Patents

Literature

115results about How to "Protection needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial cultivation method of hemsley rockvine root

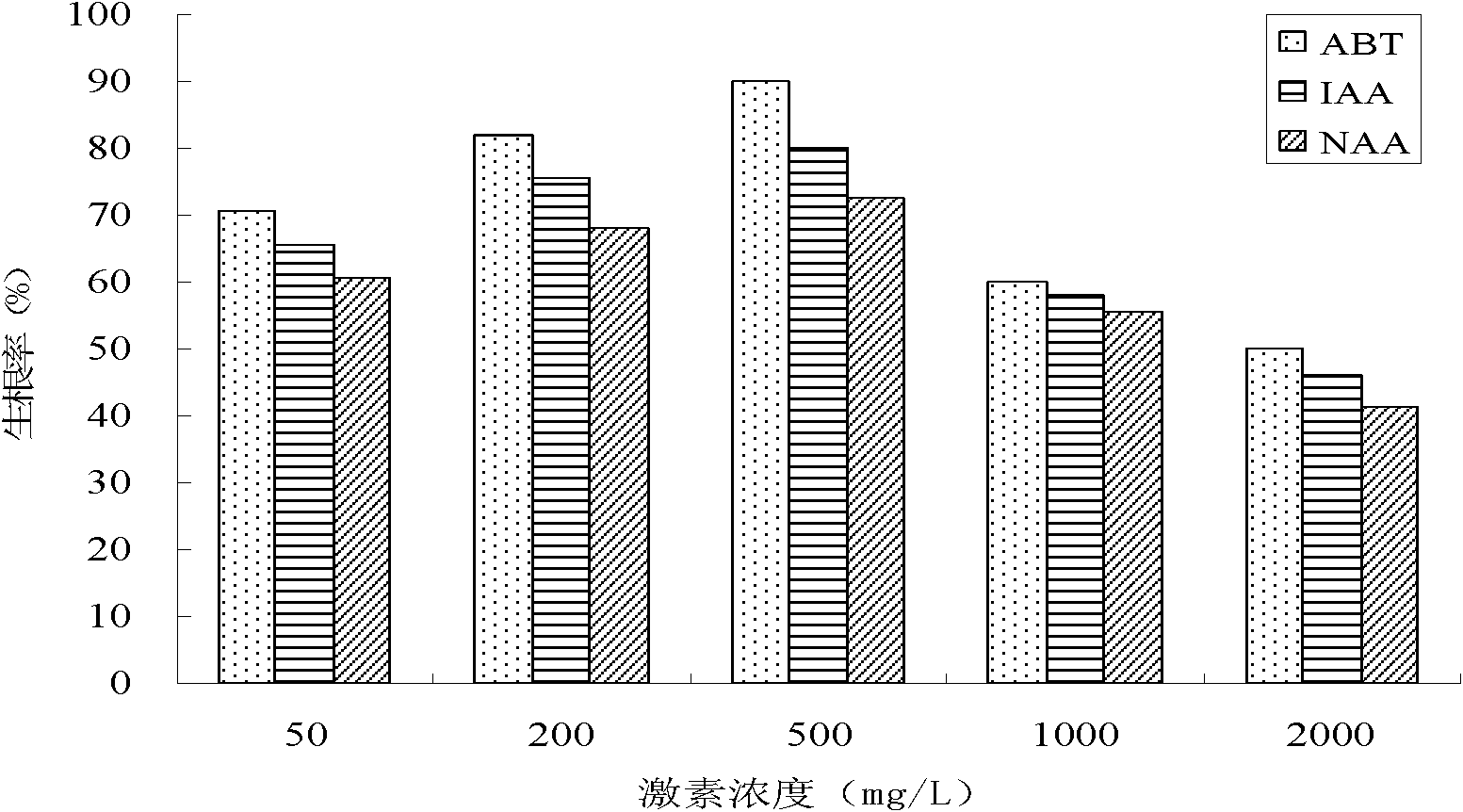

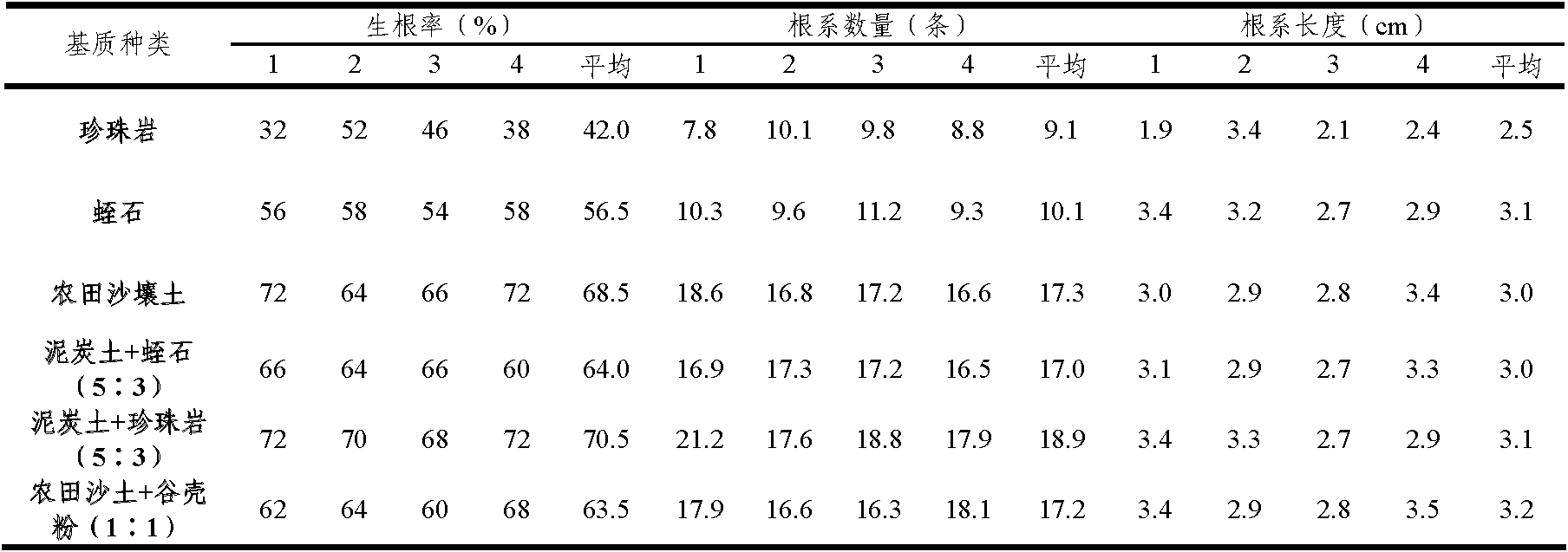

The invention discloses an artificial cultivation method of hemsley rockvine root. The artificial cultivation method comprises the following steps of: 1) selecting an annual or biennial branch which vigorously grows and is well developed and not damaged by diseases or pests, cutting the branch with the length of 4 nodes, keeping 2 leaves on the upper part of the cutting, shearing a lower cut of the cutting into a smooth diagonal plane, and soaking in 500mg / L rooting powder solution; 2) selecting field sandy soil, obliquely cutting the cutting at an angle of 35 to 45 DEG with the ground with the depth of 2 nodes of a lower part, slightly compacting the surrounding substrate and immediately watering after the cutting is completed, keeping the cutting soil humid and keeping shading and ventilation within 15 days after the cutting; and 3) transplanting the cut seedlings to fields in March and April each year, controlling cultivation density, shading by using a sunshade screen in the cultivation period, and applying a calcium fertilizer after 15 days of transplantation. By the technical scheme, the hemsley rockvine root is successfully bred and cultivated, so that a wild hemsley rockvine root resource is protected, artificial excessive collection and digging are avoided, and the requirement of clinical and scientific research medication can be met.

Owner:ZHEJIANG ACAD OF TRADITIONAL CHINESE MEDICINE

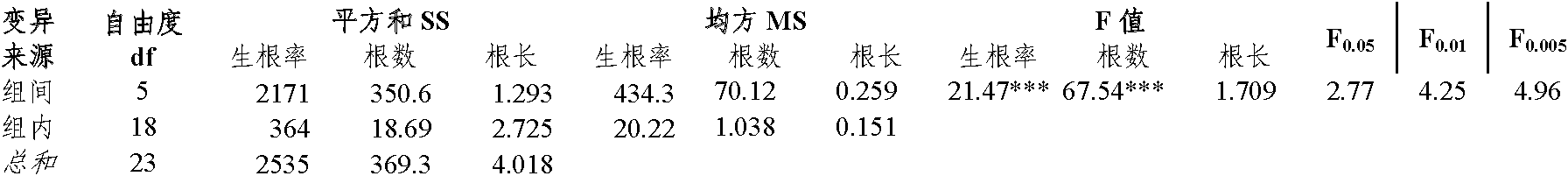

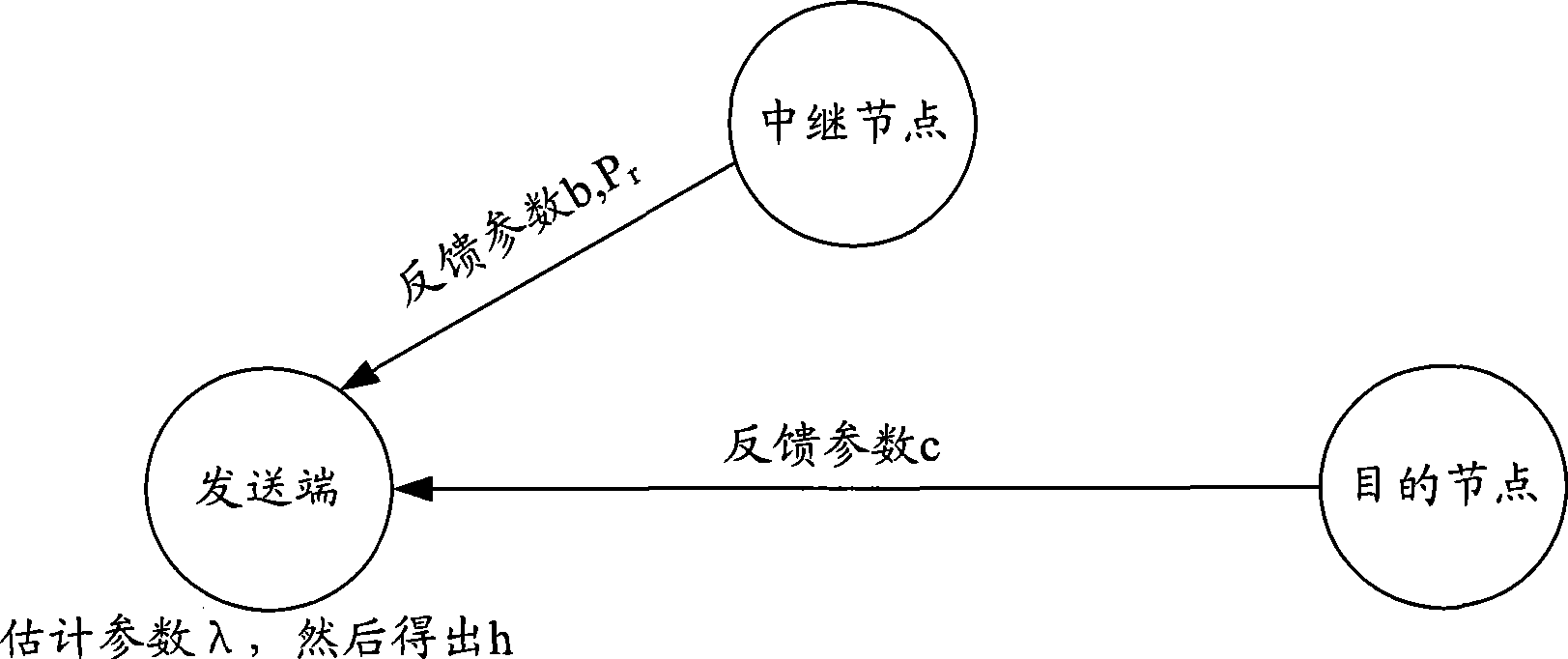

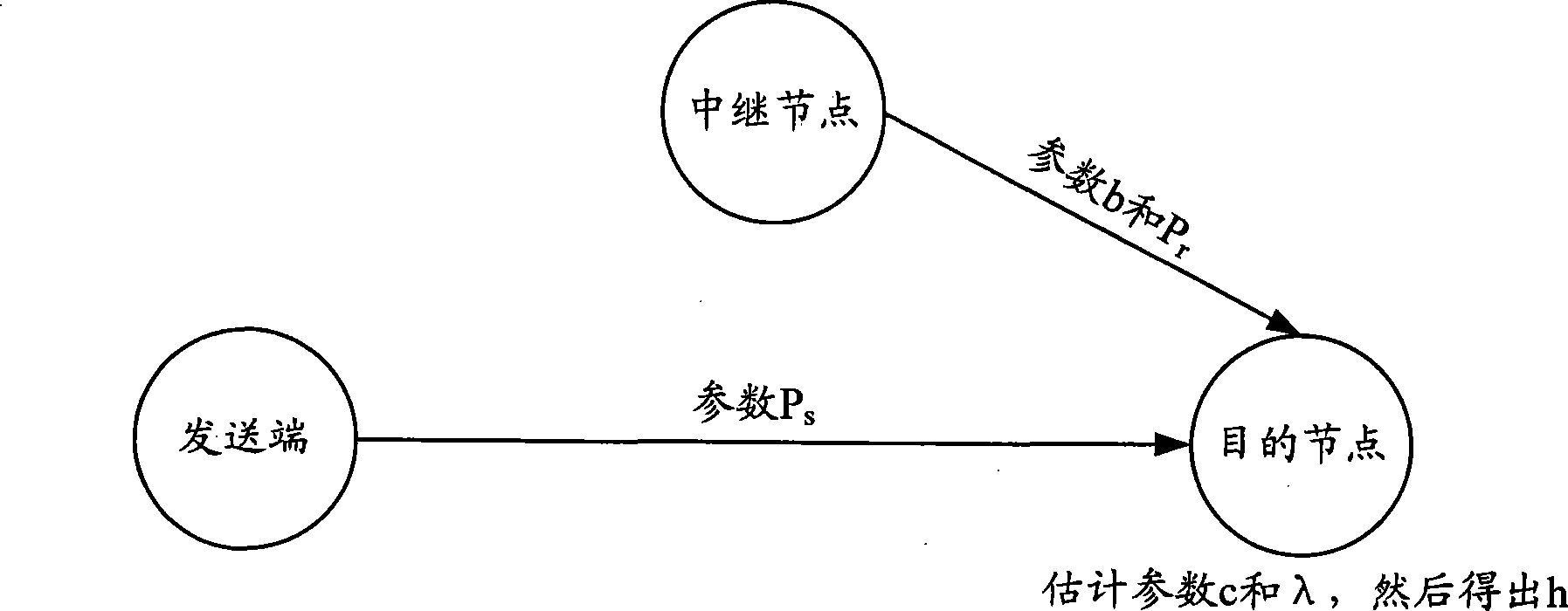

Multi-service mixed transmission implementing method in OFDM cooperation/relay system

