Highly-efficient wire breaking terminal

A wire breaking and terminal technology, which is applied in the field of electrical connection devices, can solve the problems of increasing maintenance difficulty, prolonging maintenance time, cumbersome wire breaking operation, etc., and achieves the effect of simple structure, simple and fast wire breaking process, and shortened operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

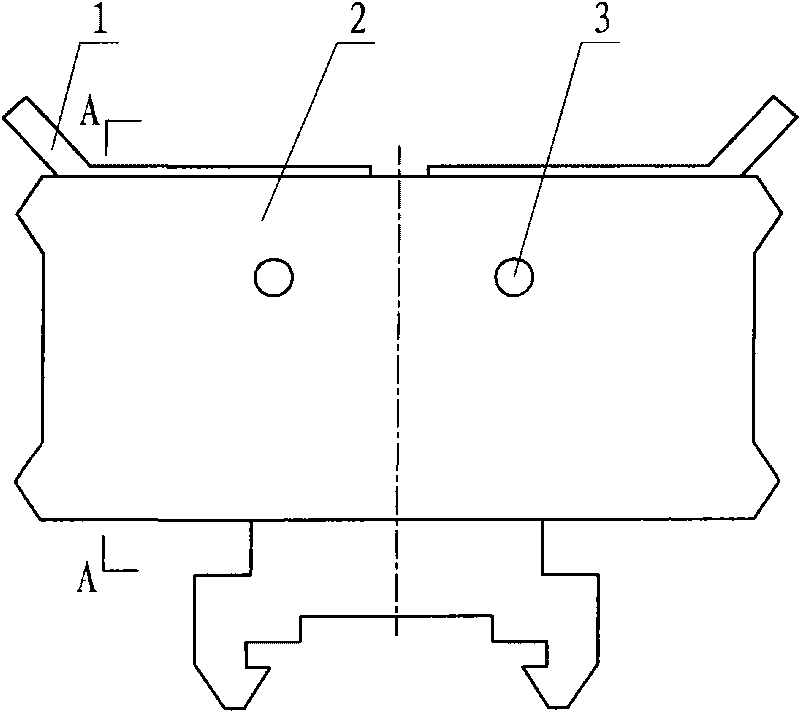

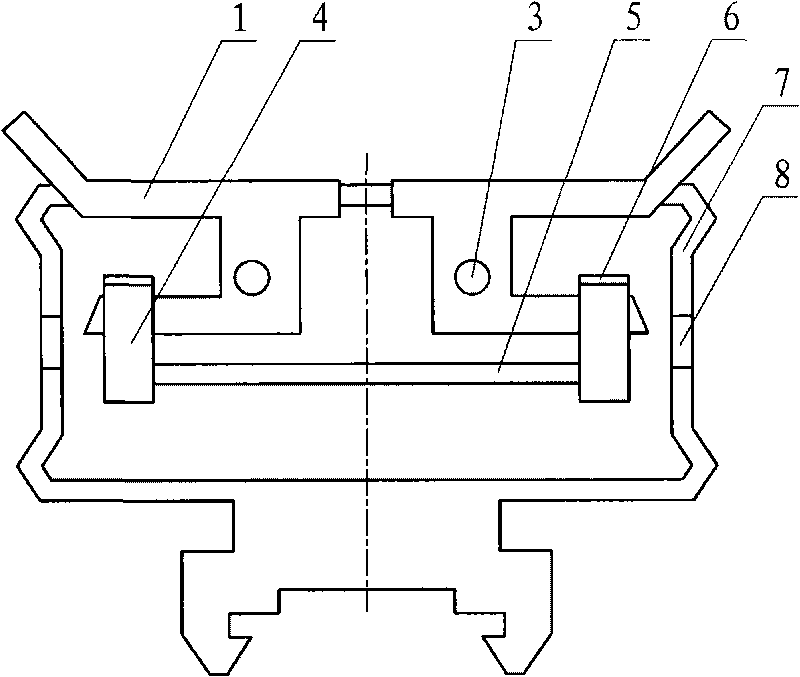

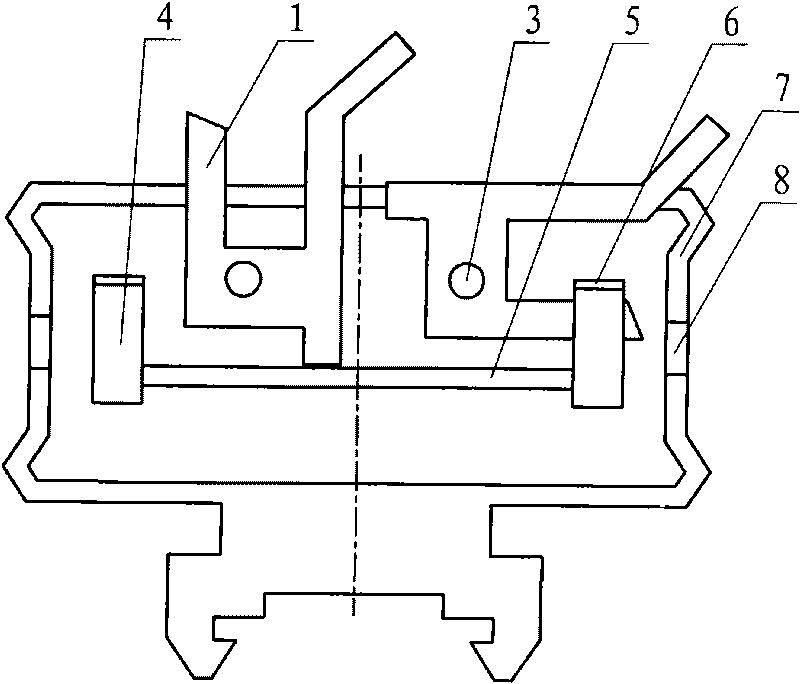

[0018] This high-efficiency broken wire terminal is made of two wire holes 8 symmetrically made in the middle of the housing 2 and the two side walls of the housing. The innovation of the present invention lies in that a V-shaped blade 4 is arranged in parallel beside the two wire holes, and the two V-shaped blades are installed in the housing. Its specific installation structure is: the upper ends of the two V-shaped blades are all shaped with outward flanges 6, and the front end surface 9 and the rear end surface 7 of the housing are formed with installation grooves relative to the positions of the outward flanges, and the outward flanges It can be clamped in the installation groove to realize the fixed installation of the V-shaped blade. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap