Solid wood composite floor board baseplate and manufacturing method thereof

A technology of solid wood composite flooring and manufacturing methods, which is applied in the direction of manufacturing tools, building structures, wood processing appliances, etc., which can solve the problems of poor bending resistance, large internal stress deformation, unevenness, etc., and achieve uniform internal stress and small deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] The following describes the structure and manufacturing method of the present invention in detail with reference to the accompanying drawings:

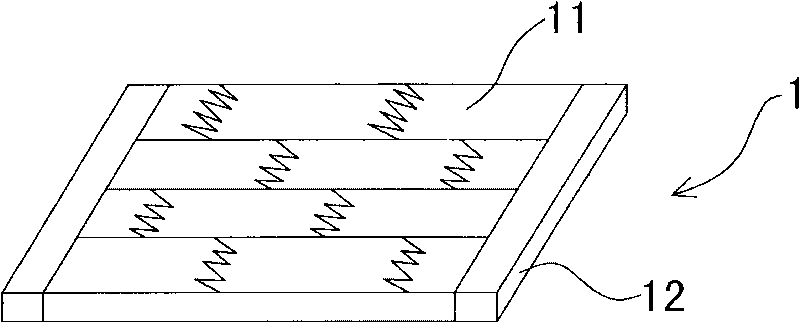

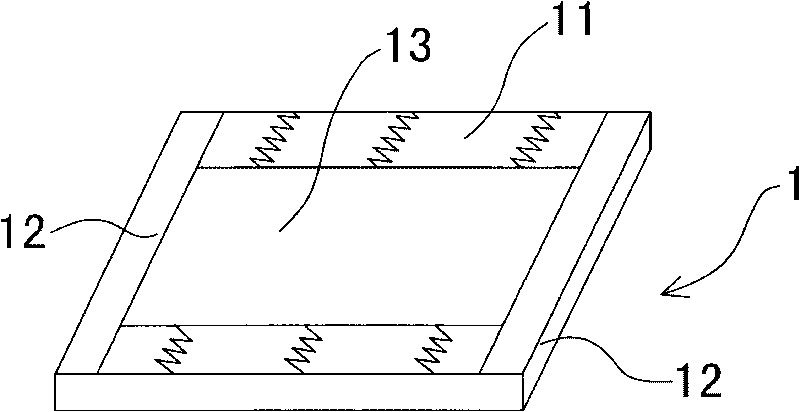

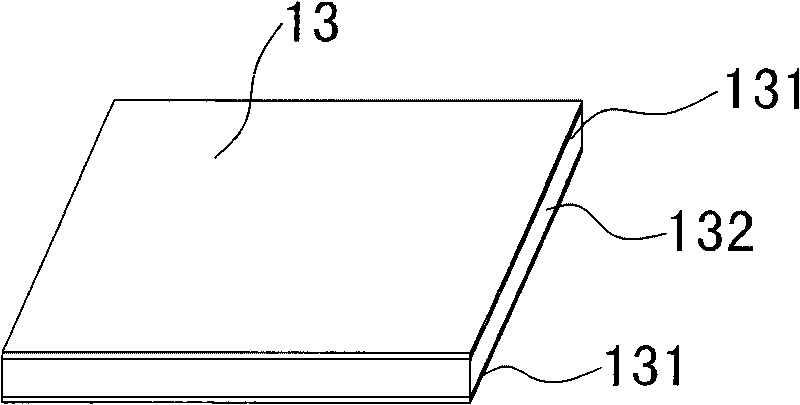

[0036] See figure 1 with Figure 4 In the first specific embodiment shown in the figure, the present invention discloses a solid wood composite floor substrate, which is connected by a plurality of finger-joined integrated slats 11 laterally bonded and connected, and then the two ends are vertically bonded and connected respectively. Integrated slats 12, the longitudinal integrated slats can be selected as finger-joined integrated slats or wooden slats. After the horizontal and vertical connection of the integrated slats is completed, the upper and lower sides are attached to a reinforcing layer 2 and 3 respectively, so that the longitudinal integrated board The strips and the individual integrated strips in the horizontal integrated strips are fully pasted up, down, left, and right. The strengthening layer can choose veneer such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com