InactiveCN101383775AIncrease throughput and transfer rateImprove spectral efficiency and other related system performanceNetwork traffic/resource managementActive radio relay systemsEmbedded systemIteration process

The invention provides a method for realizing multi-service hybrid transmission in orthogonal frequency division multiplexing OFDM synergy / relay system. The method comprises the following steps: firstly, the quality of an equivalent link is collectively estimated according to a mathematical model, then a corresponding feedback mechanism is adopted to obtain correlative parameters which are necessary for collectively estimating the quality of the link, and then on the basis of the link estimating method, aiming at the two different application scenes in the OFDM synergy / relay system: the point-to-point single user and the point-to-multipoint multiuser , and the respective methods for realizing the multi-service hybrid transmissions are put forwards. The method of the invention can effectively ensure the Qos demand of all services, improve the total throughput and the transmission speed of the system, and improve the total spectrum effectiveness and other systematical functions of the whole system. In addition, the operational procedure of the invention is simple and convenient, and is easy to implement, the whole operational process dispenses with highly complex search and cyclic iteration process, the complexities of the whole operational process are all linear complexities, and the demand of real-time data service transmission in future wireless communication can be completely met.

Owner:BEIJING UNIV OF POSTS & TELECOMM

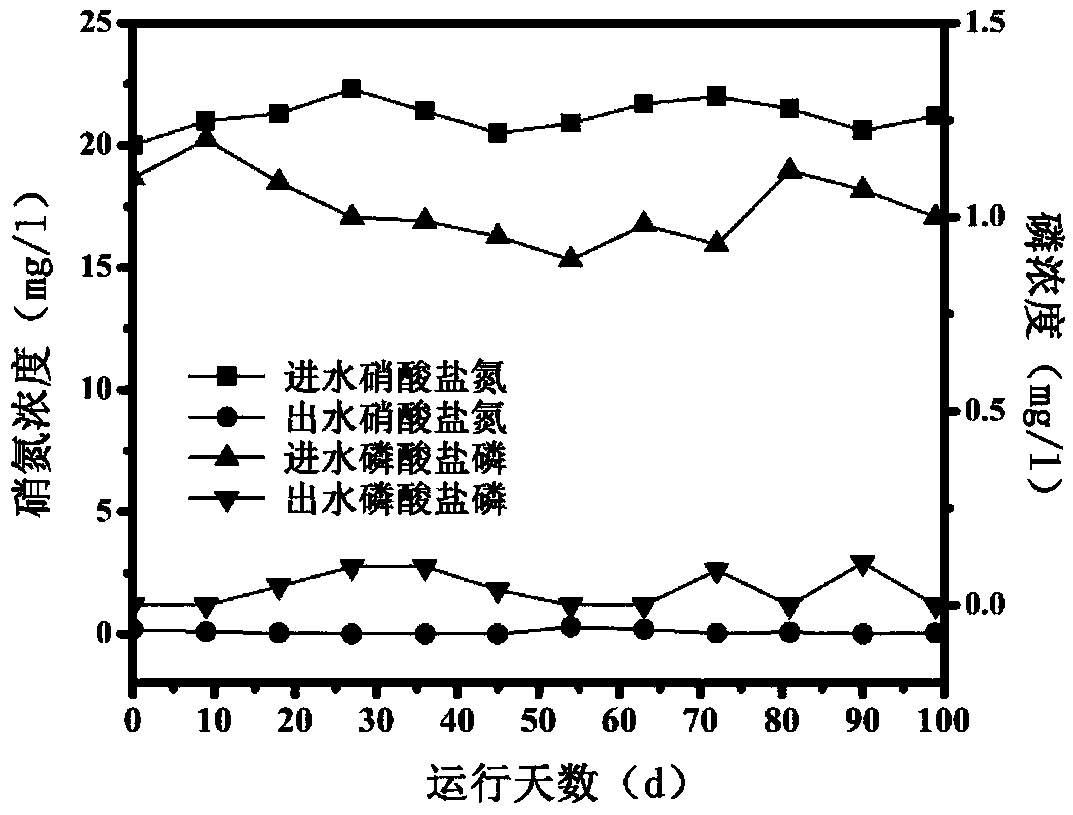

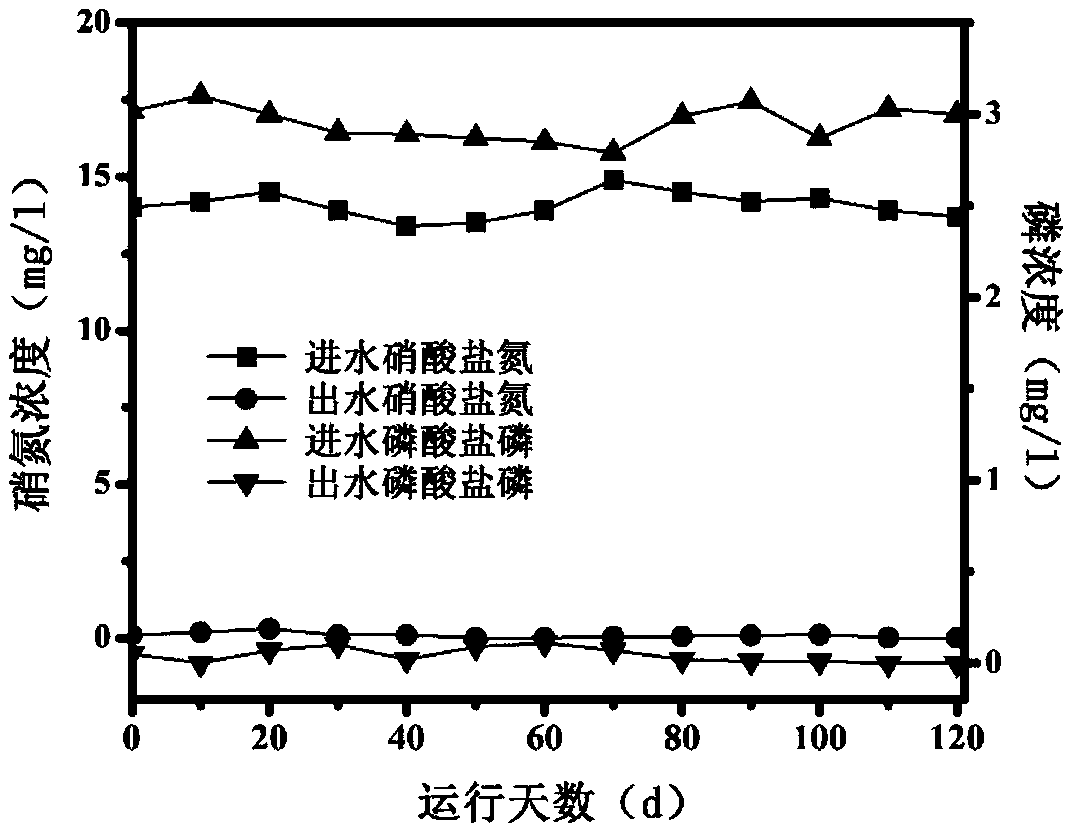

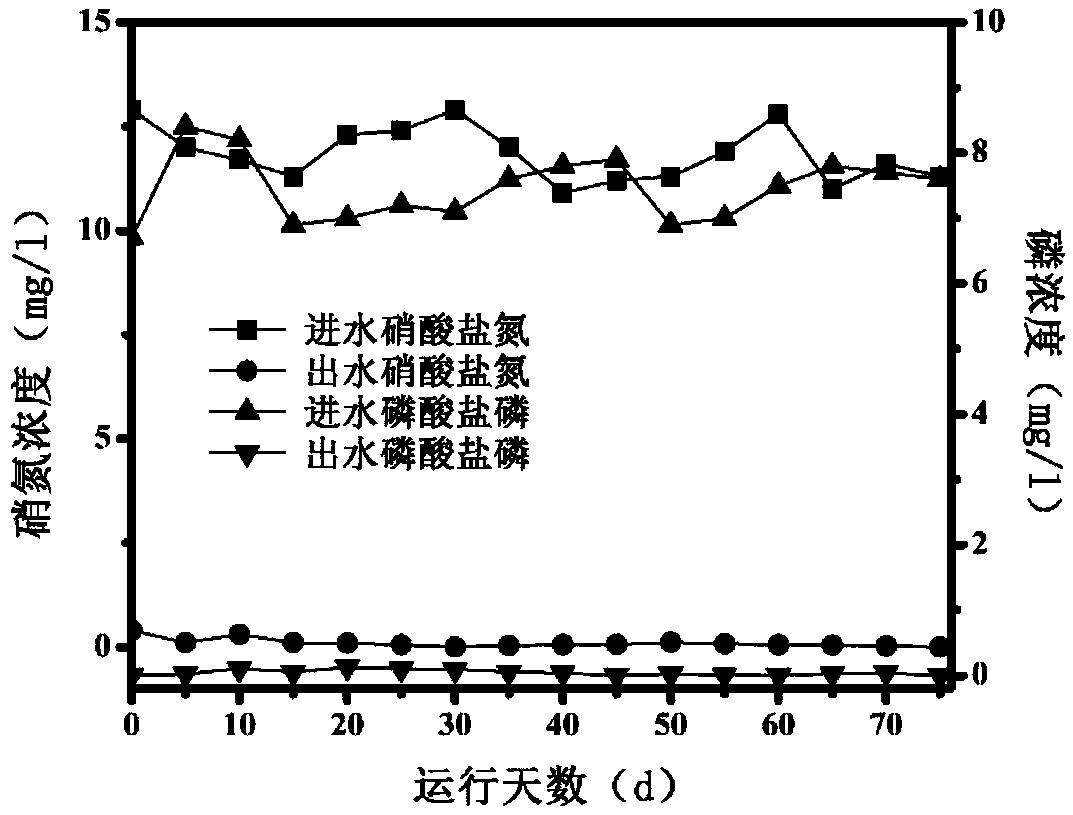

Coupling filler autotrophic denitrification biofilter and application

ActiveCN109052641ADifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiofilmSewage

