Construction process for double-block ballastless track bed on subgrade

A technology of ballastless track and construction technology, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of less maintenance time, poor track smoothness, and hindering the development of high-speed railways, so as to improve construction quality and laying accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

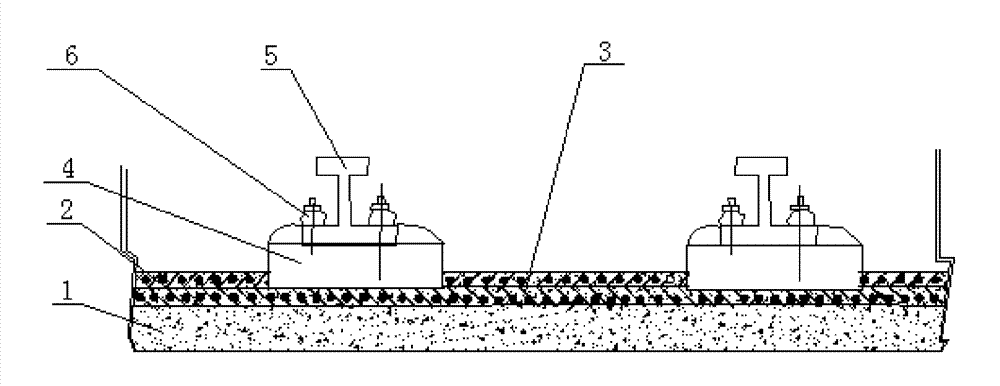

Image

Examples

Embodiment Construction

[0046] The specific implementation is as follows:

[0047] A construction technique for subgrade double-block ballastless track bed, which comprises the following steps:

[0048] The first step is to ensure that the subgrade settlement meets the construction requirements:

[0049] The second step is to clean the foundation surface of the subgrade:

[0050] Remove scum, dust and debris from the foundation surface of the subgrade;

[0051] The third step is to construct the concrete support layer 1 with the slide film paver:

[0052] a) Measurement and release of supporting layer:

[0053] Test the position of the guide lines on both sides of the support layer through the CPIII control network, and the guide lines are located on the paver

[0054] On both sides; the distance from the guide line to the center line of the line is 2.9m, and the height is 50cm from the designed subgrade surface; the longitudinal distance between the guide line rods is 10m, and the curve section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com