Width corrugated board production line

A corrugated board and production line technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of reduced production efficiency, low production efficiency, and corrugated boards can only be spliced, and achieve reliable quality, low production efficiency, and overall Quality and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

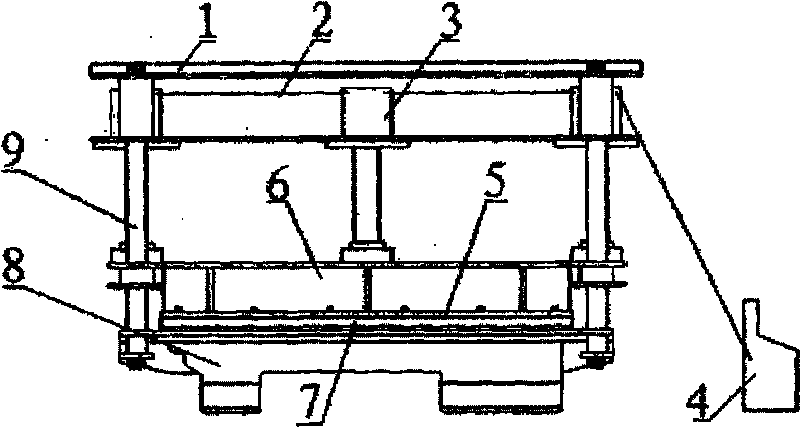

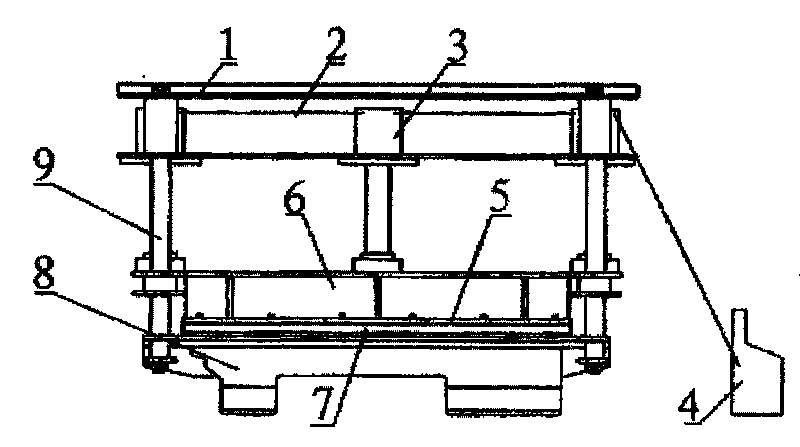

[0015] Example figure 1 As shown, examples such as figure 1 As shown, this wide corrugated board production line is composed of a plate rolling mechanism, a power mechanism, a control mechanism 4 and a support 1. The support 1 is connected to the connecting frame 6 through the sliding shafts 9 at both ends, and the sliding shafts 9 of the hydraulic cylinders 3 on both sides are connected to each other. A guide rod is fixed; there is a crossbeam on the top of the support 1, and there are four guide columns under the beam; the four guide columns of the support 1 are slidingly connected with the guide rod; the workbench 8 is connected to the base and below the connecting frame 6; the power mechanism is independent The hydraulic system is controlled by a separate hydraulic pump station control mechanism 4; the power mechanism is composed of three hydraulic cylinders 3 connected in parallel through hydraulic pipelines 2, and the cylinder bodies of the three hydraulic cylinders 3 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com