Gear drive mechanism in wing mirror reverse of automobile

A technology of gear transmission mechanism and automobile rearview mirror, which is applied in optical observation devices, vehicle parts, transportation and packaging, etc., can solve problems such as large noise, large torque, and loud motor noise, and achieve avoidance of redesign, low noise, and slow speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

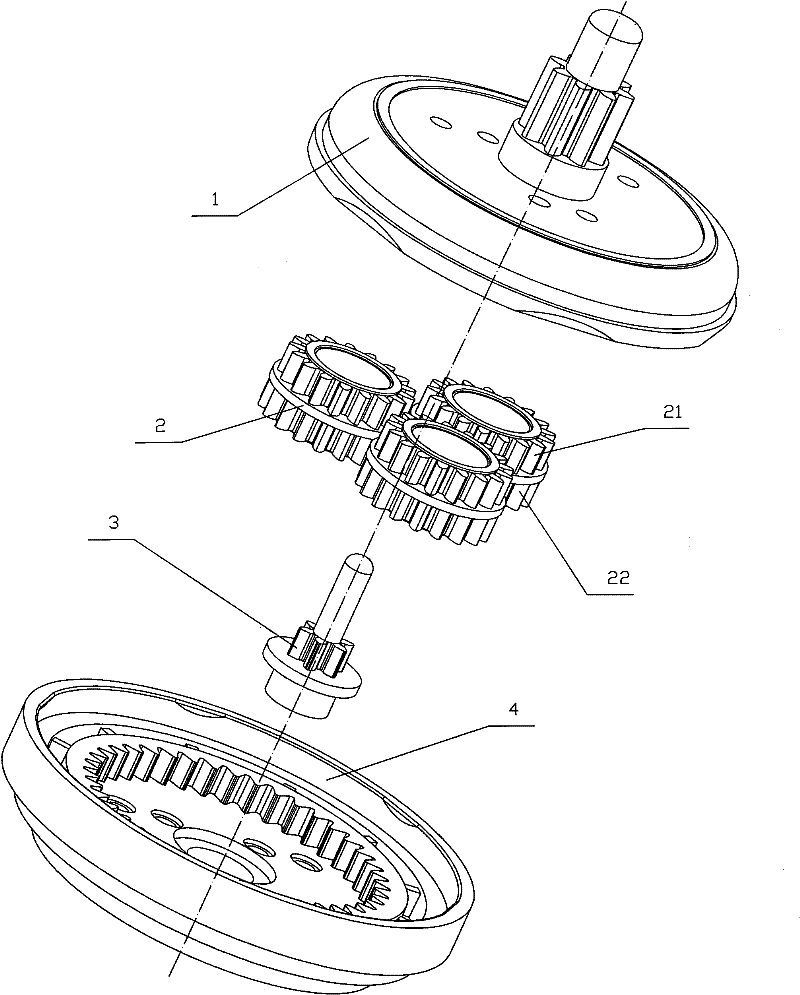

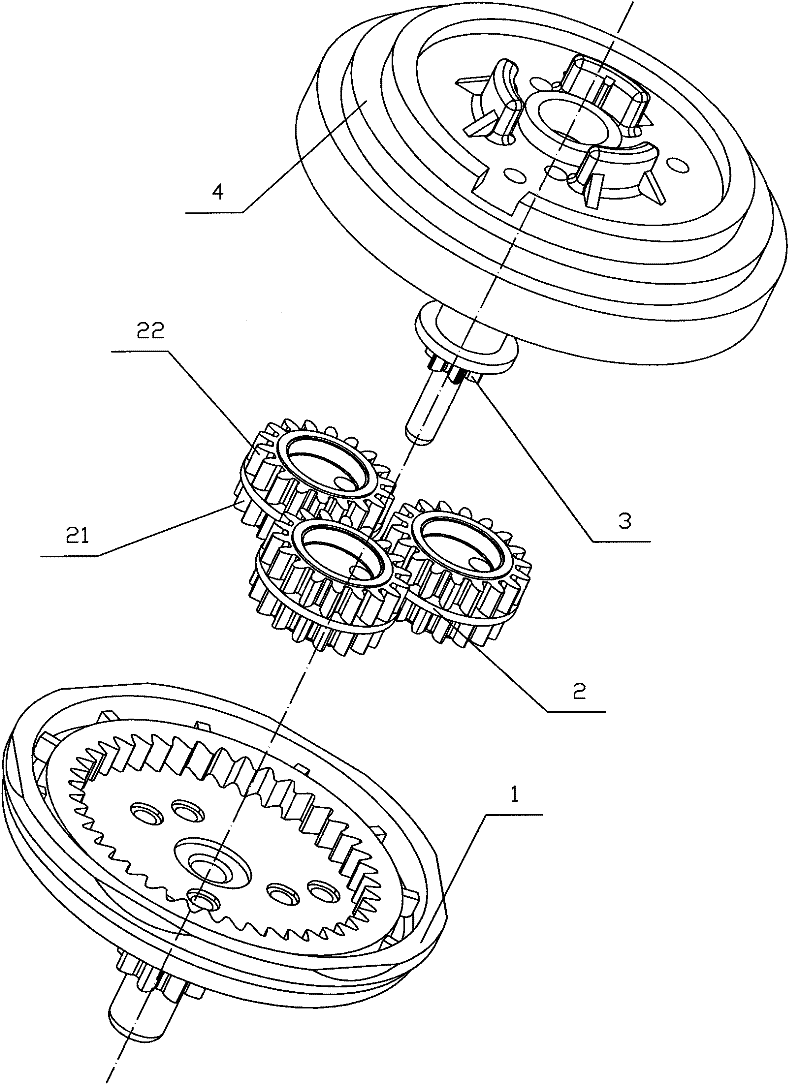

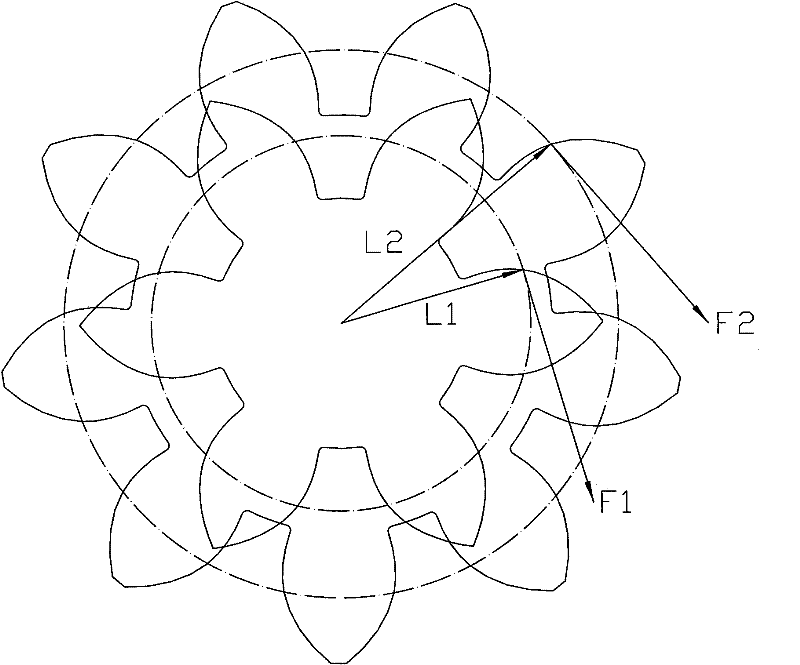

[0014] Depend on figure 1 , figure 2 As can be seen from the exploded schematic diagram of the gear transmission mechanism in the automobile rearview mirror reversing device of the present invention, it includes three planetary gears 2, a central gear rod 3, a gear box upper cover 1 with an internal ring gear and a gear box under the gear box. Cover 4, the gear case upper cover 1 is connected with the gear case lower cover 4. The plurality of planetary gears 2 are dual gears with upper and lower layers, which are upper planetary gears 21 and lower planetary gears 22 respectively. The upper planetary gears 21 mesh with the inner ring gear of the gearbox loam cake 1, so The lower planetary gear 22 mentioned above meshes with the ring gear of the lower cover 4 of the gearbox. The sun gear rod 3 is located in the middle of a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com