Spar edge strip system of wind turbine rotor blade and method for manufacturing rotor blade

A technology for wind turbines and rotor blades, which is applied in the field of spar cap systems, and can solve the problems of rotor blades such as heavy strength, high cost, and high design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

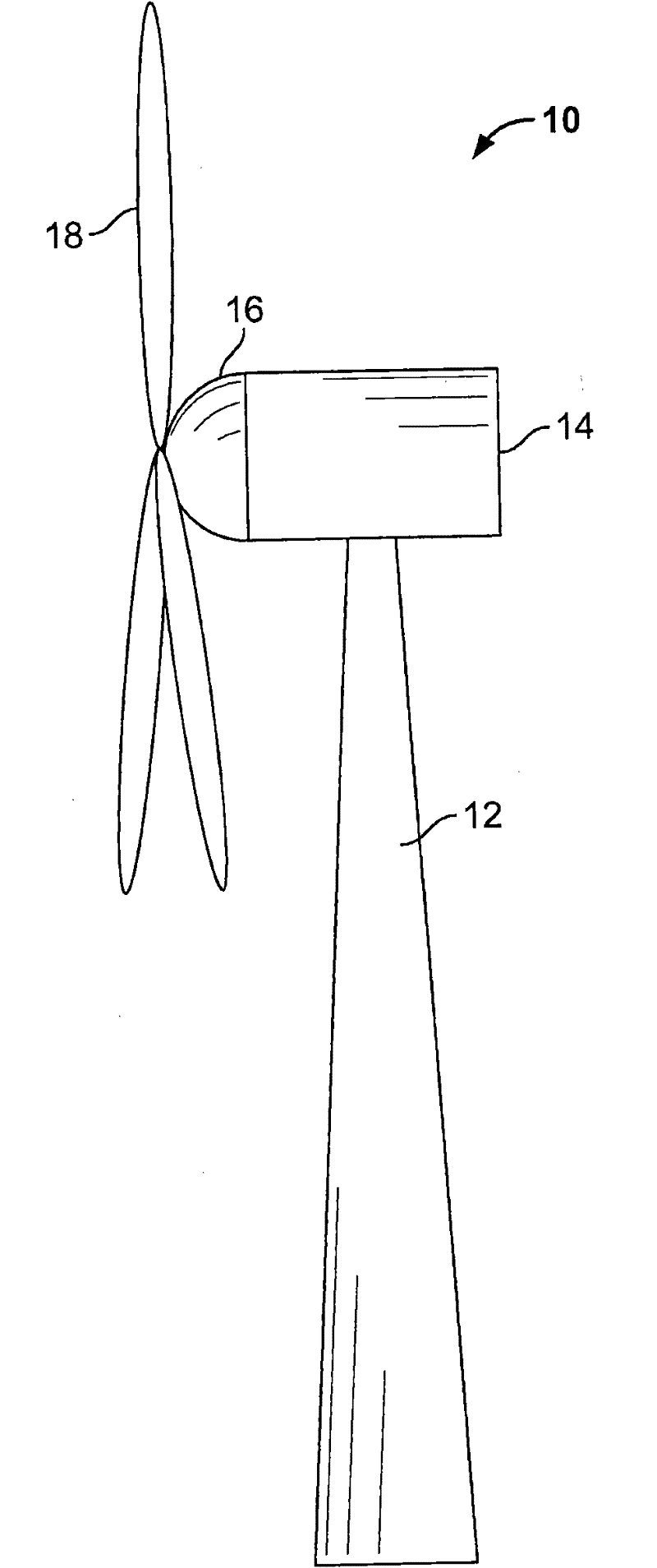

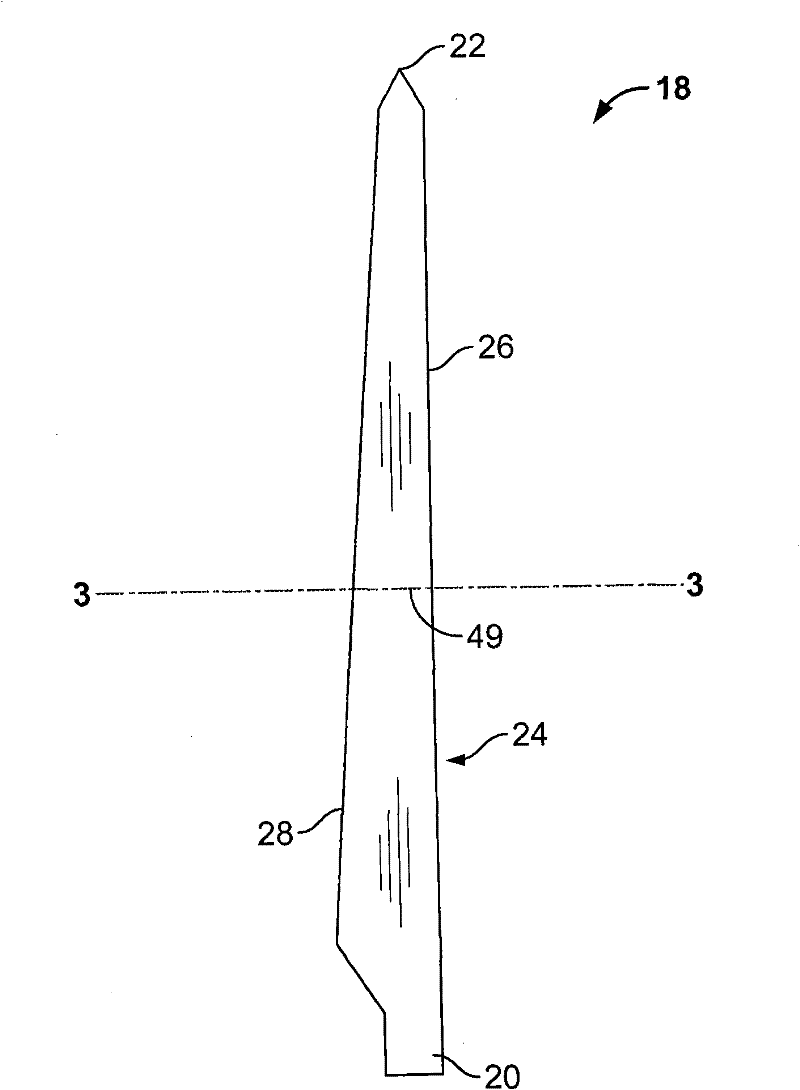

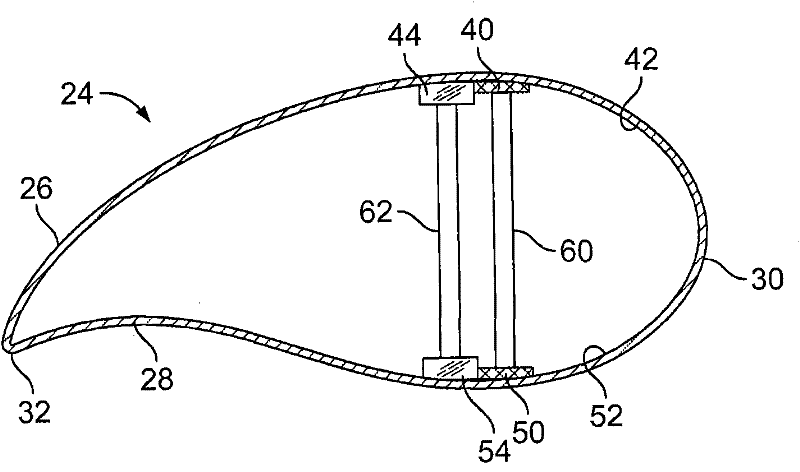

[0039] Embodiments described herein provide a rotor blade for a wind turbine comprising a sparcap system adapted to provide sufficient strength to the rotor blade while reducing the overall weight and / or manufacturing costs of the rotor blade. The sparcap system includes a first sparcap and a second sparcap, the first sparcap comprising a carbon material positioned on and coupled to an inner surface of the rotor blade first blade section, A second sparcap comprising a glass material is positioned adjacent to the first sparcap and coupled to the first blade section and is positioned forward relative to the first sparcap along the cross-sectional width of the rotor blade. edge direction or trailing edge direction. The use of a first sparcap comprising a carbon material and a second sparcap comprising a glass material adjacent to the first sparcap allows for the manufacture of longer and / or larger rotor blades while reducing the The spar cap mass and blade static moment, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com