Ventilating anti-skidding table mat and machining method thereof

A processing method and anti-slip technology, which is applied in the processing of breathable anti-slip placemats and the field of breathable anti-slip placemats, can solve the problems of lack of air permeability and anti-slip properties, and meet the requirements of process and equipment without pickiness, concise steps, good anti-slip and The effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

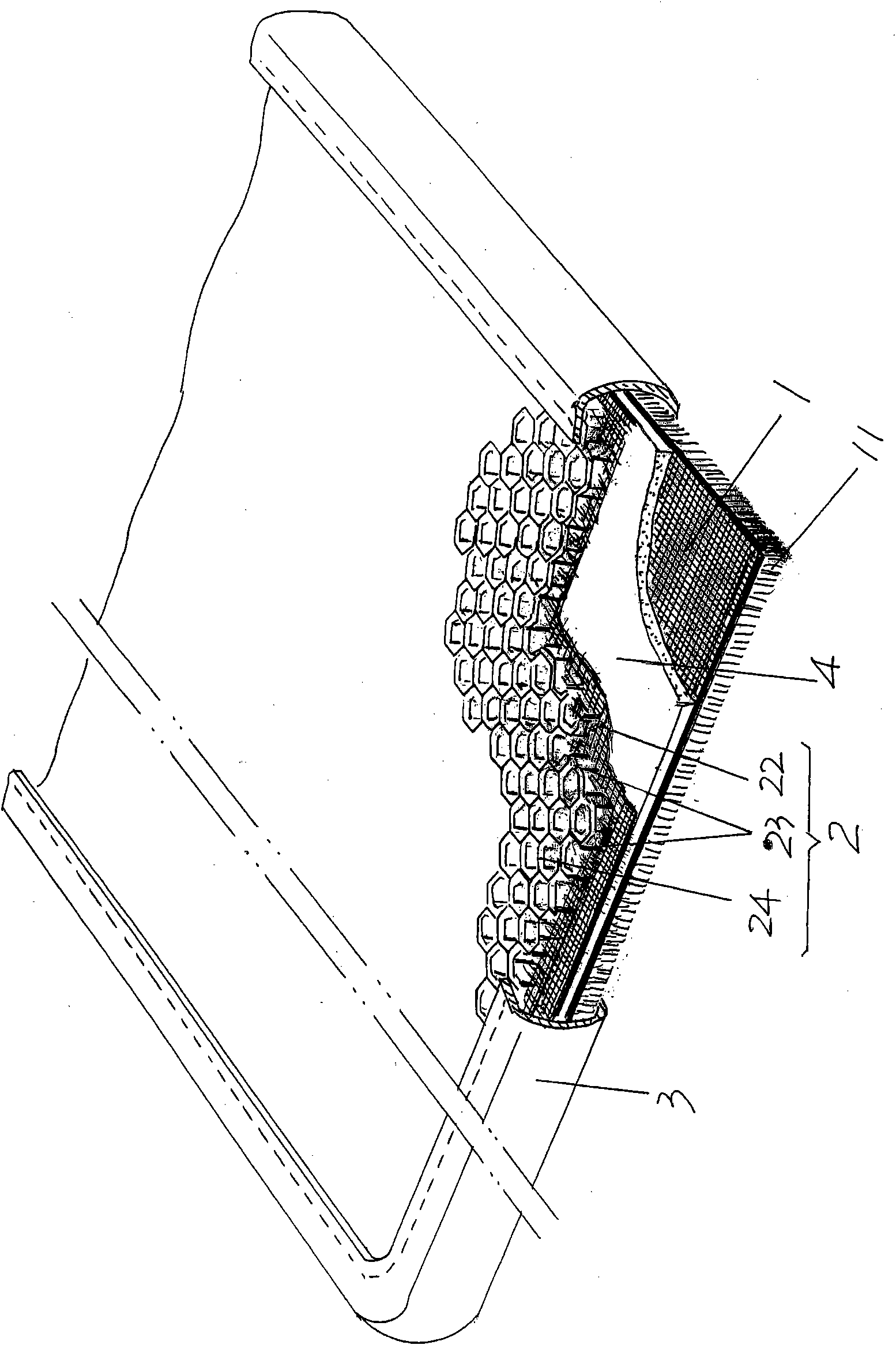

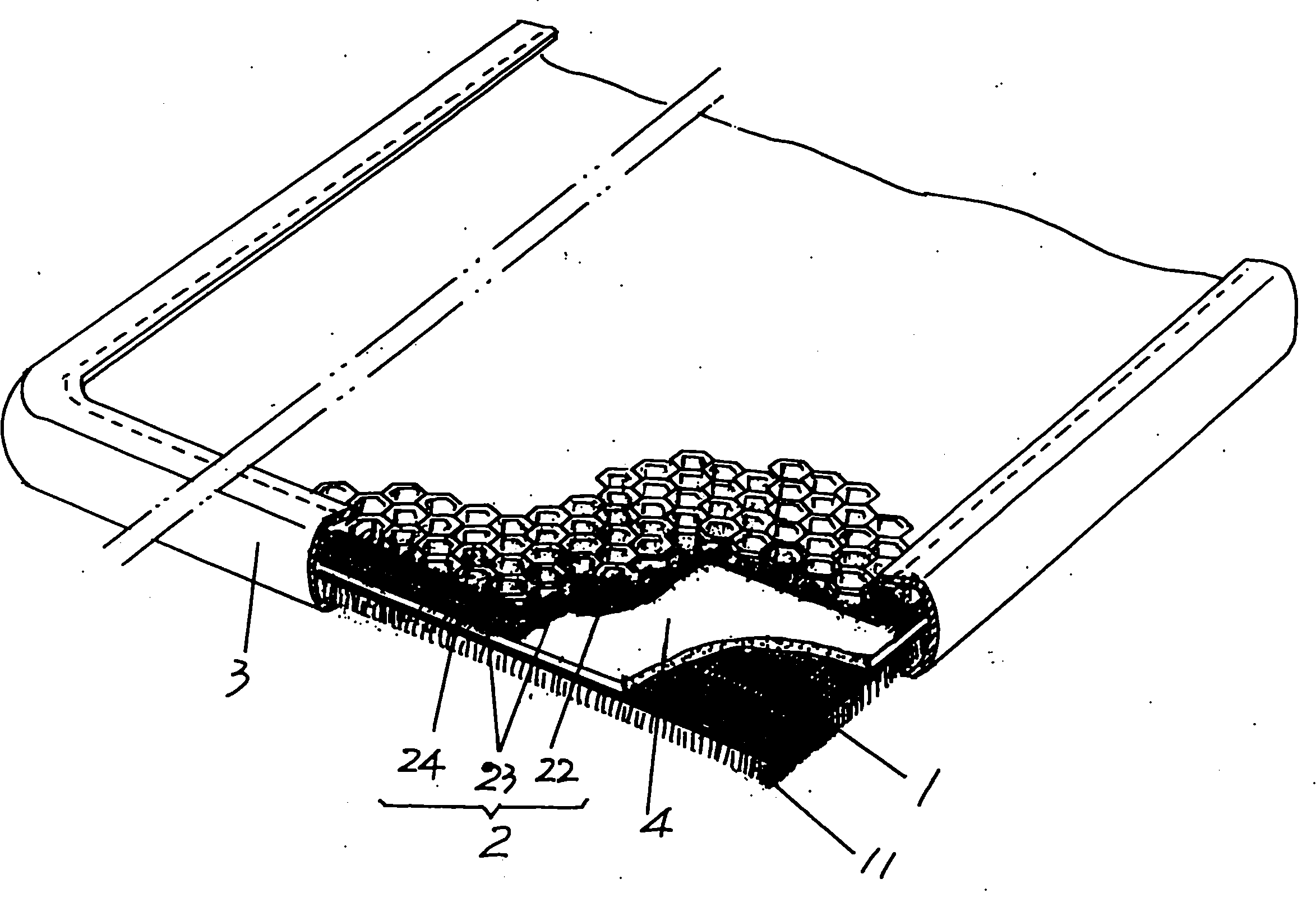

[0026] Please see figure 1 , figure 1 The production of the breathable non-slip placemat of the structure shown includes the following steps:

[0027] A) Raw material selection, select the fabric which is made of polyester / nylon composite yarn and which faces outwards, that is, upwards in the use state, which has a soft layer 11 filled with fluff layer as the front structure layer 1. The weight of structural layer 1 is 210g / m 2 , Choose a sponge with a mesh number (density range) of 18 mesh and a thickness of 2mm as the filling layer 4, and select the material obtained by the double needle bed warp knitting process to be polyester with the surface layer of the plain cloth woven layer 22, the bottom mesh The woven layer 21 and the hollow mesh in the form of a sandwich structure formed by the middle wire connecting layer 23 between the plain cloth woven layer 22 and the mesh woven layer 21 for connecting the plain cloth woven layer 22 and the mesh woven layer 21 The cloth is used...

Embodiment 2

[0032] Only the flexible layer 11 of the front structure layer 1 in step A) is replaced by a pile layer, and the weight of the front structure layer 1 is changed to 300g / m 2 , Change the weight of the back structure layer 2 to 150g / m 2 , The thickness is changed to 2mm; the heating compound temperature in step B) is changed to 220°C; the size in step C) is changed to 30cm×30cm; the glue temperature in step D) is changed to 240°C, and the rest are the same Description of Example 1.

Embodiment 3

[0034] Only the flexible layer 11 of the front structure layer 1 in step A) is replaced by a loop layer, and the weight of the front structure layer 1 is changed to 260g / m 2 , Change the weight of the back structure layer 2 to 1500g / m 2 , The thickness is changed to 20mm; the heating compound temperature in step B) is changed to 210°C; the size in step C) is changed to 50cm×60cm; the glue temperature in step D) is changed to 215°C, and the rest are the same Description of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com