Mirror surface color coating layer steel plate and processing method thereof

A processing method and color coating technology, which are applied in coatings, chemical instruments and methods, and devices for coating liquid on the surface, etc., can solve problems such as the inability to transfer the color coated steel plate surface, waste of silver resources, and environmental pollution , to achieve the effect of improving the extended use, prolonging the service life, and meeting the requirements of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take the processing of the specular color coated steel plate shown in the accompanying drawing as an example.

[0028] A) uncoiling and docking, the color-coated steel plate substrate 1 that is in the steel coil state and has been coated with the color coating layer 11 on the outward side surface in the use state is uncoiled with an uncoiler, so that the steel coil is unrolled. After uncoiling, the steel strips unfolded on each steel coil are welded head-to-tail by welding, that is to say, the steel strips unfolded on adjacent steel coils are connected to each other to meet the requirements of the subsequent continuous processing process and obtain steel plate to be cleaned;

[0029] B) degreasing cleaning, introducing the steel plate to be cleaned obtained by step A) into a degreasing tank filled with degreasing agent solution for degreasing, in the degreasing tank, the consumption of degreasing agent is 5g / L, the temperature of degreasing agent solution is 70 ℃, steel...

Embodiment 2

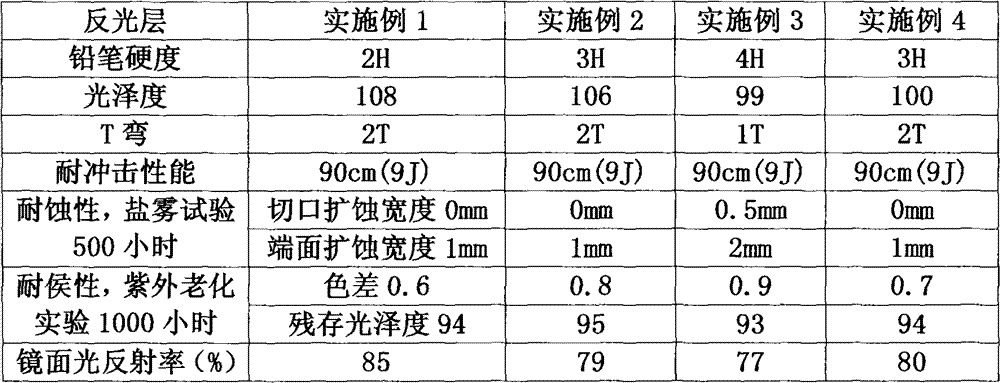

[0034]Only change the amount of the degreasing agent in step B) to 5.5g / L, change the temperature of the degreasing agent solution to 75°C, change the water temperature of the washing tank to 75°C; change the drying temperature in step C) to 85 DEG C; Change the thickness of mirror layer 2 in step D) into 50 μ m, the material used in mirror layer 2 changes into the polyurethane coating that adds the nanometer mirror flour that is 20% and particle diameter is 30-50nm by mass percentage, nanometer The mirror flour is nano-silver powder and nano-aluminum powder with a weight ratio of 1:1. The nano-aluminum powder is selected from the brand MH-Al-50 nano-aluminum powder produced by Nanjing Epurui Co., Ltd., Nanjing, Jiangsu Province, China. The speed is 45m / min, the linear speed of the rubber roller is 67.5m / min, the baking temperature of the oven is changed to 230°C, and the hot air drying temperature is changed to 75°C; the thickness of the reflective layer 3 in step E) is change...

Embodiment 3

[0036] Only change the amount of the degreasing agent in step B) to 4.5g / L, change the temperature of the degreasing agent solution to 65°C, change the water temperature of the washing tank to 65°C; change the drying temperature in step C) to 98 ℃; Change the thickness of the mirror layer 2 in step D) into 12 μm, and the material used in the mirror layer 2 changes into a ring that is 40% and the particle diameter is 35-45nm nano-mirror flour that is nano-magnesium powder. Oxygen coating, the travel speed of the steel strip is changed to 120m / min, the linear speed of the rubber roller is changed to 180m / min, the baking temperature is changed to 190°C, and the hot air drying temperature is changed to 65°C; The thickness of 3 is changed to 12 μm, and the material of the reflective layer 3 is changed to a polyvinylidene fluoride coating with a mass percentage of 20% and a particle size of 40-50nm nano-reflective powder. The nano-reflective powder is selected by weight ratio 1: 1 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com