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

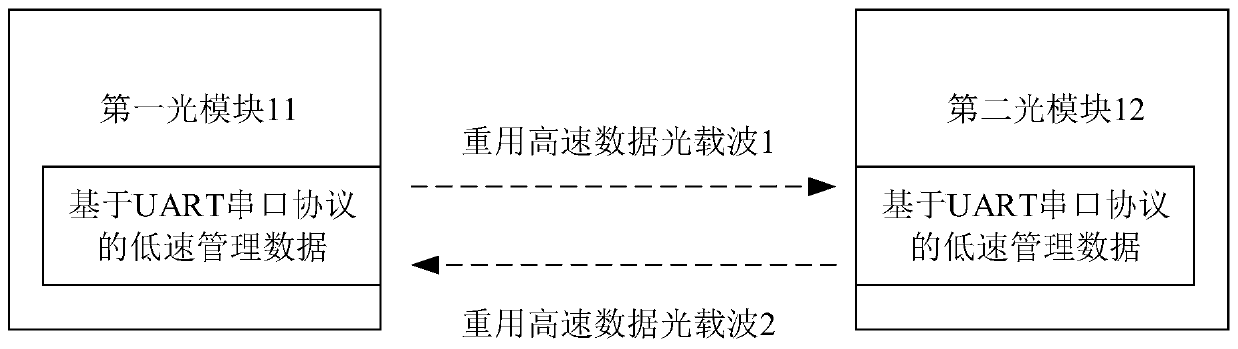

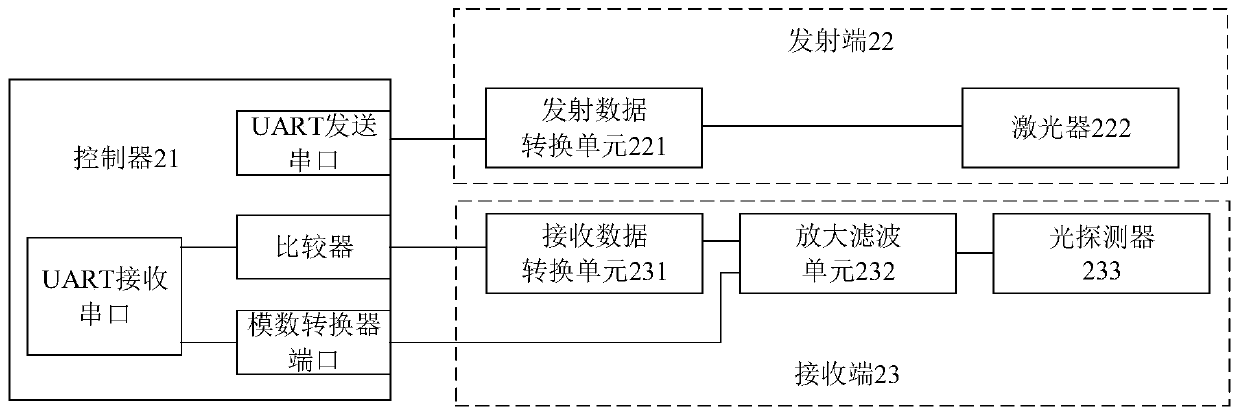

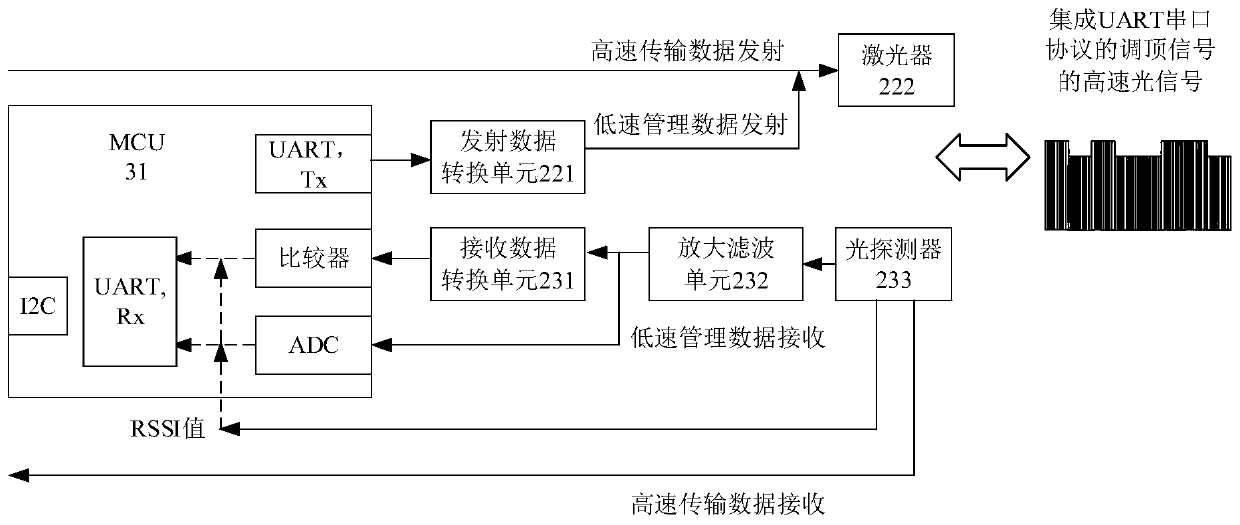

Optical module signal processing method and device and optical module

ActiveCN111371498AImprove communication efficiencyImprove communication qualityElectromagnetic transmittersElectromagnetic transceiversData transformationOptical communication

The invention provides an optical module signal processing method and device, and an optical module, and relates to the technical field of optical communication, and the method comprises the steps: obtaining the signal-to-noise ratio information of a first low-speed top adjustment signal when the condition that an optical detector of the optical module receives the first low-speed top adjustment signal with first low-speed management data is monitored; determining a target demodulation mode of the first low-speed top adjustment signal according to the signal-to-noise ratio information, whereinthe target demodulation mode comprises a first demodulation mode based on a received data conversion unit and a comparator and a second demodulation mode based on an analog-to-digital converter; anddemodulating the first low-speed top adjustment signal according to the target demodulation mode to obtain first low-speed management data. In this way, for different receiving scenes, the demodulation mode of the first low-speed management data is flexibly selected based on the signal-to-noise ratio information of the first low-speed top adjustment signal, the communication efficiency and the communication quality between the optical modules are improved, and therefore the user requirements are met.

Owner:DONGGUAN MENTECH OPTICAL & MAGNETIC CO LTD

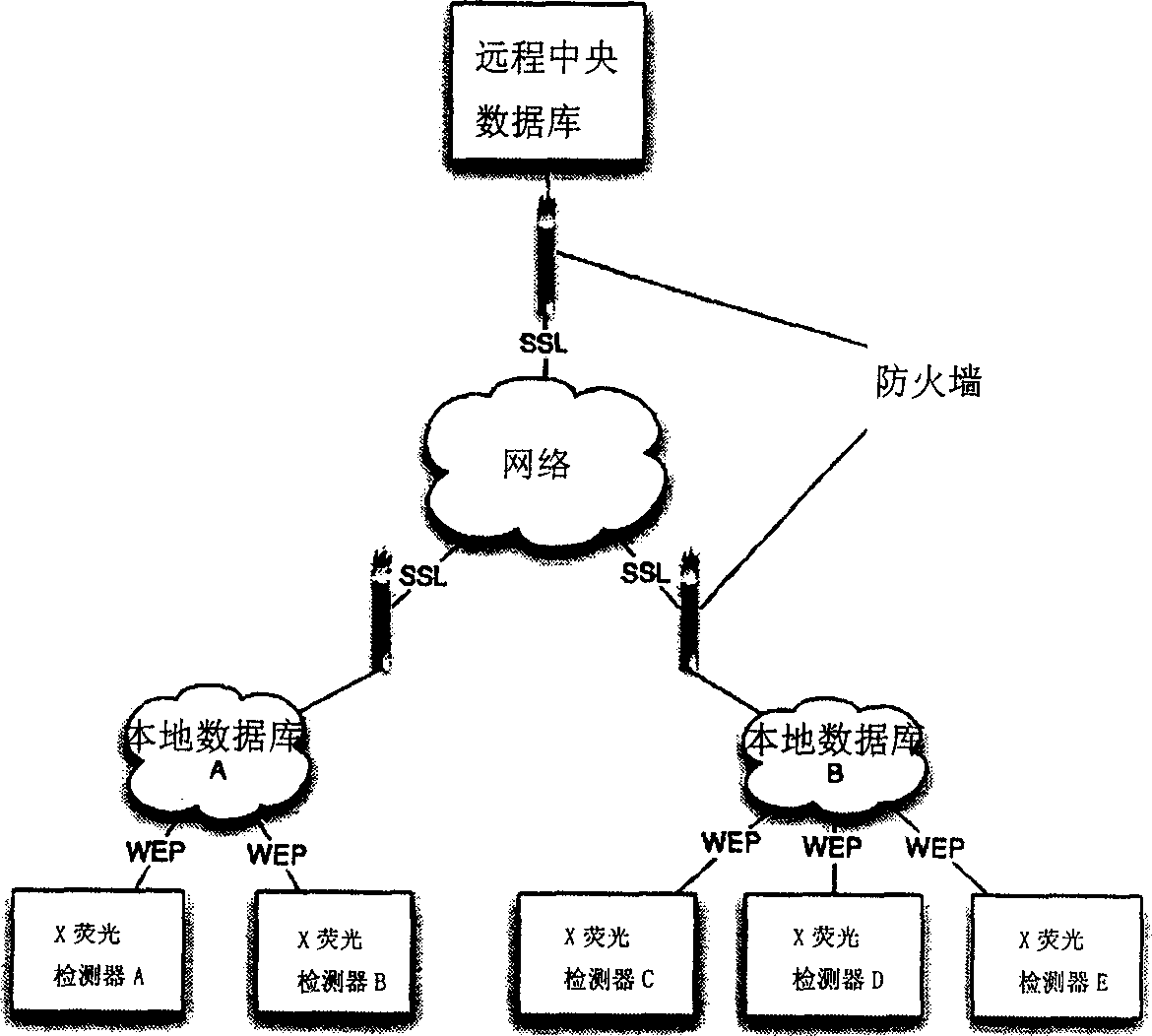

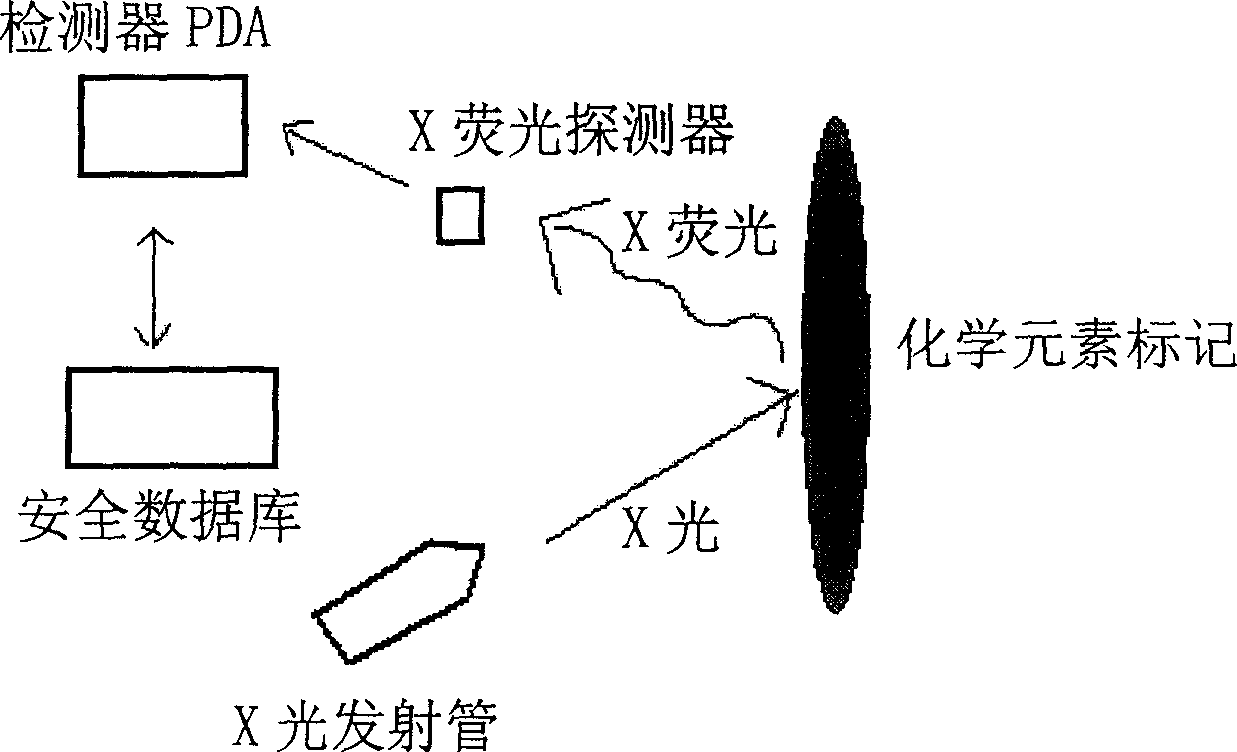

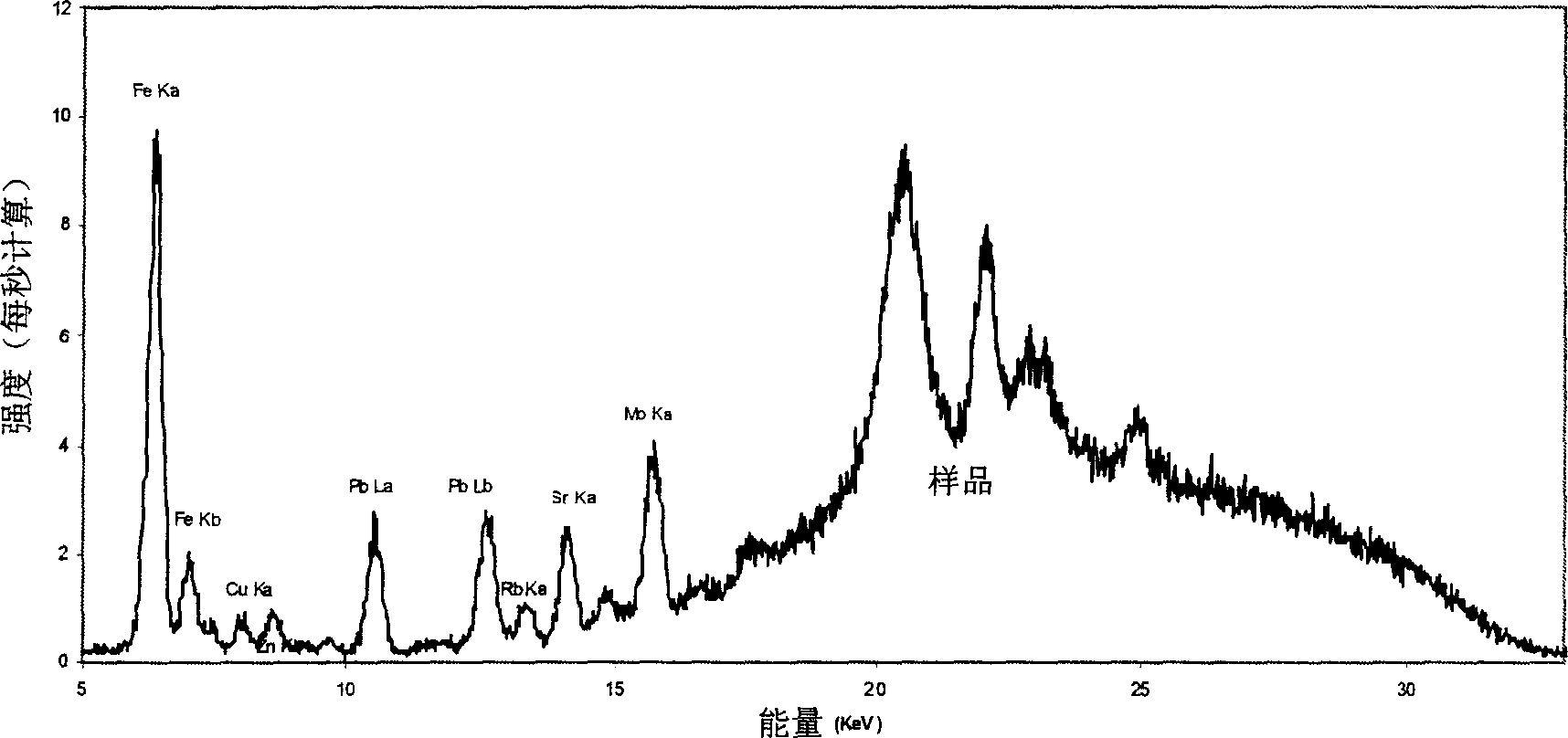

Mark method adopting chemical elements, device thereof and chemical elements marking

InactiveCN1908957AProtect personal safety and healthPrevent Recipe DuplicationDigitally marking record carriersMaterial analysis using wave/particle radiationFluorescenceLight spectrum

The disclosed chemical element labeling method comprises: setting chemical element label included one or more elements with atomic number more than 22 on target, detecting the nominal spectrum data of label by X fluorescence detector to compare with detected data in security database. This invention does not dissolve general organic or inorganic solvent, has well stability, and introduces well detection accuracy without damage to target surface.

