manufacturing precision, and achieves the effects of ensuring precision, easy manufacturing and standard paddle shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

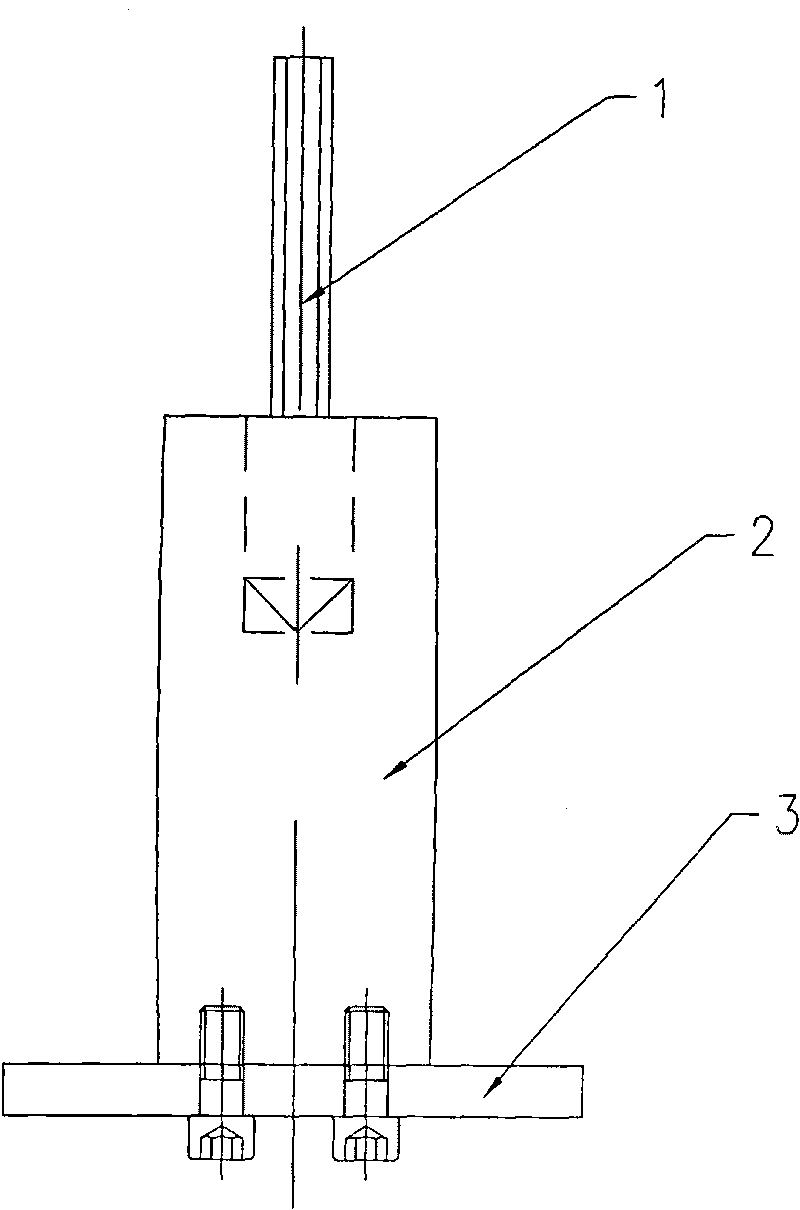

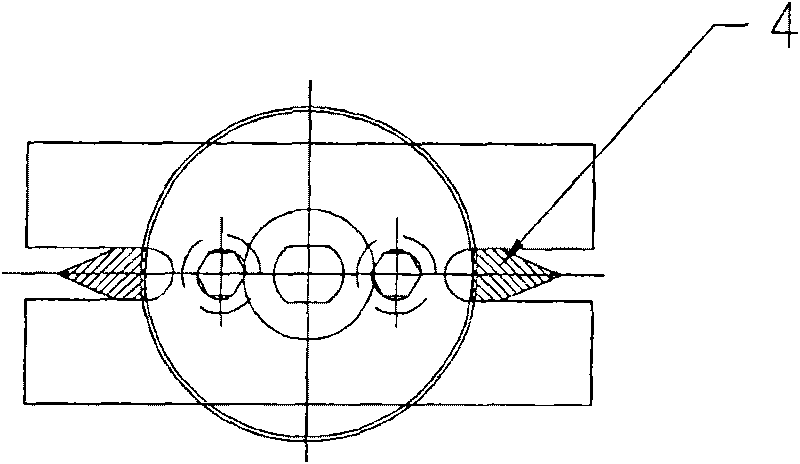

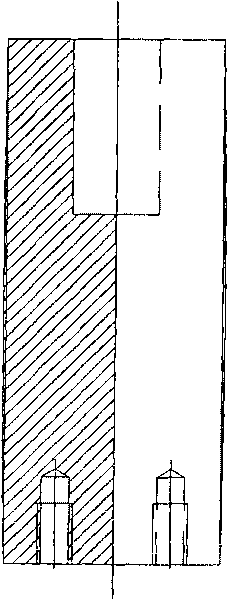

[0018] In the figure: guide shaft 1, mold body 2, splint 3, stirring paddle 4.

[0019] as attached figure 1 , attached figure 2 Shown, the present invention is made up of guide shaft 1, mold body 2, splint 3, has mounting hole on the mold body upper end, and mold body is drum-shaped cylinder, and guide shaft is installed on the mold body upper end, and guide shaft can be in the mold body Rotate freely, install a splint at the lower end of the mold body, the splint is fixed on the mold body, and there is a groove at both ends of the splint. When in use, the two vertical sides of the paddle 4 blank are respectively stuck in the grooves at both ends of the splint, and the hole on the paddle head is also passed through by the guide shaft at the same time. Clamp the paddle head with a wrench and twist the wrench until The two vertical sides of the stirring paddle become hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com