Resin composition for film insert molding and molded product

A technology of resin composition and insert molding, which is applied in the field of resin composition for film insert molding and its molded products, and can solve the problems of not disclosing the resin composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0134] Any method may be adopted for the production of the thermoplastic resin composition of the present invention. For example, the method of premixing A component, B component, and other components, melt-kneading, and granulating is mentioned. As the means of premixing, a Nauta (NAUTA) mixer, a V-blender, a Henschel mixer, a mechanochemical device, an extrusion mixer, etc. are mentioned. In premixing, granulation may be performed using an extrusion granulator, a briquetting machine, or the like as needed. After premixing, melt kneading is performed using a melt kneader represented by a vented twin-screw extruder, and granulation is performed using a machine such as a granulator. As the melt-kneading machine, a Banbury mixer, a kneading roll, a constant-temperature stirring vessel, etc. may also be mentioned, but a vented twin-screw extruder is preferable.

[0135] In addition, a method of independently supplying each component to a melt-kneader represented by a twin-screw...

Embodiment 1-11、 comparative example 1-5

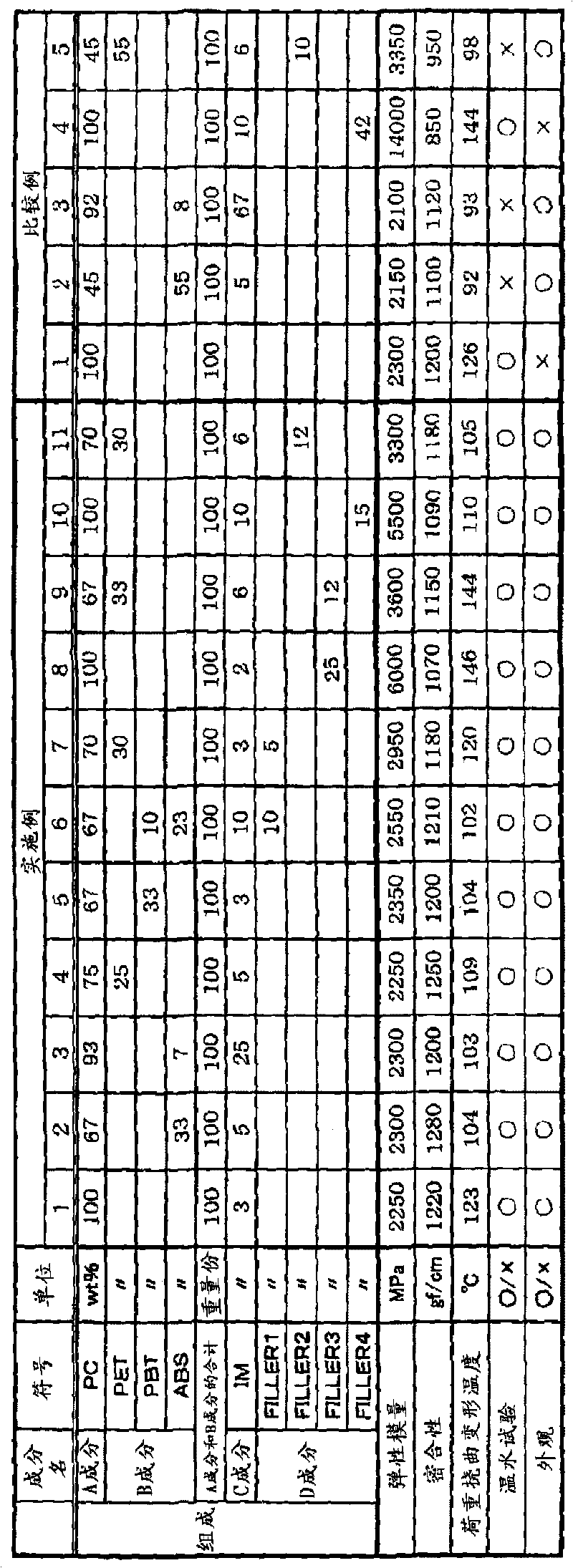

[0208] Each evaluation result of Examples 1-11 and Comparative Examples 1-5 is described in Table 1.

[0209] [Table 1]

[0210]

[0211] As shown in Examples 1-11, the resin composition of the present invention has a flexural modulus of 2,200 MPa or more and less than 12,000 MPa as measured in accordance with ISO-178, and the film insert molded product not only has excellent appearance, but also has excellent adhesion, and The impact resistance was excellent, and the deflection temperature under load was high, and no problems occurred in the warm water test.

[0212] Comparing Example 1 and Comparative Example 1, it can be seen that if no impact modifier is incorporated into the film insert molded product, wrinkles will be generated. Comparing Examples 2 and 3 with Comparative Examples 2 and 3, it can be seen that when the components B and C are contained in a large amount, the elastic modulus is 2,200 MPa or less, and the deflection temperature under load is lowered, res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com