Owner:TRUE PROD ID TECH BEIJING

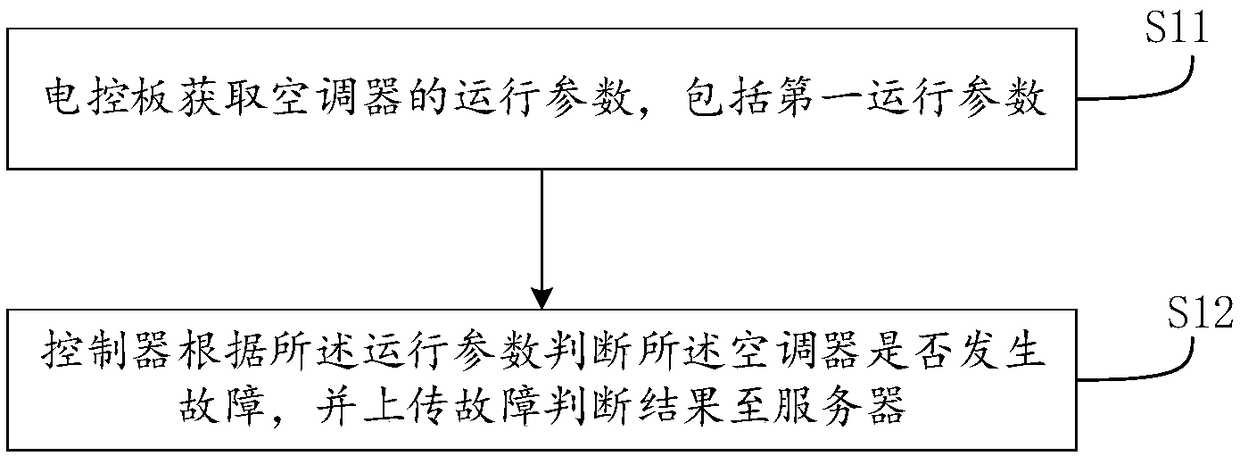

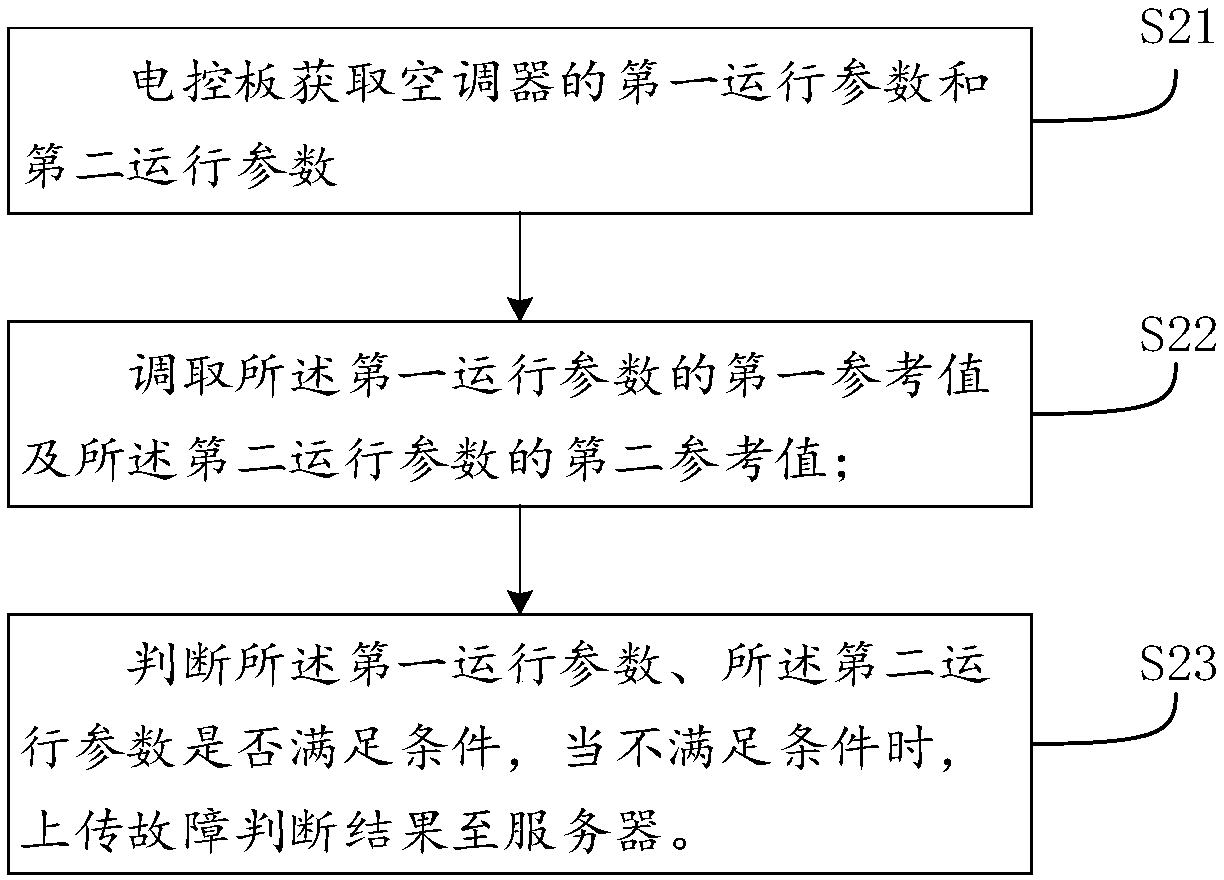

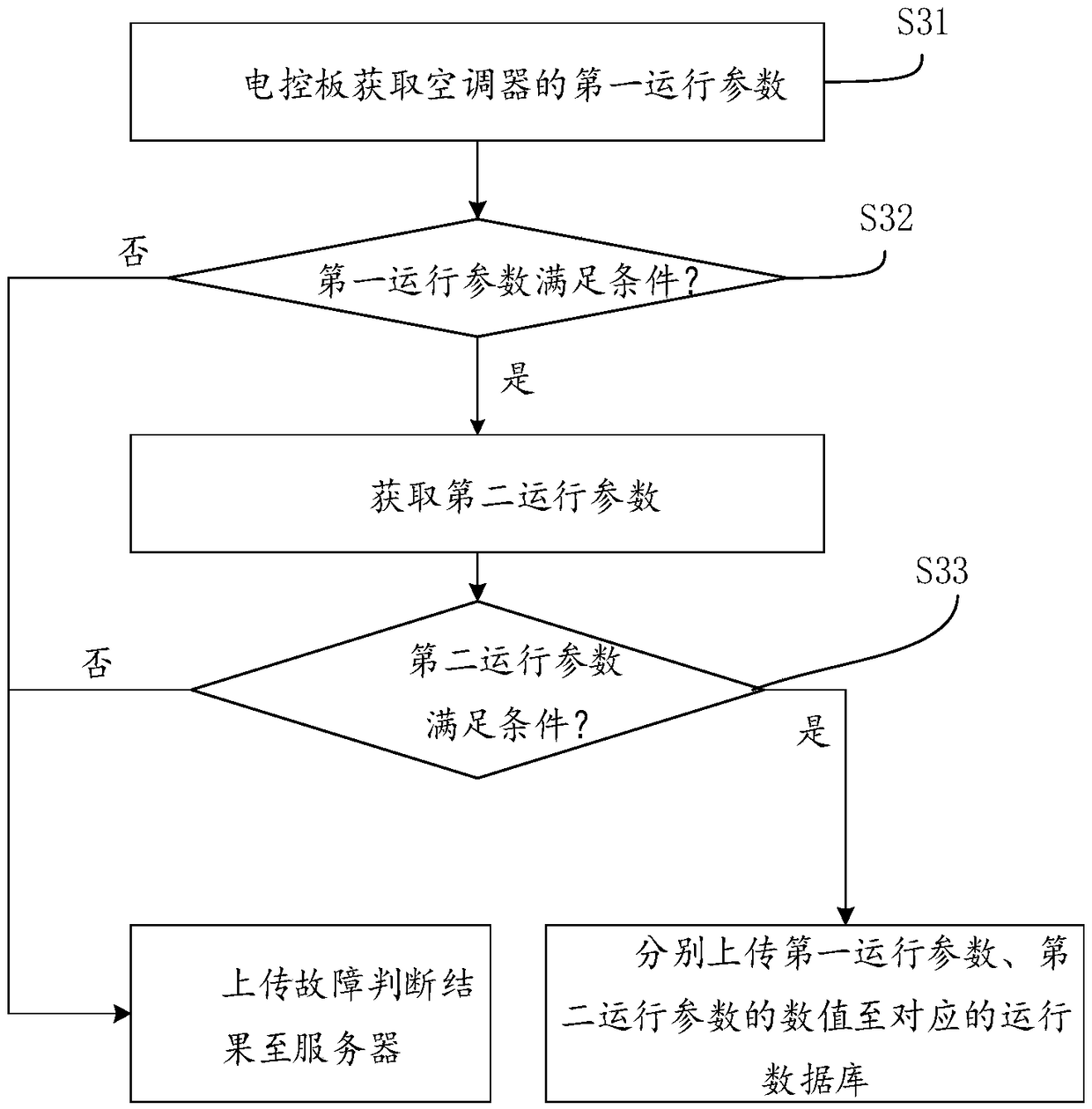

Air conditioner failure pre-diagnosis method and device and air conditioner

InactiveCN109357359AFast and Easy Pre-DiagnosticsProtection needsSpace heating and ventilation safety systemsLighting and heating apparatusService personnelDiagnosis methods

The invention discloses an air conditioner failure pre-diagnosis method and belongs to the technical field of air-conditioning system maintenance. The air conditioner failure pre-diagnosis method comprises the following steps: acquiring the operating parameter of an air conditioner; and judging whether the air conditioner has failure or not according to the operating parameter, and uploading the failure judgement result to a server, wherein the operating parameter comprises a first operating parameter. With adoption of the air conditioner failure pre-diagnosis method, during the operating process of the air conditioner, based on big data and according to the acquired operating parameter, failure pre-diagnosis is carried out on the functional status of the refrigerating / heating system of the air conditioner, and the judgement result is timely pushed to an after-sales service personnel, so that timely and active treatment is realized, pressure detection or refrigerant supplementation iscarried out in advance through door-to-door service, and the user demand is ensured. The invention further discloses an air conditioner failure pre-diagnosis device and the air conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

