Ventilating anti-skidding table mat and machining method thereof

A processing method and anti-slip technology, which is applied in the processing of breathable anti-slip placemats and the field of breathable anti-slip placemats, can solve the problems of lack of air permeability and anti-slip properties, and meet the requirements of process and equipment without pickiness, concise steps, good anti-slip and The effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

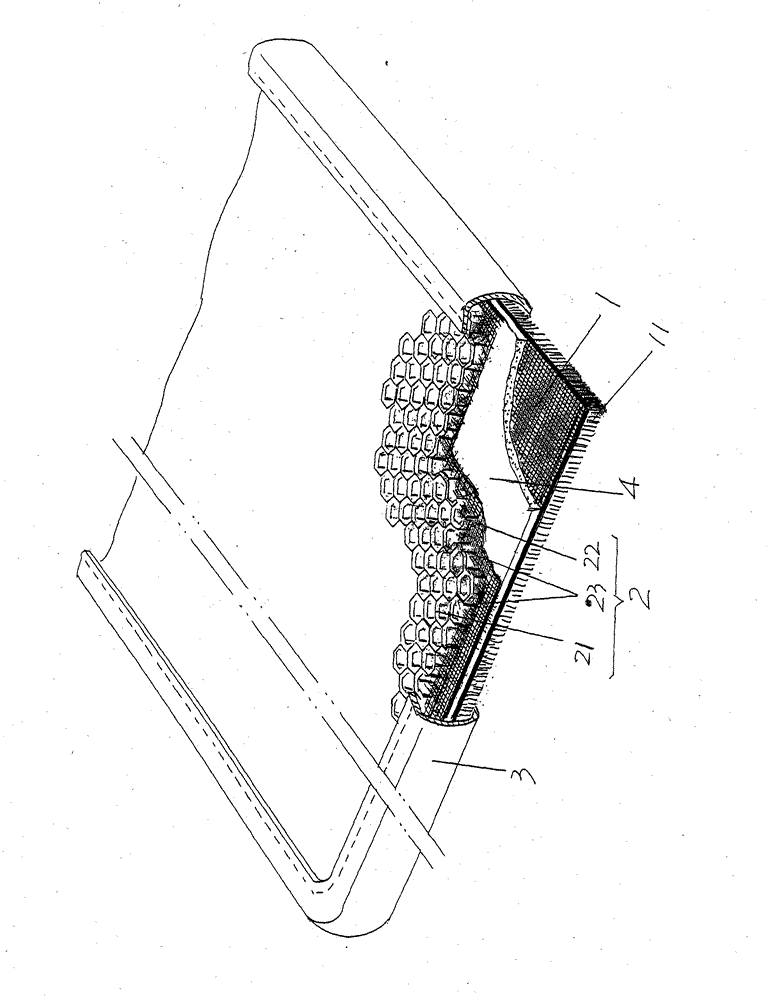

[0026] please see figure 1 , figure 1 The manufacture of the breathable non-slip placemat of the shown structure comprises the following steps:

[0027] A) raw material selection, select the fabric that is processed by polyester-nylon composite yarn and the surface and the back facing outwards and facing upwards in the use state are all formed with a soft layer 11 served by a fluff layer as the front structural layer 1, the front surface The grammage of structural layer 1 is 210g / m 2 , the selection mesh number (density range) is 18 meshes and the sponge that thickness is 2mm is used as filling layer 4, selects the material that adopts double-needle bar warp knitting process to obtain to be polyester by the plain cloth weaving layer 22 of surface layer, the mesh of bottom layer A hollowed-out mesh in the form of a sandwich structure composed of the braided layer 21 and the mid-filament connecting layer 23 between the plain cloth braided layer 22 and the mesh braided layer 21...

Embodiment 2

[0032] Only change the softness layer 11 of the front structure layer 1 in step A) to be served by the pile layer, and the grammage of the front structure layer 1 is changed to 300g / m 2 , change the weight of the back structure layer 2 to 150g / m 2 , change the thickness to 2mm; change the heating compound temperature in step B) to 220°C; change the size in step C) to 30cm×30cm; change the temperature of the glue in step D) to 240°C, and the rest are the same Description of Example 1.

Embodiment 3

[0034] Only change the flexible layer 11 of the front structure layer 1 in step A) to be served by the pile layer, and the grammage of the front structure layer 1 is changed to 260g / m 2 , change the weight of the back structure layer 2 to 1500g / m 2 , change the thickness to 20mm; change the heating compound temperature in step B) to 210°C; change the size in step C) to 50cm×60cm; change the temperature of the glue in step D) to 215°C, and the rest are the same Description of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com