Torque-control multishaft bolt tightening machine

A technology for torque control and shaft bolts, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as affecting the accuracy and quality of workpieces, increasing the workload of workers, difficult management and control, etc., to improve work efficiency, Conducive to automatic control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

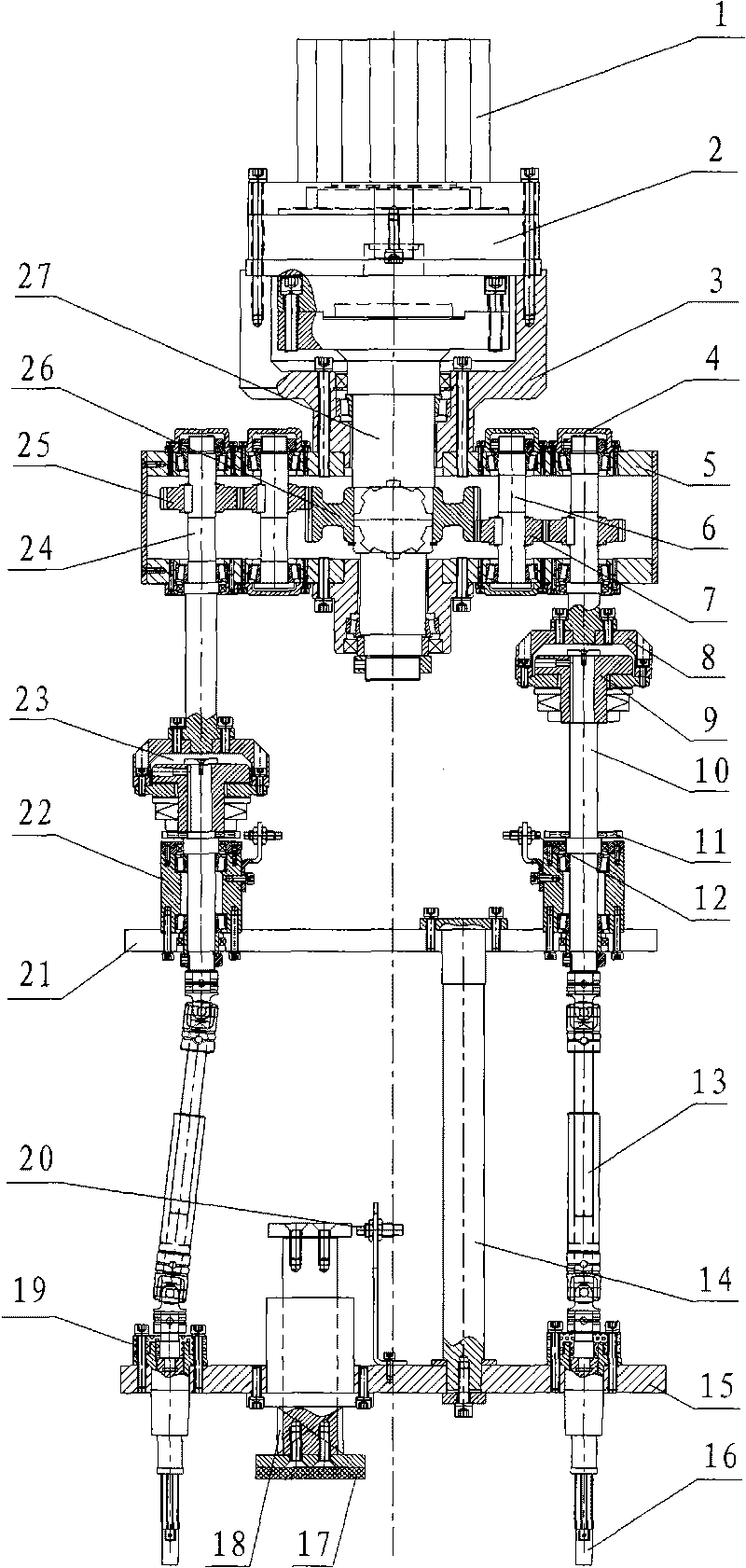

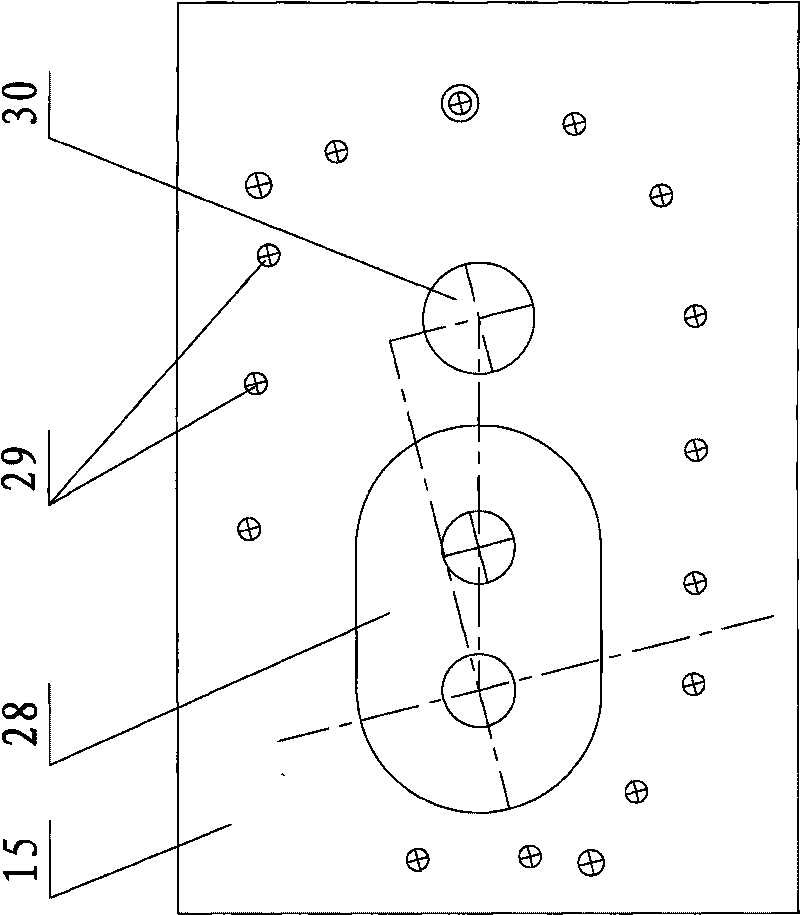

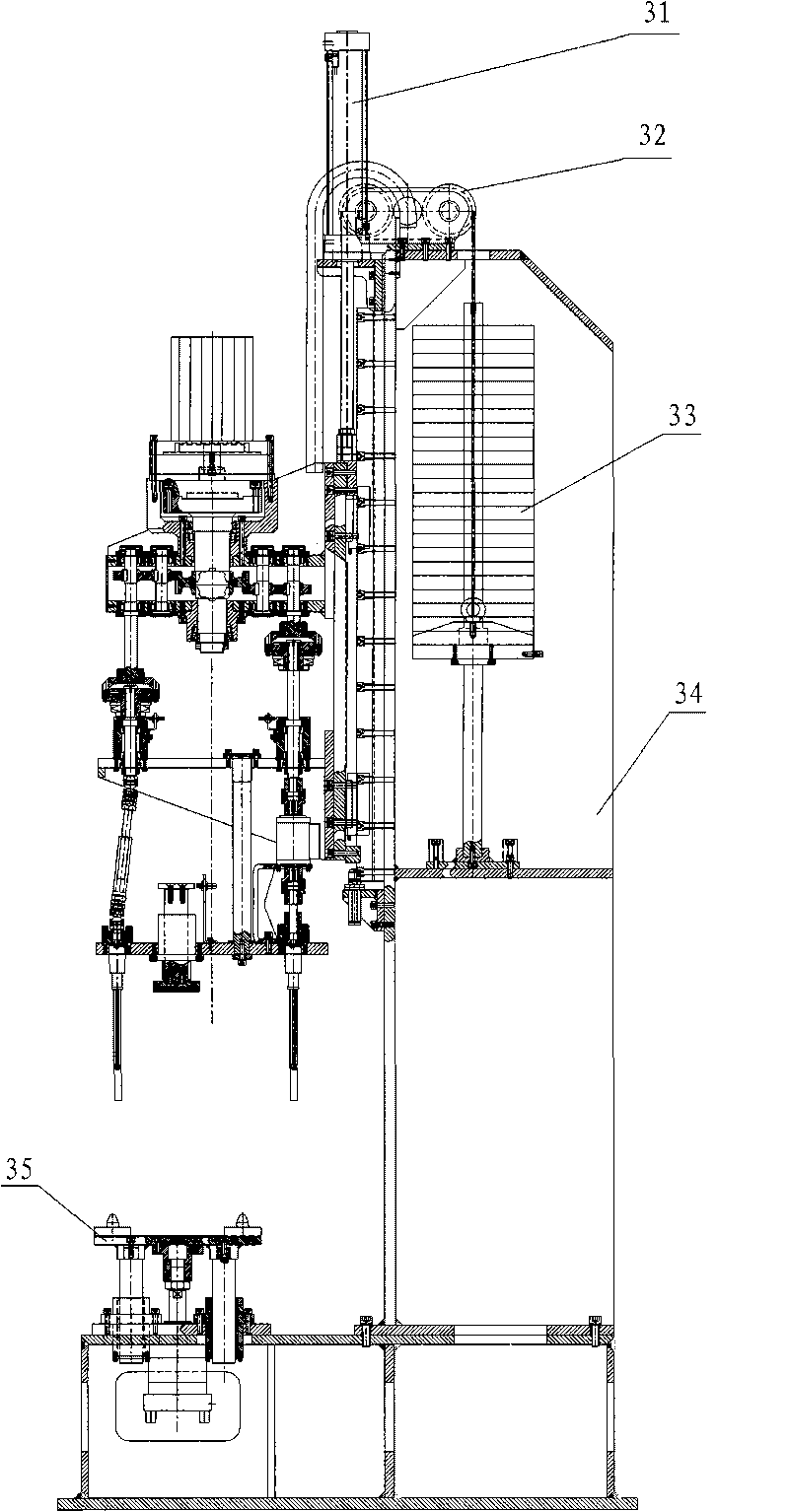

[0022] Such as figure 1 As shown, the present invention includes drive unit, transmission case 5, intermediate shaft 27, torque limiter 23 and tightening head 16, and drive unit is made up of motor 1, speed reducer 2 and speed reducer seat 3. The reducer 2 is installed on the reducer seat 3, and the motor 1 is connected with the reducer 2. One end of the intermediate shaft 27 is connected to the motor 1 through the reducer 2, and the other end passes through the transmission case 5 located below the reducer 2, and the reducer seat 3 is fixed on the transmission case 5; the intermediate shaft 27 is located in the transmission case 5 Part is affixed with intermediate gear 26, is provided with a plurality of transition shafts 6 (the present embodiment is fourteen) in transmission case 5 inside, the periphery of intermediate shaft 27, and transition gear 7 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com