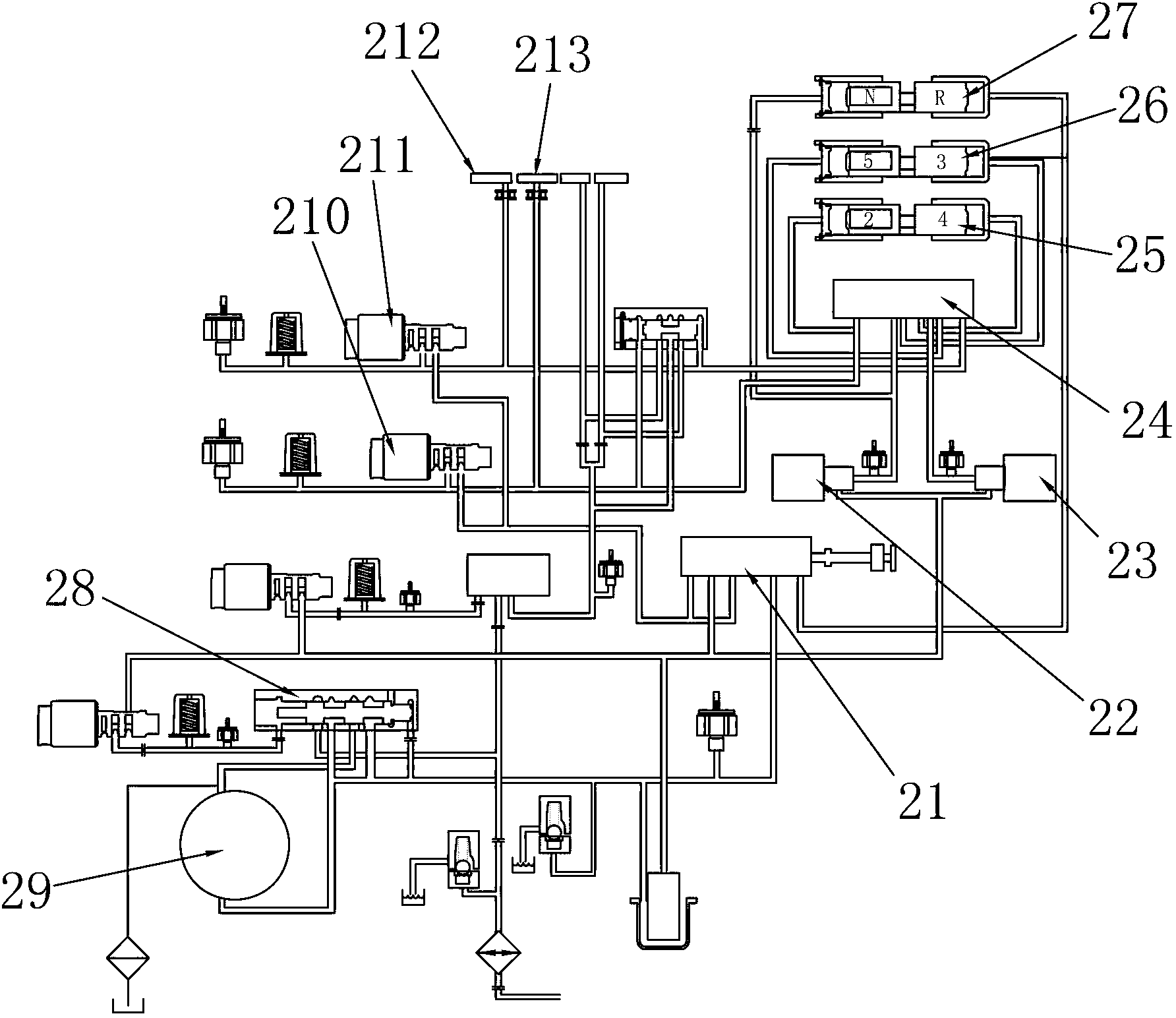

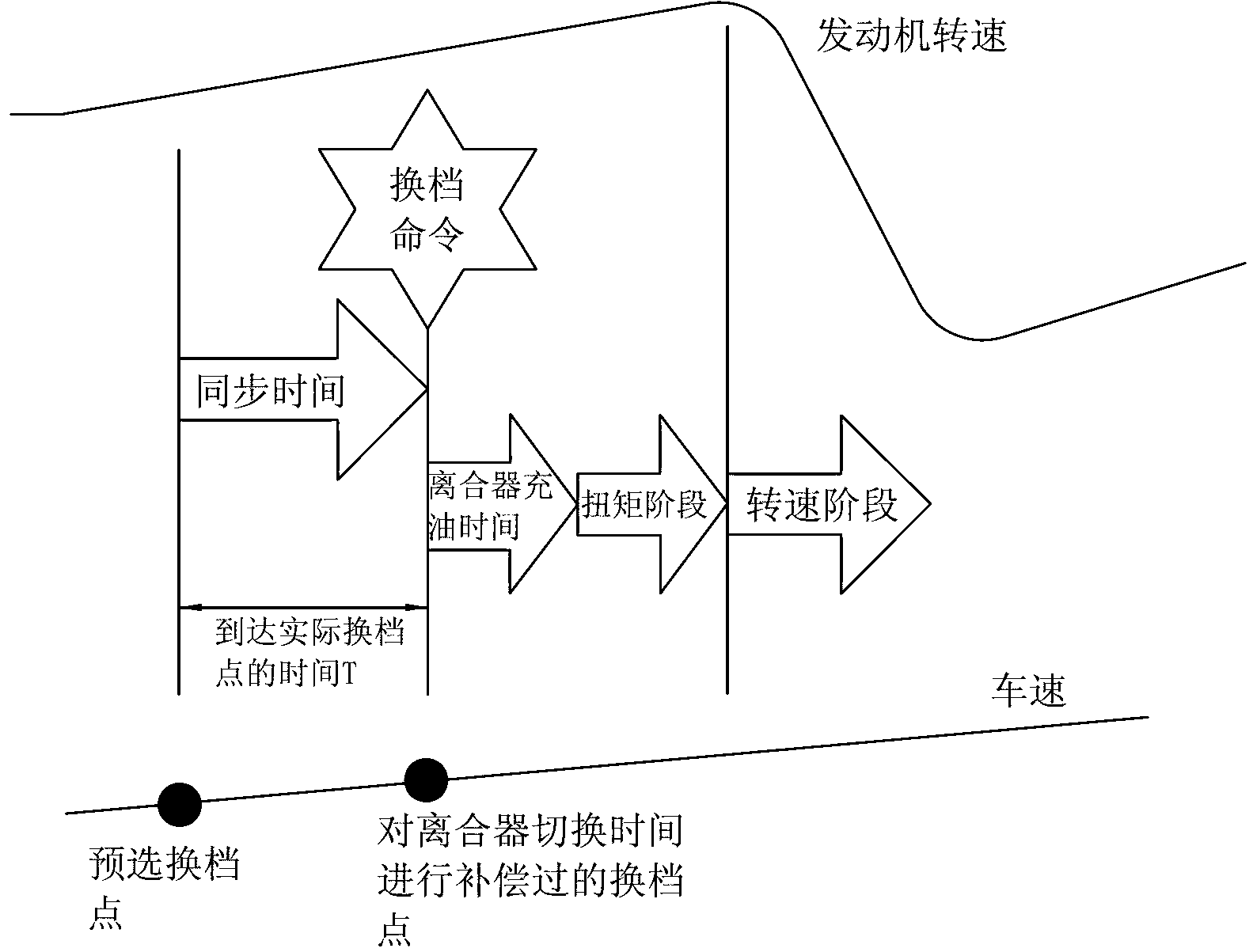

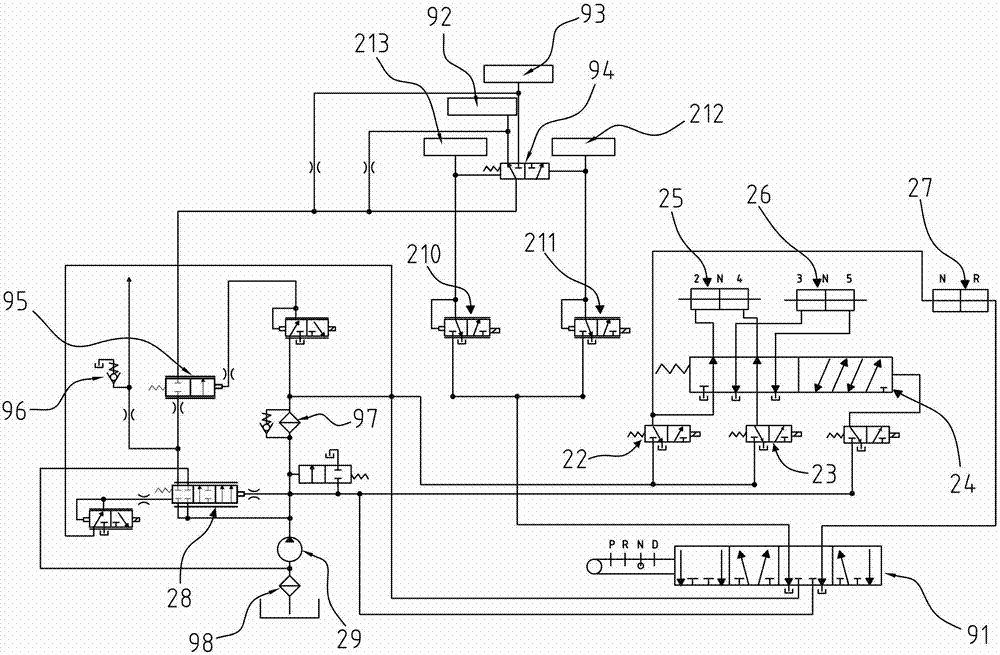

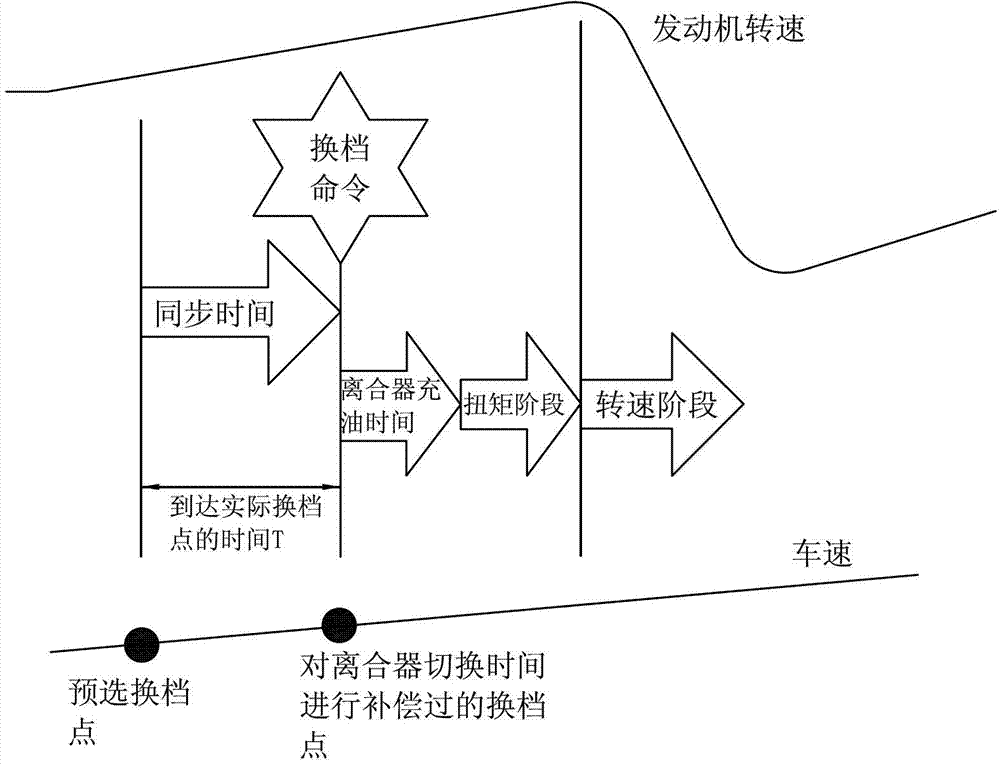

Control method for gear preselection of dual clutch transmission

The invention relates to a control method for gear preselection of a dual clutch transmission and a control method for the dual cultch transmission, in particular to a control method used for gear preselection performed on an unengaged shaft of the dual clutch transmission. The control method aims at guaranteeing economical and dynamic requirements of shift points and drivability and comfortableness of the whole vehicle. The control method mainly includes steps: judging a gear needing to be engaged on a target shaft according to the acceleration of the whole vehicle and a currently running gear; calculating the time T needed for reaching an actual shift point of a preselected gear; determining the time T1 needed for completing engagement of the preselected gear according to the rotating speed of the target shaft; determining the time T2 needed for a synchronizer to totally complete engagement of the preselected gear according to positions of the synchronizer; determining a safe time factor T3 according to T1; and adding T2 and T3, and if the sum is equal to T, ordering the synchronizer to start to execute engagement of the preselected gear.

