Explosion venting bolt fastener for pressure relief facility

A technology of bolt fasteners and explosion venting, which is applied in the direction of mechanical equipment, engine components, and functional valve types, etc., can solve the problems of not having self-tapping heads, rusting of explosion venting bolt fasteners, and the thickness should not be too thick. Achieve the effects of avoiding chemical corrosion and rust, reducing installation workload, and strengthening waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

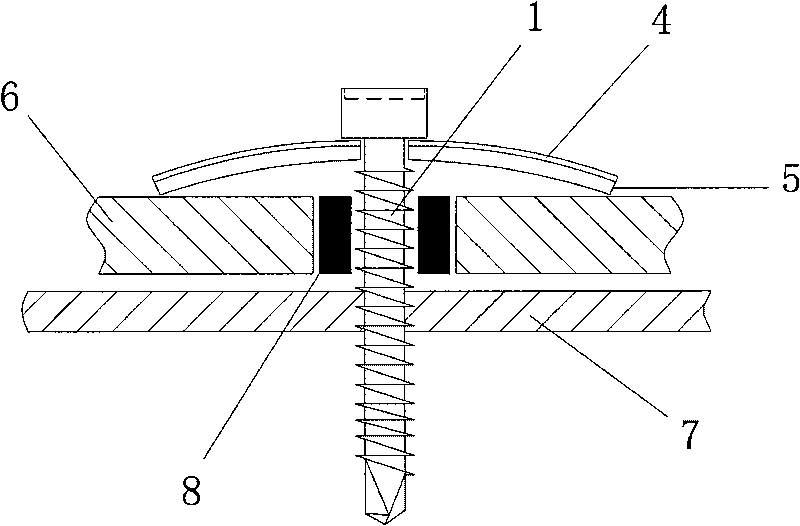

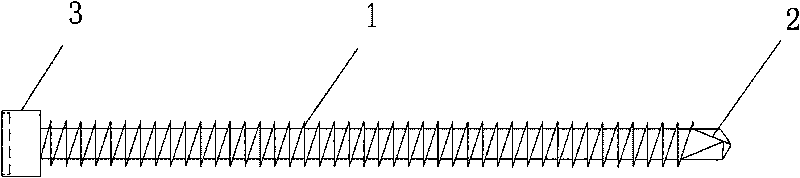

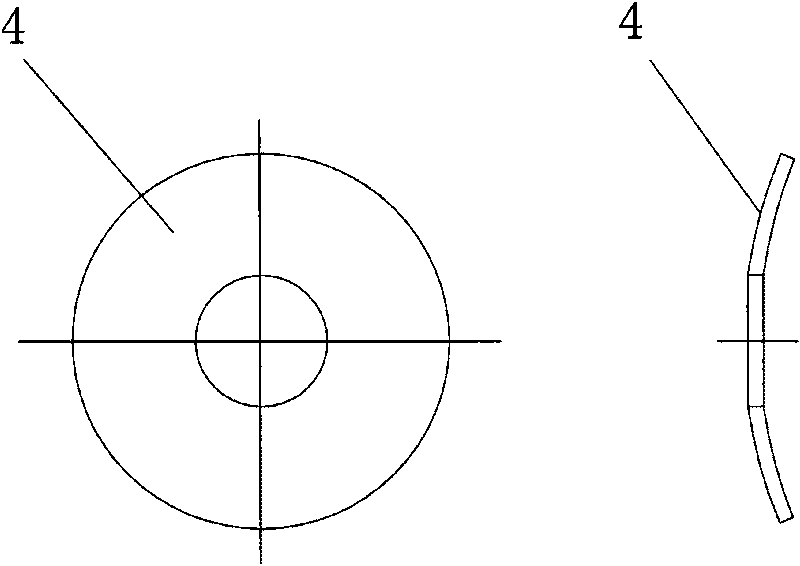

[0022] Such as figure 1 As shown, before the explosion occurs, the explosion-venting bolt fastener 20 is in a non-working state. It can be seen that the explosion-venting bolt fastener 20 is composed of a metal gasket 4 , a screw rod 1 and an elastic gasket 5 . Before installation, a hole is first opened on the outer wall panel 6 for the screw rod 1 to pass through, and then the fastener, the outer wall panel 6 and the structural wall beam 7 are matched and installed in sequence. During this process, because the end of the screw rod 1 has a self-tapping head 2, the self-tapping function can be realized. In addition, there is a rubber sleeve 8 between the screw rod 1 and the outer wall panel 6 to strengthen the cooperation between the two. Elastic washer 5 (this elastic washer also adopts rubber, also can other material) is attached to the below of metal washer 4 according to this radian, and elastic washer 5 preferably EPDM layer. The arc angle combination of the metal gask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com