Device for manufacturing aluminum alloy plate for lithographic printing plate

An aluminum alloy plate and aluminum alloy technology, applied in the manufacture of aluminum alloy plates for lithographic printing plates, and in the field of manufacturing devices for aluminum alloy plates for lithographic printing plates, can solve problems such as continuous casting plate failures, and achieve the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the present invention will be described with reference to the drawings.

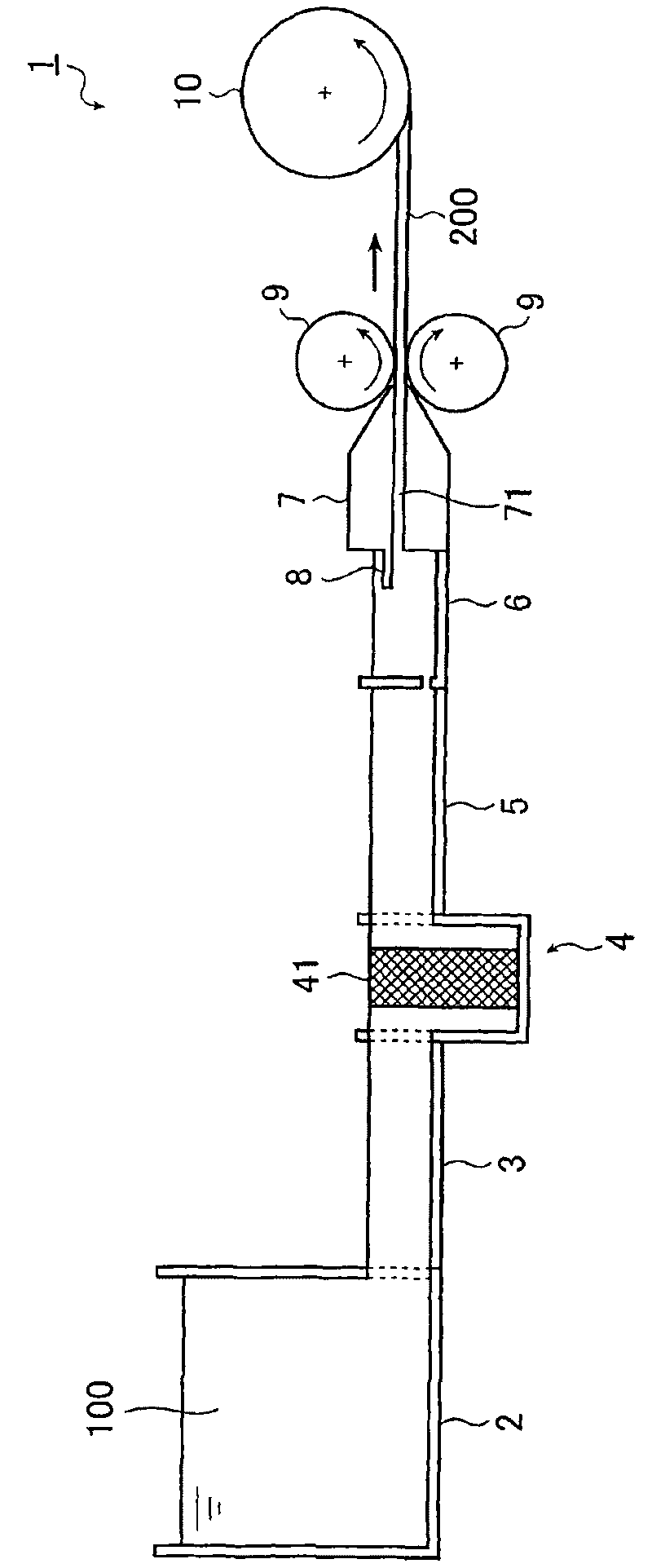

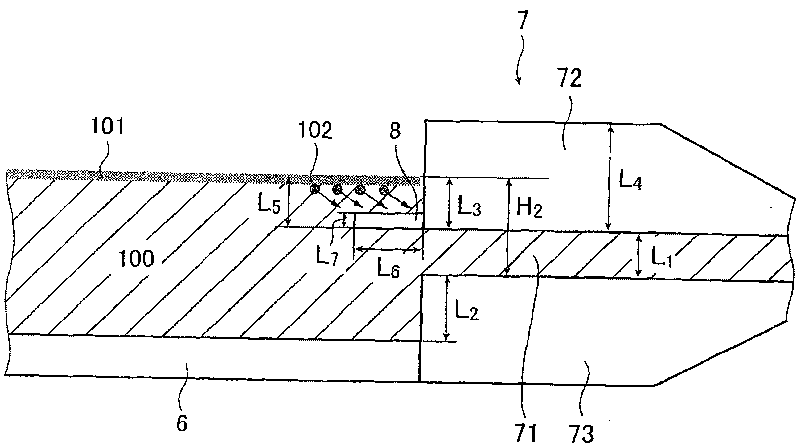

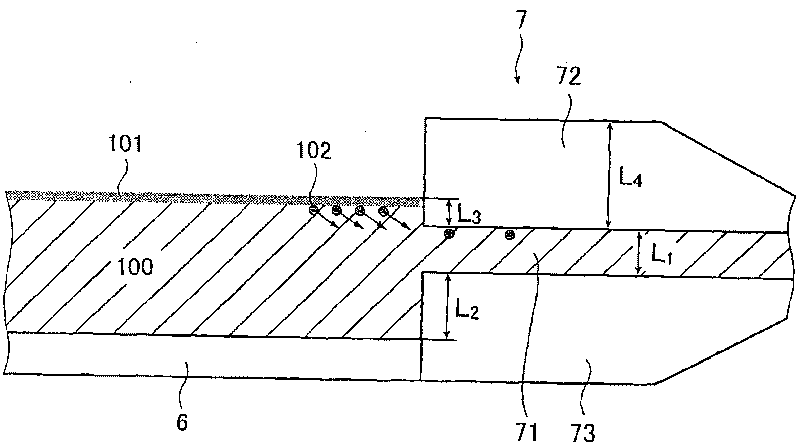

[0040] figure 1 It is a front view showing one embodiment of the continuous casting rolling apparatus used in the manufacturing method of the aluminum alloy plate for lithographic printing plates of this invention. exist figure 1 In , the wall surface on the front side of the figure is omitted. Furthermore, this also applies to all front views of the application.

[0041] exist figure 1 In the shown continuous casting and rolling apparatus 1, aluminum alloy molten metal (hereinafter referred to as "Al molten metal") that is adjusted to a desired composition by melting raw aluminum and adding Fe, Si, etc. is stored in a melting and holding furnace 2. ”)100. As a method of adding Fe, Si, etc., methods such as adding a master alloy of Al—Fe (25 wt %) and a master alloy of Al—Si (25 wt %) are mentioned, for example. A preferable composition of the Al molten metal will be described l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com