Pulverized coal furnace tiny-oil ignition combustion method

A technology of micro-oil ignition and combustion method, which is applied in the direction of combustion method, burner, combustion ignition, etc., which can solve the problems of inability to ignite with less oil in the flame cyclone, dense and dilute phase pulverized coal burner, etc., and achieve the adaptability of a wide range of coal types , simple system structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

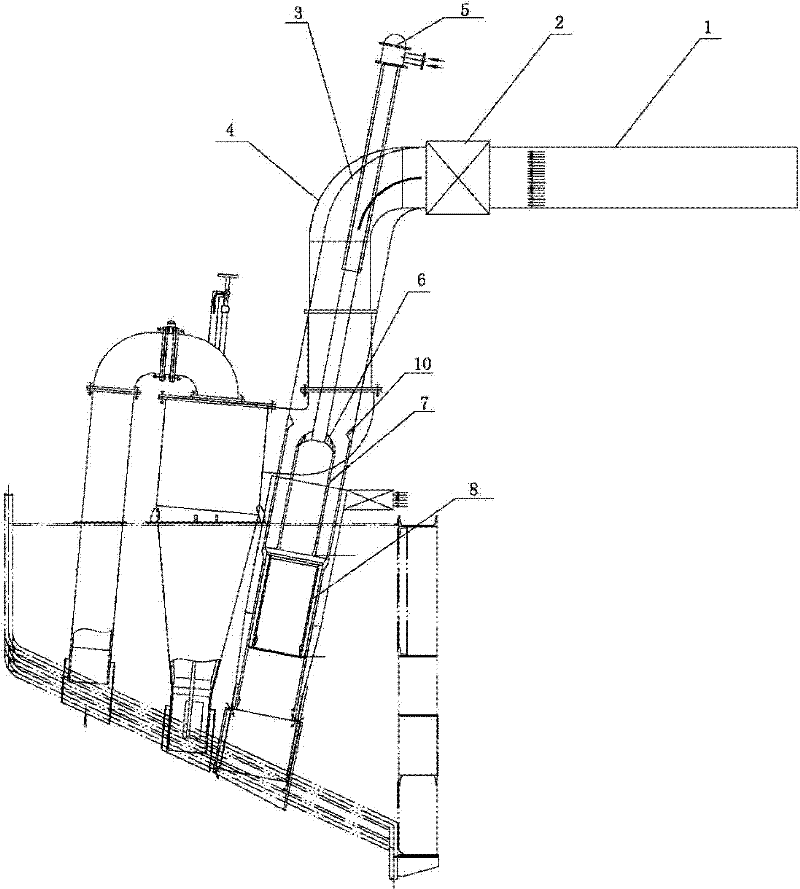

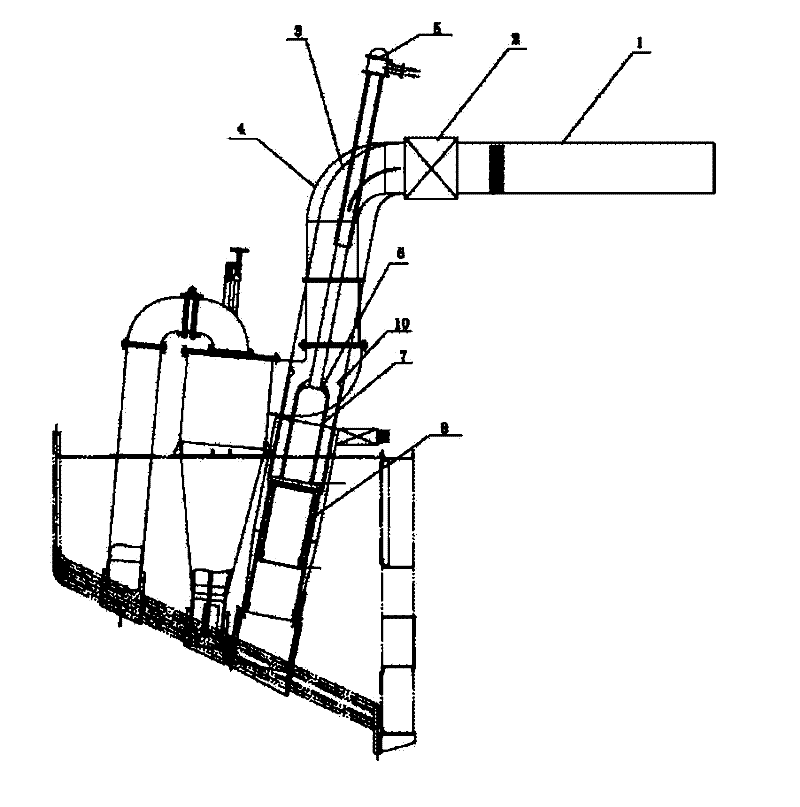

[0031] The present invention is described in detail below in conjunction with accompanying drawing, as figure 1 Shown:

[0032] 1] Lead the pulverized coal airflow conveyed by the main pulverized coal pipeline 1 into the micro-oil ignition combustion device arranged in the first auxiliary pulverized coal pipeline 3 to perform micro-oil ignition;

[0033] 1.1] The pulverized coal airflow passes through the main pulverized coal pipeline 1 to the switching door 2. The switching door 2 opens the side passage of the first auxiliary pulverized coal pipeline 3, and closes the side passage of the second auxiliary pulverized coal pipeline 4. The pulverized coal airflow from the main pulverized coal pipeline 1 is sent into the first secondary pulverized coal pipeline 3, and a micro-oil ignition device 5 is arranged in the first secondary pulverized coal pipeline 3, and the micro-oil igniter 5 can be connected with the first secondary pulverized coal pipeline. Pipeline 3 coaxial setting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap