Casting method of spine support pillow with independent built-in spring

A built-in spring, a separate technology, applied to pillows and other directions, can solve the problems of easy damage to the inner material of the pillow, the inability to automatically adjust the height, and affect the quality of sleep, so as to prevent sports inconvenience, improve memory and academic performance, and ensure sleep quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

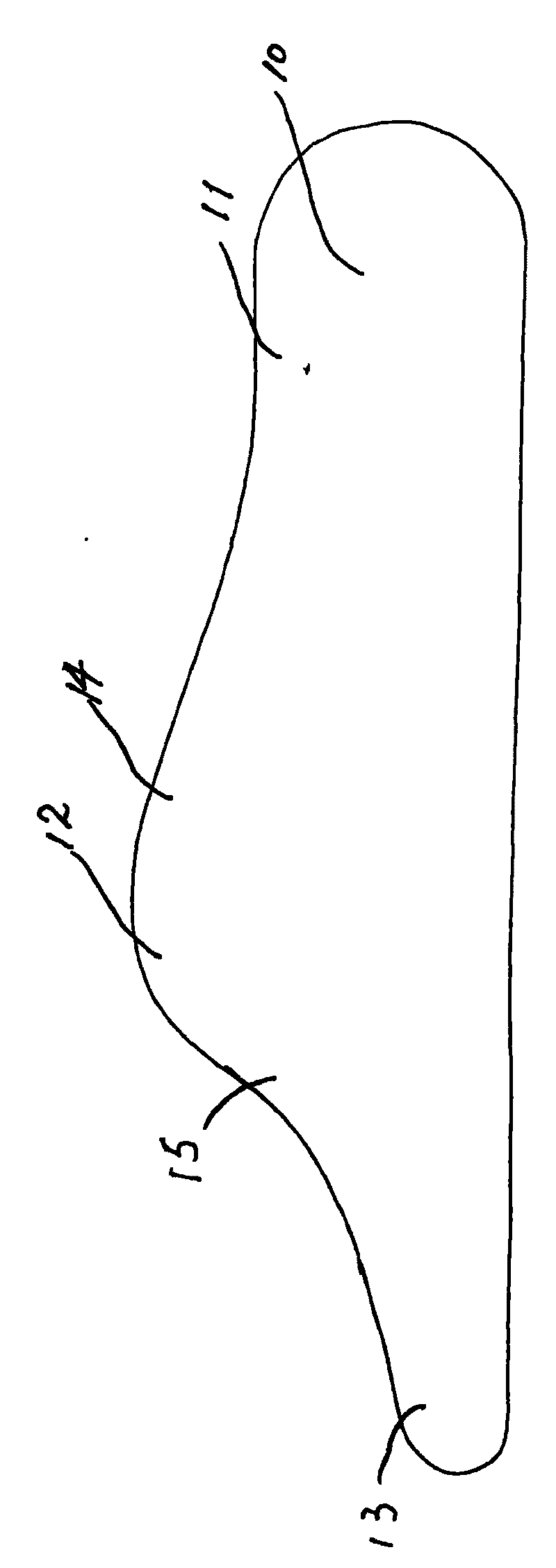

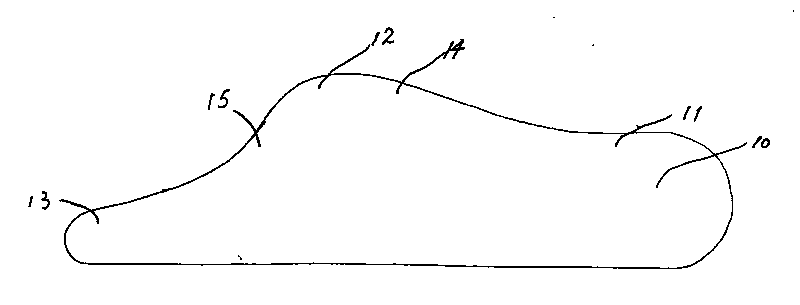

[0008] A casting method for the inner spring of spine protection pillow, which mainly includes the following steps: A: open the mold and clean it; B: assemble the inner spring device - fix the material saving part and the iron sheet with magnet feet on the mold, and then put the The spring is adsorbed on the magnetic feet on the iron sheet; C: inject raw materials into the mold and close the mold; D: open the mold, the spring cast in the pillow and the magnetic feet on the iron sheet are automatically separated. Then take the pillow out of the mold, the spring has been firmly suspended and cast in the pillow alone, leaving beautiful and practical air holes on the surface, and a few magnets for the spring during the casting process are left beside each large hole foot hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com