Owner:CHONGQING TSINGSHAN IND

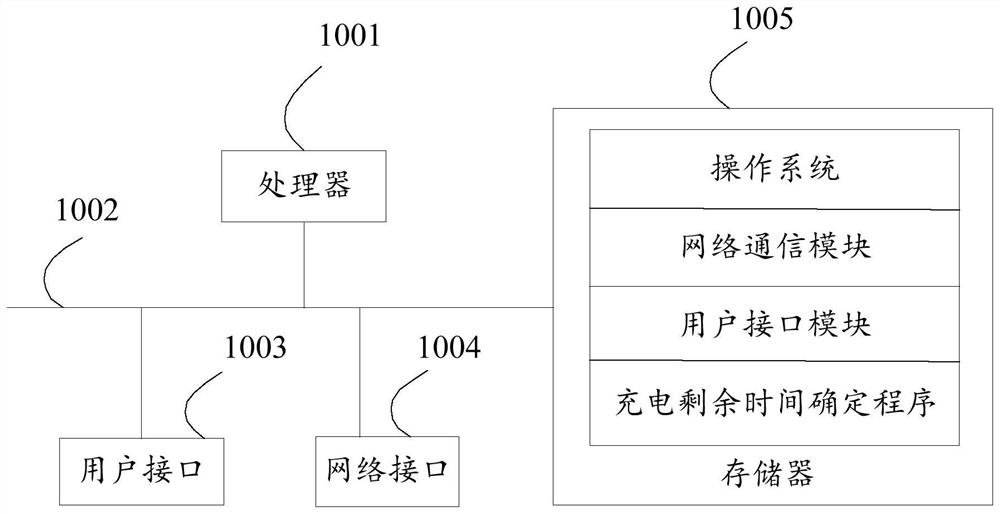

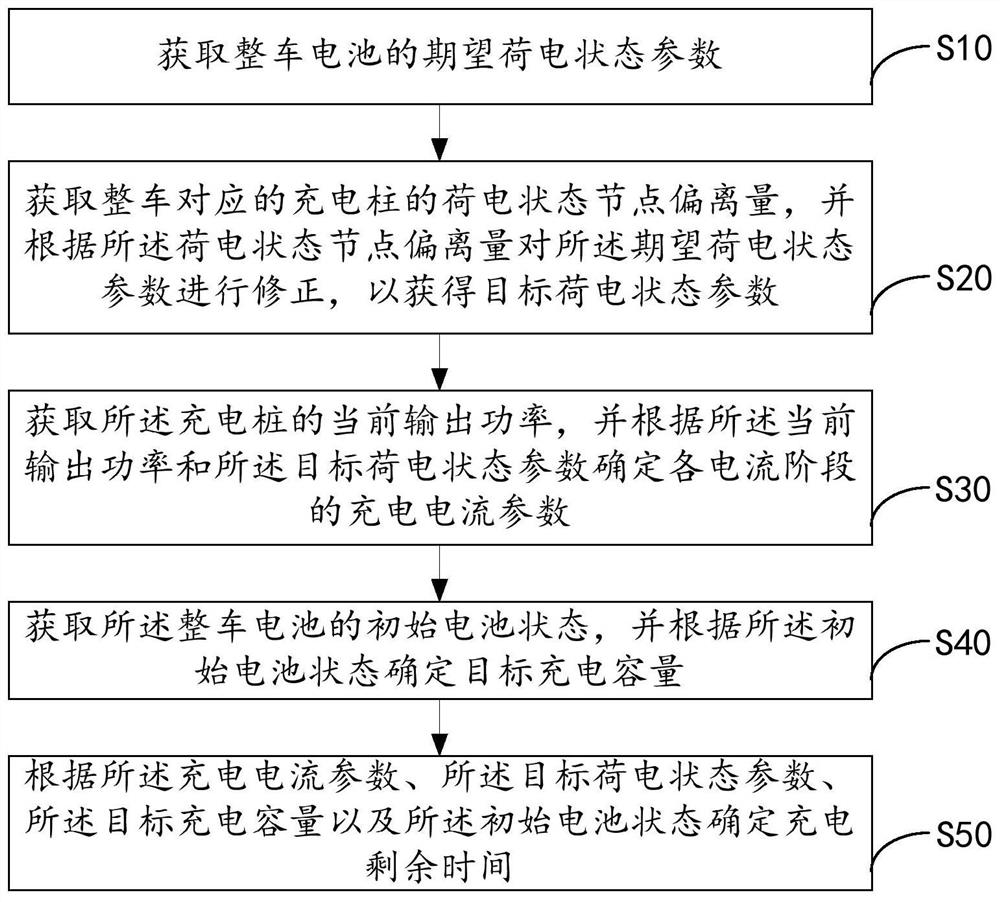

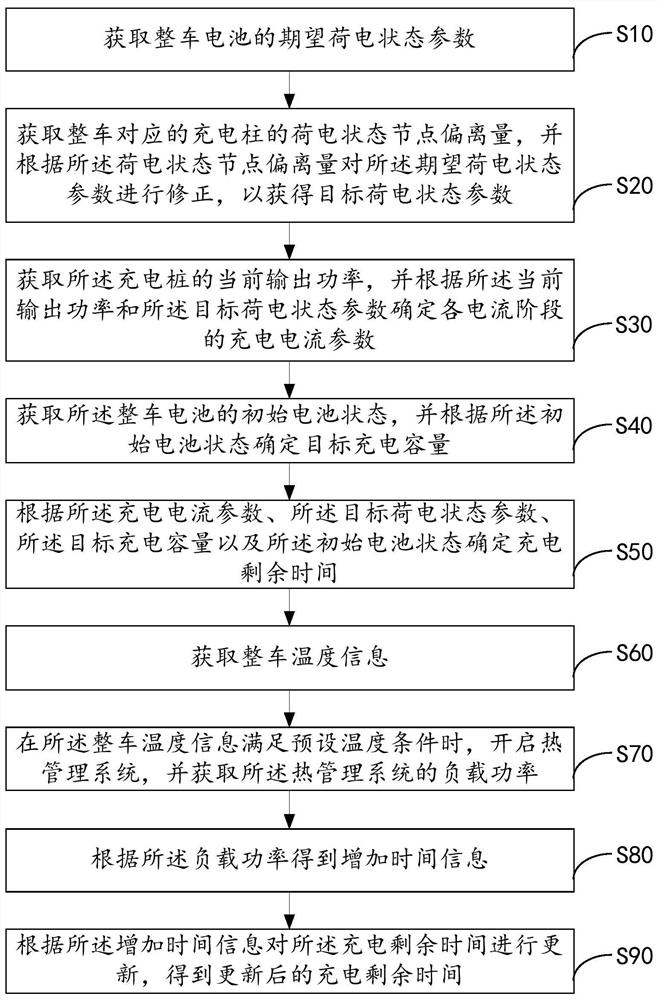

Charging remaining time determination method, equipment and device, and storage medium

ActiveCN111999660AProtection needsImprove satisfactionElectrical testingSecondary cells testingCharge currentElectric current flow

The invention discloses a charging remaining time determination method, equipment and device and a storage medium, and relates to the technical field of vehicles. The charging remaining time determination method comprises the steps of: acquiring expected state-of-charge parameters of a whole vehicle battery; acquiring a state-of-charge node deviation amount of a charging pile corresponding to thewhole vehicle, and correcting the expected state-of-charge parameters according to the state-of-charge node deviation amount to obtain target state-of-charge parameters; acquiring current output powerof the charging pile, and determining charging current parameters of each current stage according to the current output power and the target state-of-charge parameters; acquiring an initial battery state of the whole vehicle battery, and determining a target charging capacity according to the initial battery state; and determining the charging remaining time according to the charging current parameters, the target state-of-charge parameters, the target charging capacity and the initial battery state. According to the charging remaining time determination method, the charging current in different charging current stages is determined according to the actual output power of the charging pile, so that the charging remaining time is accurately determined.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

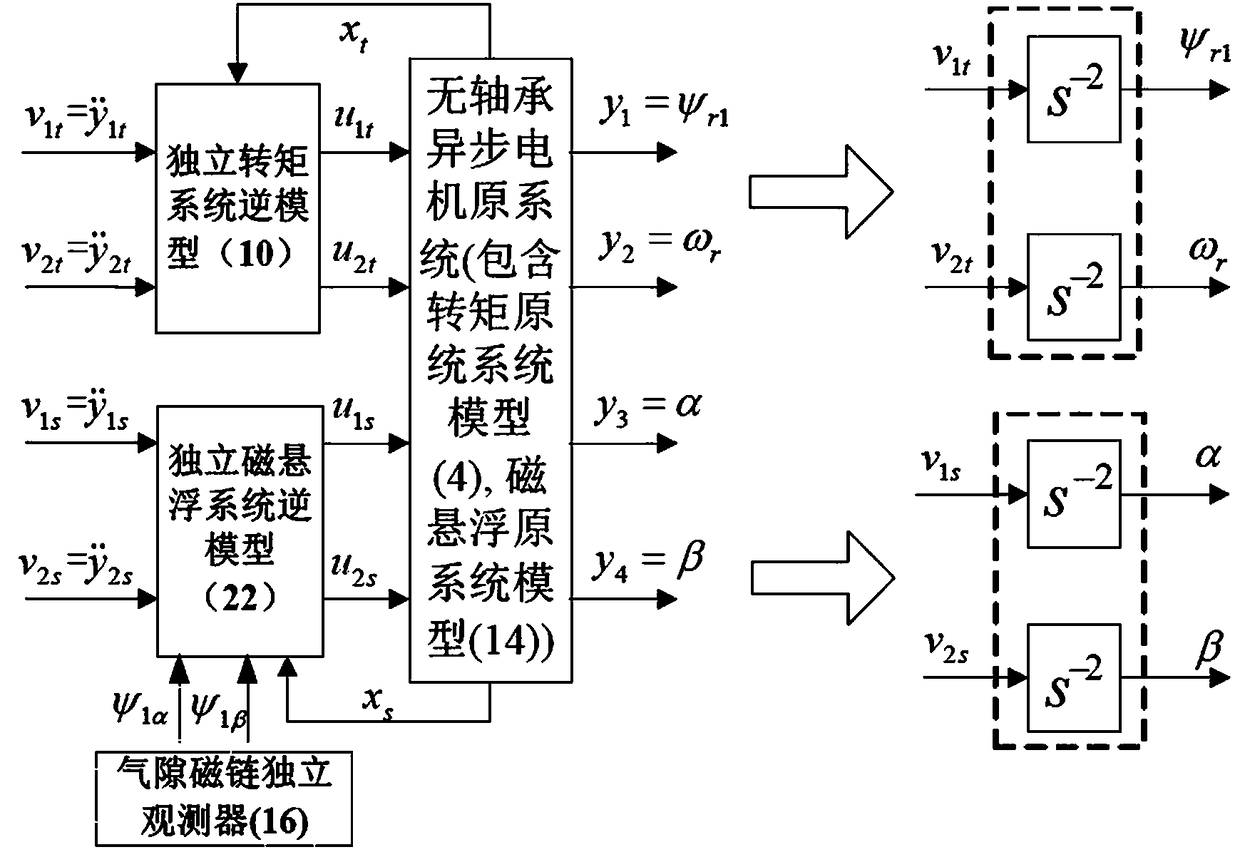

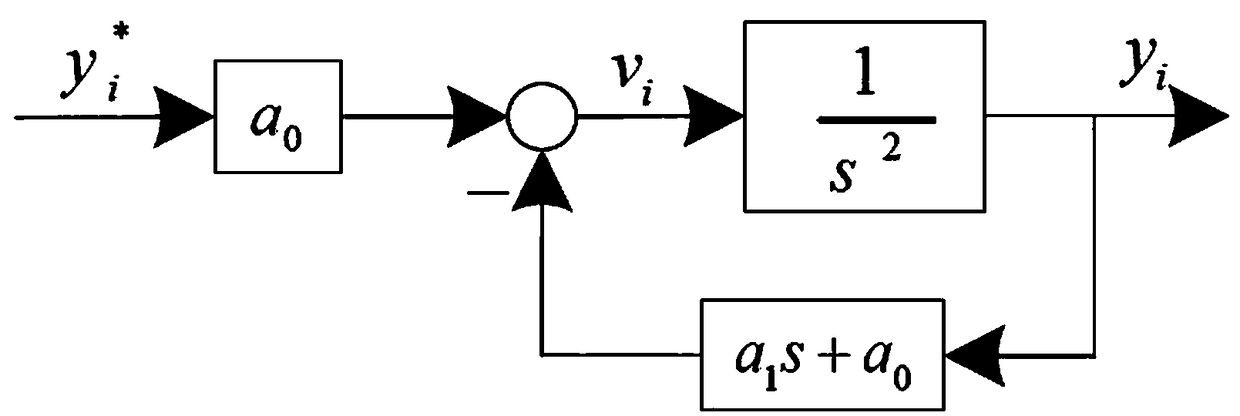

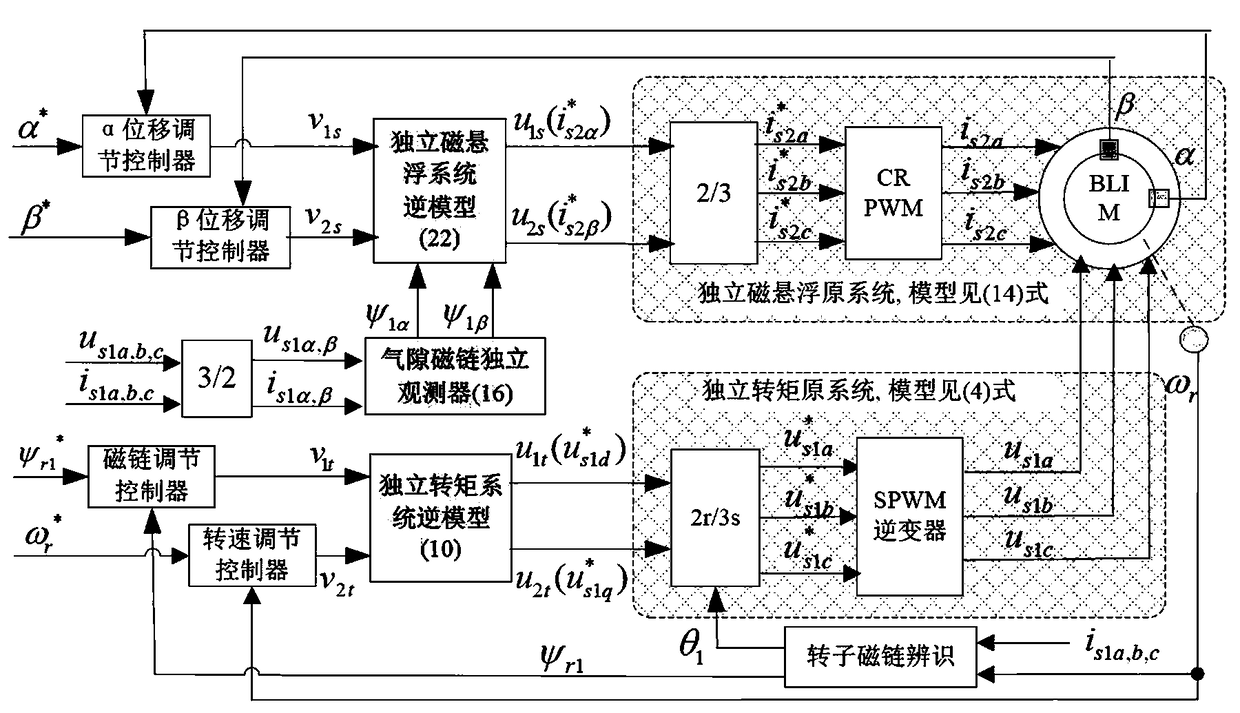

Independent inverse decoupling control system of bearingless induction motor

ActiveCN109217766ASimple structureSimple modelElectronic commutation motor controlAC motor controlInduction motorControl system

Independent inverse decoupling control system of bearingless induction motor, comprises a bearingless induction motor original system, a bearingless induction motor inverse system arranged in front ofthe bearingless induction motor original system, and four regulating controllers arranged in front of the bearingless inverse system. The alpha displacement controller, beta displacement controller,flux linkage controller and rotational speed controller are all constructed by pole placement method. The original system of bearingless induction motor is composed of independent maglev system and independent torque system. The control system is a kind of high-performance maglev decoupling control system with strong real-time performance, It can realize the dynamic decoupling control of bearingless induction motor, simplify the complexity of the system model, avoid the dependence of the inverse model of the magnetic suspension system on the torque system field-oriented mode, and is especiallysuitable for high-speed motor driving applications where the dynamic control performance is high.

