Inductor improved structure

An improved structure and inductor technology, applied in transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, inductor with magnetic core, etc., can solve problems such as vibration and noise, improve time, speed up production process, The effect of avoiding human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

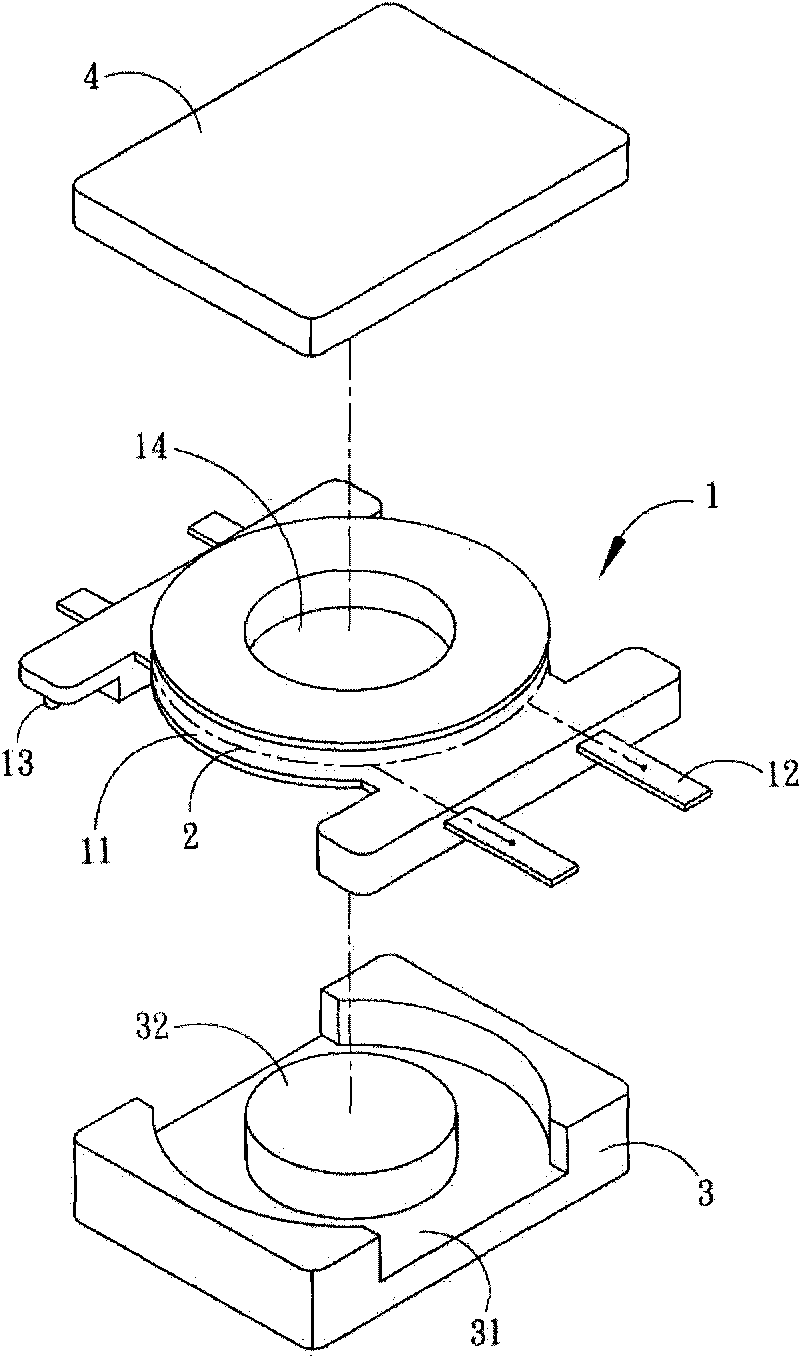

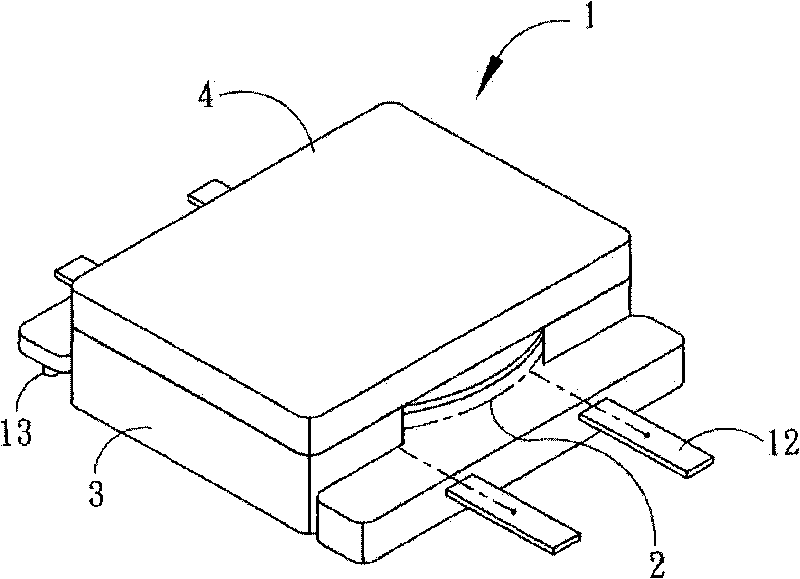

[0026] see Figure 1 to Figure 3 A modified structure of an inductor is shown, mounted on a circuit board 5 . The inductor mainly includes a wire frame 1 , a coil 2 , an iron core 3 and a cover 4 .

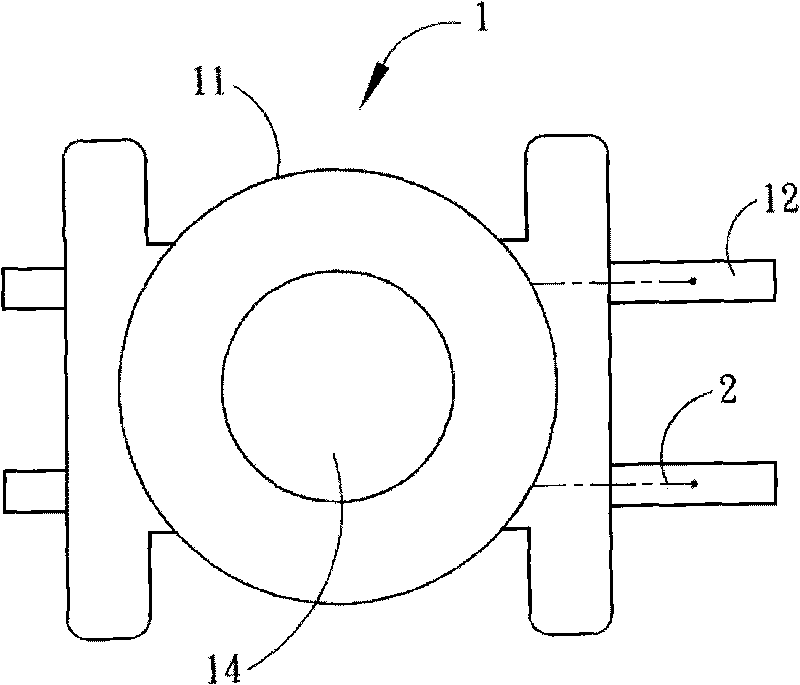

[0027] The wire frame 1 is made of insulating material, such as plastic molding. A winding area 11 is arranged in the bobbin frame 1 , and the winding area 11 is designed in a horizontal ring, so as to provide the coil 2 to be wound horizontally in a ring. Terminals 12 are arranged around the wire frame 1 , and the two ends of the coil 2 are connected to the terminals 12 to generate an inductance function. A positioning rod 13 is further arranged around the wire frame 1 , and the positioning rod 13 is used for fast positioning on the circuit board 5 .

[0028] The iron core 3 is provided with a slot 31, and a boss 32 is arranged in the slot 31, and a perforation 14 is arranged in the center of the wire frame 1 surrounded by the coil 2, so that the wire frame 1 is sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com