Device for correcting precision of rack installation surface of lathe body of lathe

A lathe bed and mounting surface technology, which is applied in the field of large and heavy CNC lathes, can solve the problems of excessive precision, bed deformation, and insufficiency, and achieve the effects of easy guarantee of position tolerance, high processing efficiency, and reduced labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

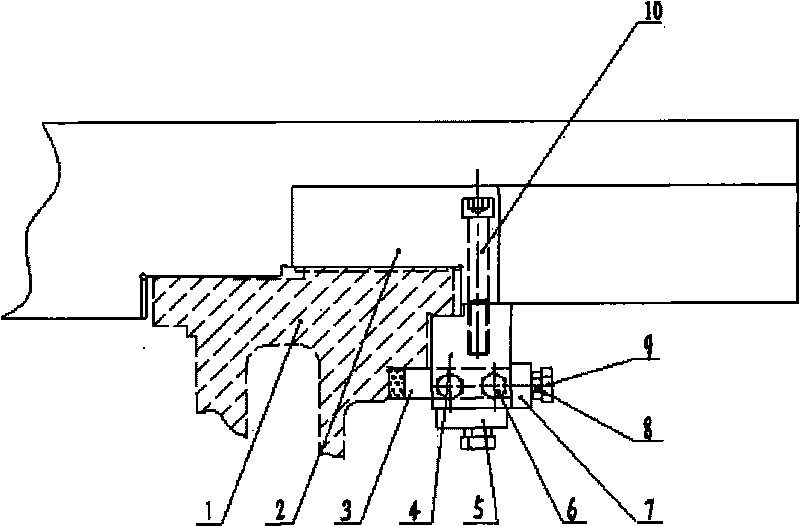

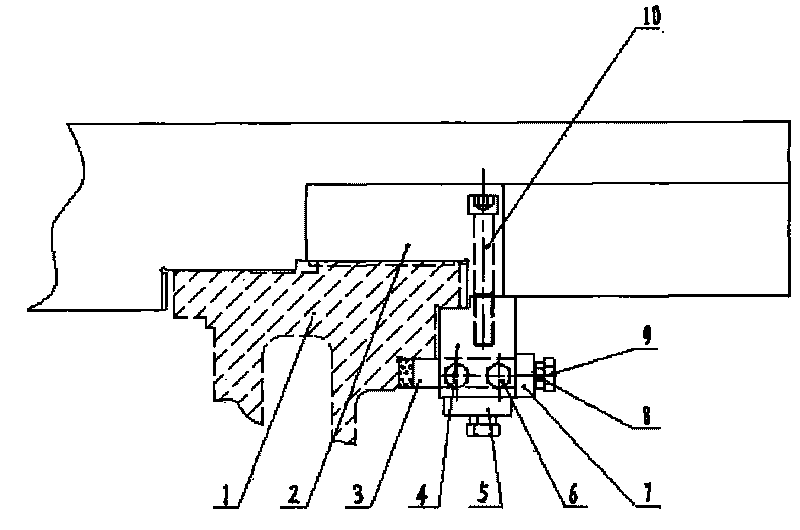

[0016] Such as figure 1 As shown, the present invention includes a tool holder 4 arranged on the saddle 2 of the lathe, and is characterized in that: a tool 3 is installed in the tool holder 4, and the tool 3 is a wide-edged planer, and the tool holder 4 moves with the electric tailstock of the lathe Do synchronous movement to realize the correction of the rack mounting surface of the lathe bed 1.

[0017] The tool holder 4 is connected with the lathe saddle by screws 10 through the mounting hole of the pressure plate of the lathe saddle 2 . The cutter 3 (wide-edged planer 3) that is positioned in the tool holder 4 is fixed in the tool holder 4 by two compression bolts 6 that are arranged on the side of the tool holder.

[0018] At the rear of the tool holder 4, a front and rear adjustment plate 7 is provided, and an adjustment bolt 9 is threaded on the front and rear adjustment plate 7. Tightening lock nuts 8 are installed between the adjustment plates 7 , and the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com