Owner:HENAN UNIV OF SCI & TECH

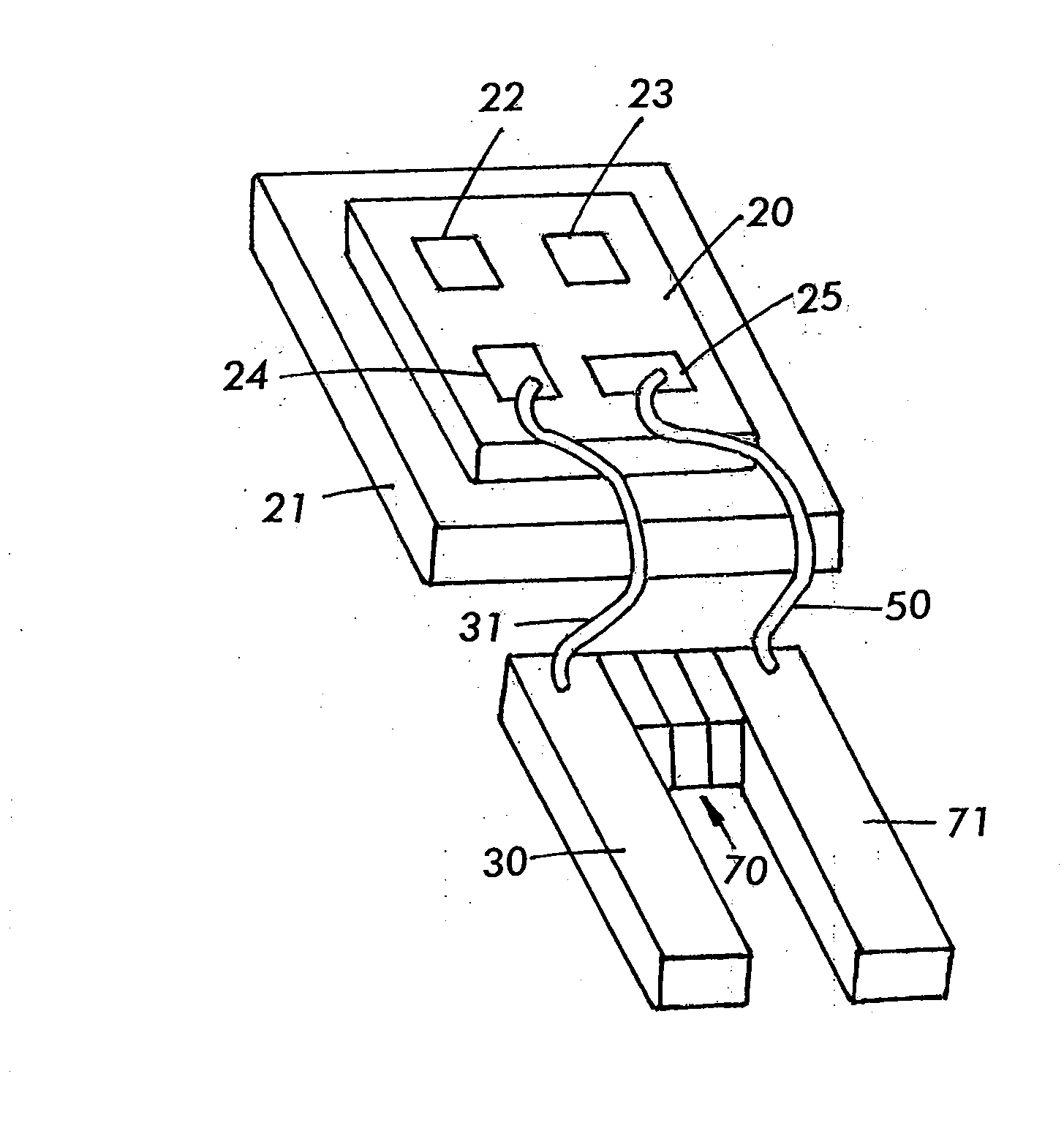

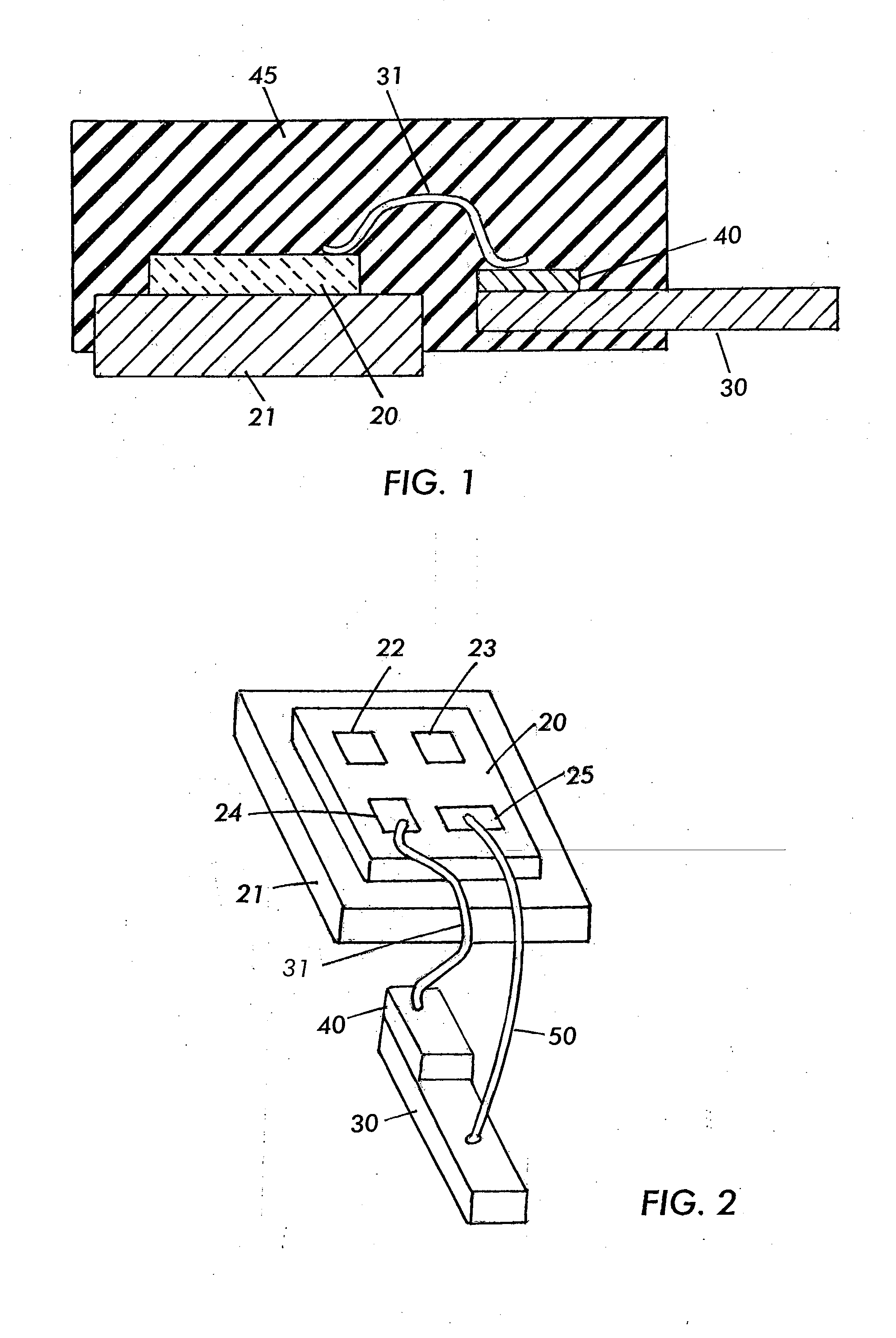

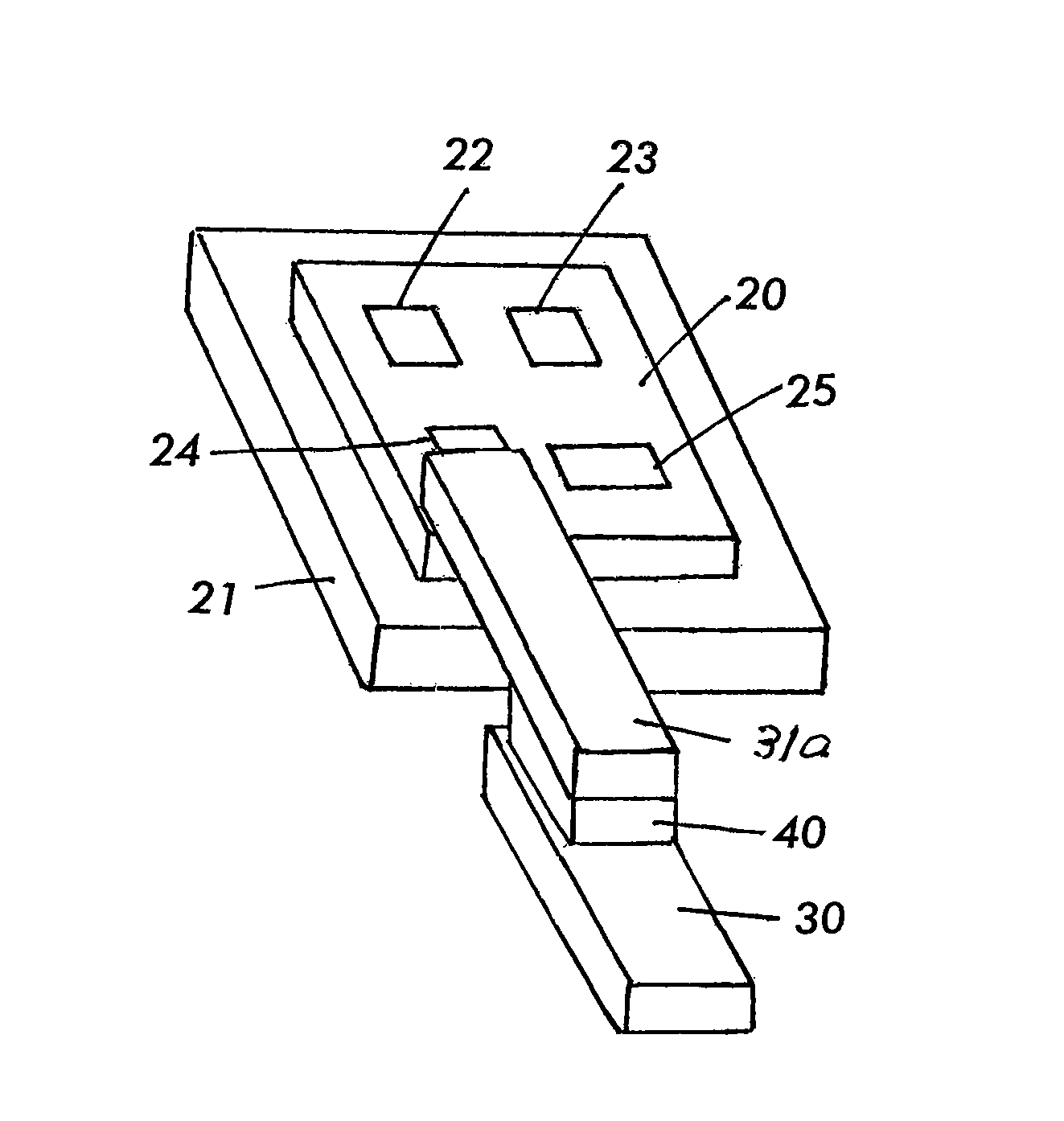

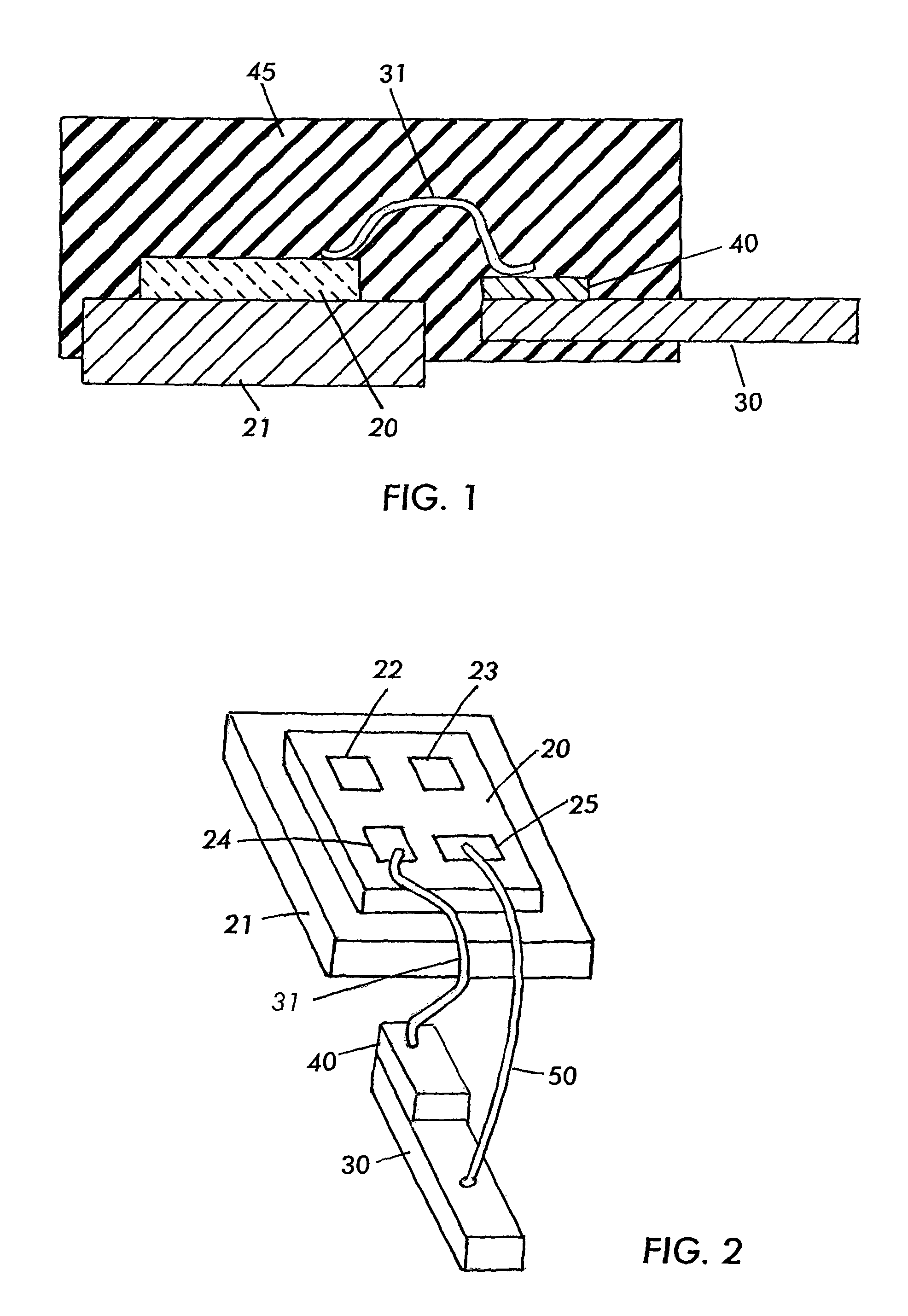

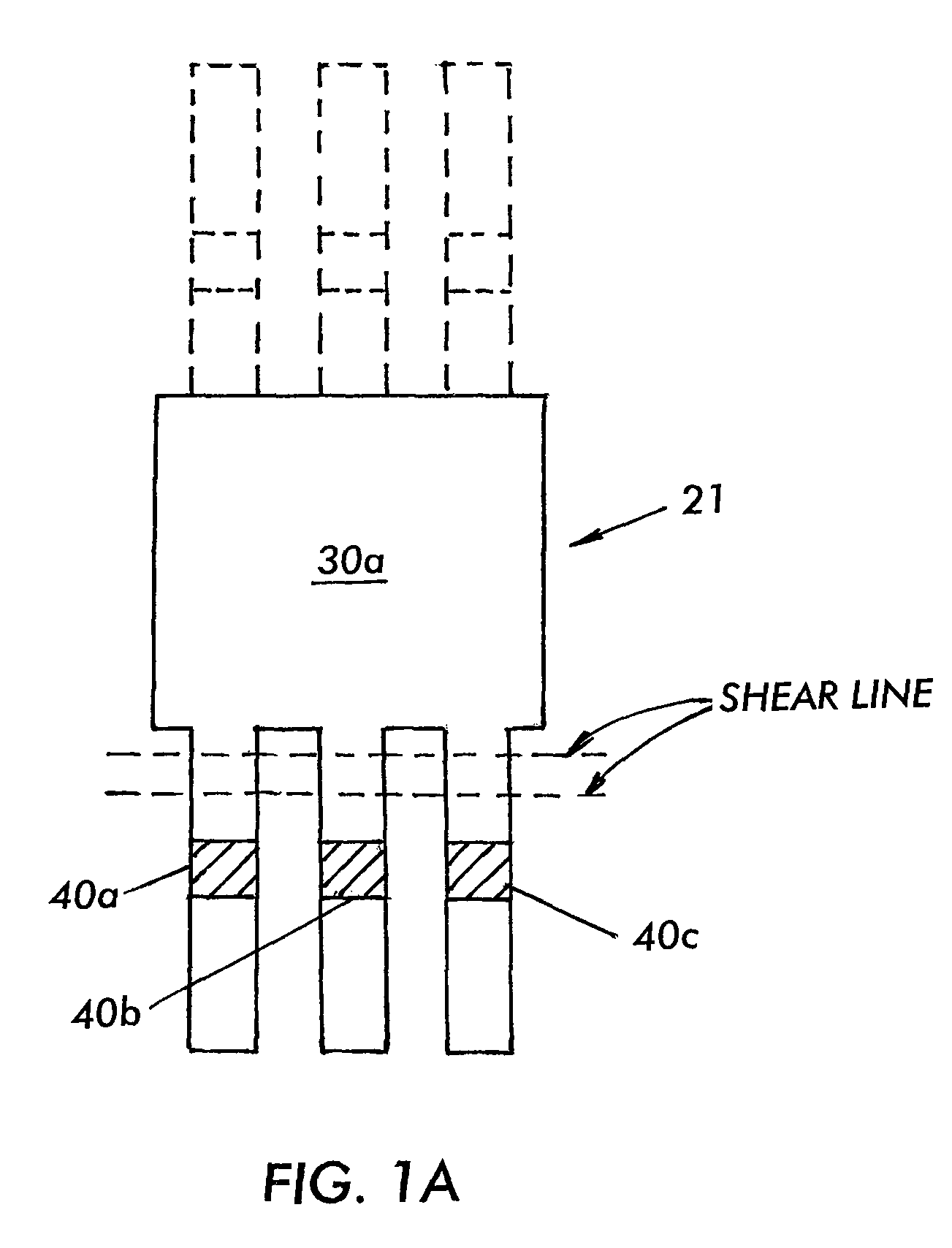

Semiconductor device package with internal device protection

InactiveUS20090279220A1Without impact on footprint and pin compatibilityWell controlled thermal coefficient of resistancePrinted electric component incorporationSemiconductor/solid-state device detailsNegative temperatureSemiconductor package

An integral impedence is formed on or within a lead frame pin of a semiconductor package and receives a connection from an electrode of a semiconductor die within the package to eliminate the need for adjustment and protective impedences external of the package. The impedence comprises passives such as resistors, capacitors, diodes or inductors which modify the performance of the package for new semiconductor device characteristics. The impedences may have positive or negative temperature coefficients and are in close thermal communication with the semiconductor die.

Owner:INFINEON TECH AMERICAS CORP

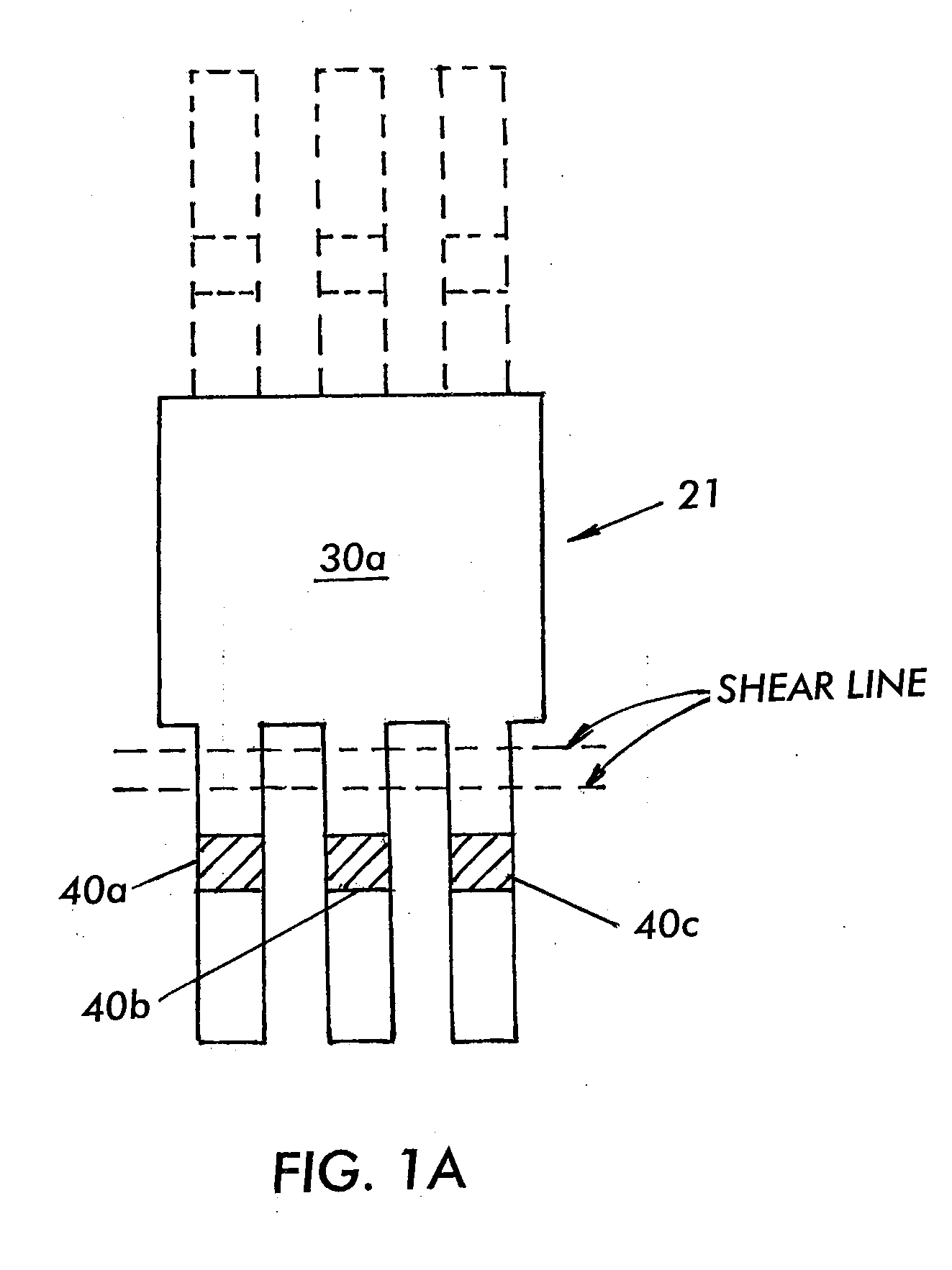

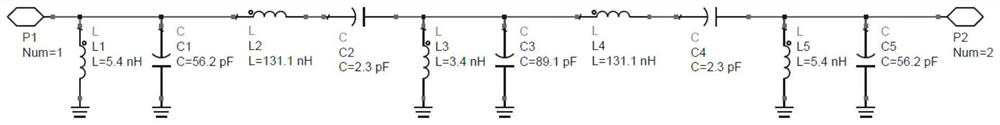

Dual-channel passive device power tolerance testing system

InactiveCN104301049AGuaranteed reliabilityGuaranteed service lifeTransmitters monitoringChannel powerInterference (communication)

