Receiving method for pipe pusher obliquely entering narrow receiving well in underground pipe pushing construction

A technology for receiving shafts and pipe jacking machines, which can be used in earth drilling, mining equipment, tunnels, etc., and can solve problems such as narrow construction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

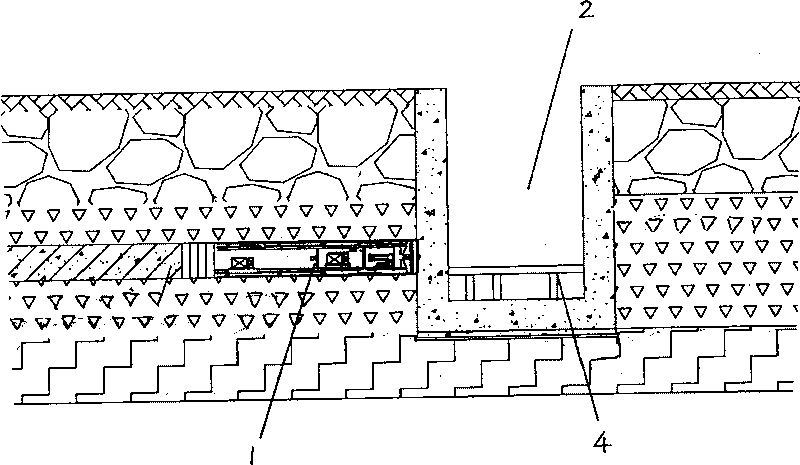

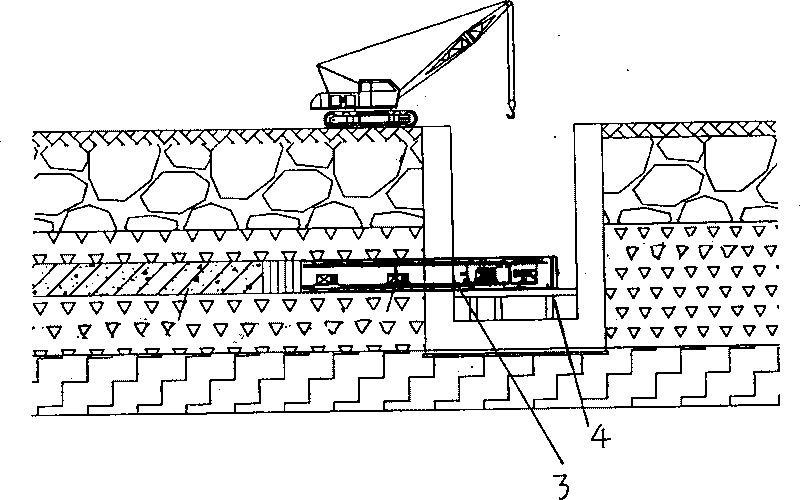

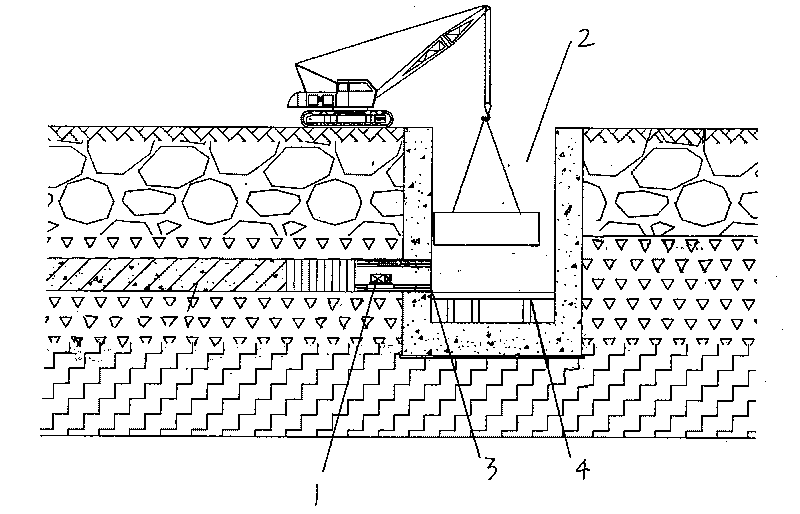

[0008] When the pipe jacking machine 1 approaches the receiving well 2, a door 3 is dug on the receiving well 2 relative to the pipe jacking machine 1 on the pipeline, and a receiving frame 4 is built in the receiving well 2, and then the front end of the pipe jacking machine 1 rests on the The power unit part at the rear end enters the receiving tire frame 4 in the narrow receiving shaft 2, and after properly reinforcing the outer steel shell of the front end of the pipe jacking machine 1, first remove the pipe jacking machine parts connected to the steel shell of the pipe jacking machine 1 And transported away from the receiving well 2, after confirming that there is no component of the pipe jacking machine 1 within the projection range of the receiving well 2, cut off the outer steel shell of the pipe jacking machine 1 in the receiving well 2, and lift it away from the receiving well 2, and then lift After the pipe jacking machine 1 again relies on the power unit at the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com