Calibration method, calibration device, and calibration system having the device

A calibration method and camera system technology, which can be used in measuring devices, stereo systems, TV system components, etc., can solve problems such as damaged symmetry, inability to detect feature points, and difficulty in implementing high-precision calibration to achieve high precision The effect of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

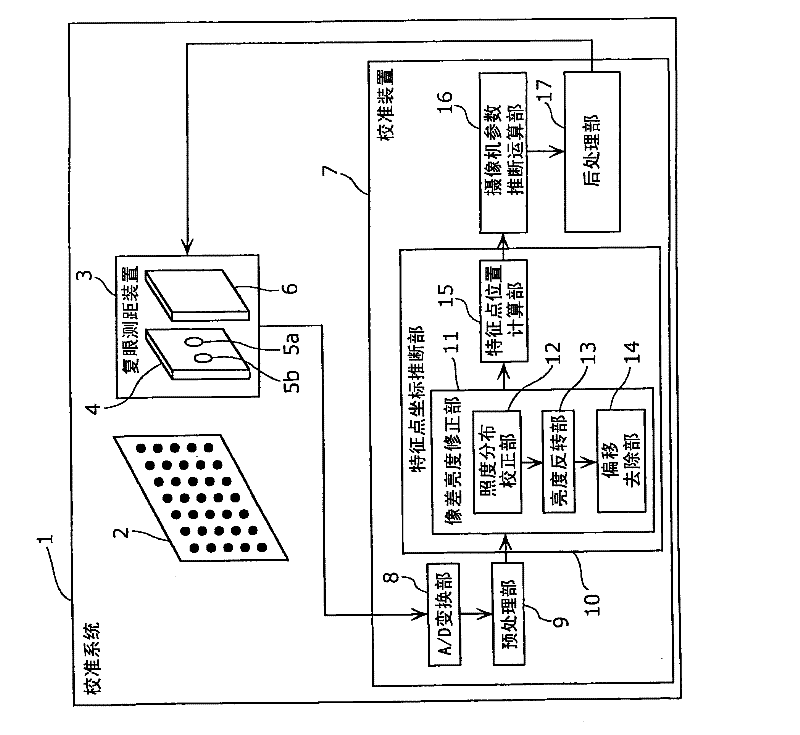

[0171] figure 1 It is a figure which shows the structure of the calibration system which concerns on this embodiment. As shown, the calibration system 1 has a reference figure 2 , compound eye ranging device 3 and calibration device 7. Hereinafter, each component and the overall processing flow of the calibration system 1 will be briefly described.

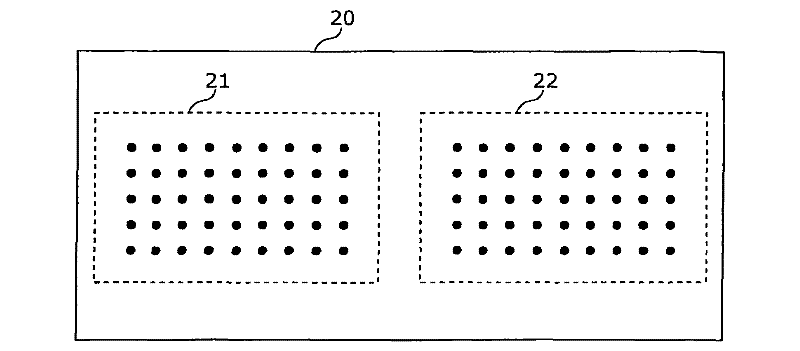

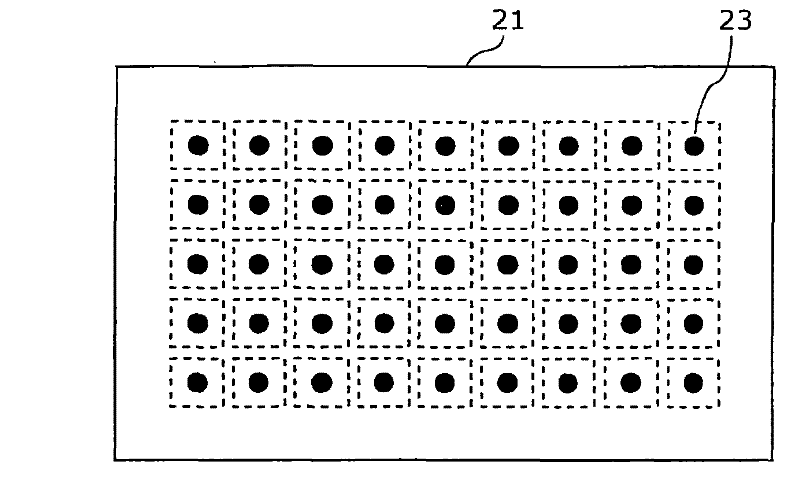

[0172] benchmark figure 2 It is a figure which draws the bead pattern of a black substantially circular element on a white background (white background) with a known size. Here, the bead pattern refers to a geometric pattern in which a plurality of elements forming a substantially circular shape are arranged. Additionally, the benchmark figure 2 The approximate center of gravity position (or approximate center position) of each element of , is assumed to be an actual feature point position, and the arrangement position of the feature point position is assumed to be known (produced with a known size). Furthermore, the app...

Embodiment approach 2

[0245] Next, Embodiment 2 of the present invention will be described with reference to the drawings.

[0246] Figure 9 It is a figure which shows the structure of the calibration system concerning this embodiment. And, with figure 1 Parts with the same numbers are subjected to the same processing as that in Embodiment 1, so description thereof will be omitted.

[0247] In addition, the calibration system 31 of this embodiment is different from the calibration system 1 of the embodiment in that the color matching of the reference chart 30 and the absence of the brightness inversion unit 13 in the calibration device 32, and other components and functions are the same as those of the first embodiment. Calibration system 1 is the same.

[0248] The reference diagram 30 is a diagram in which a bead pattern of white substantially circular elements is drawn on a black background (background black). That is, in the reference map 30 , the color of each element is a grayscale that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com