The invention relates to a dual-channel passive device power tolerance testing system. The dual-channel passive device power tolerance testing system comprises two signal generators. Both the signal generators are correspondingly connected to signal switches. The signal switches are connected to electric bridges through power amplifiers. Each signal switch is connected with two power amplifiers, and connection is switched through switches. The 3dB electric bridges are connected with diplexers through dual-directional couplers. Loads are hung outside the electric bridges. The forward coupling end and the reverse coupling end of each dual-directional coupler are connected with two terminals of a corresponding dual-channel power meter respectively. The diplexers are connected with spectrometers through detection ports, the diplexers are connected to detection parts, and the detection parts are connected with attenuators through filters. Loads are hung outside the detection parts. The attenuators are connected with the spectrometers. The dual-channel passive device power tolerance testing system judges whether the performance of devices is qualified or not by checking the working states and the technical indexes of the devices in peak power and average power, so that the requirements for communication capacity and communication quality of the whole communication system are guaranteed, and system interference is reduced from the source.

Owner:STATE GRID CORP OF CHINA +1

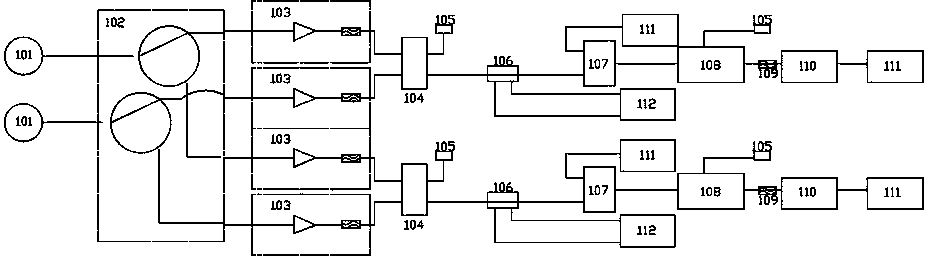

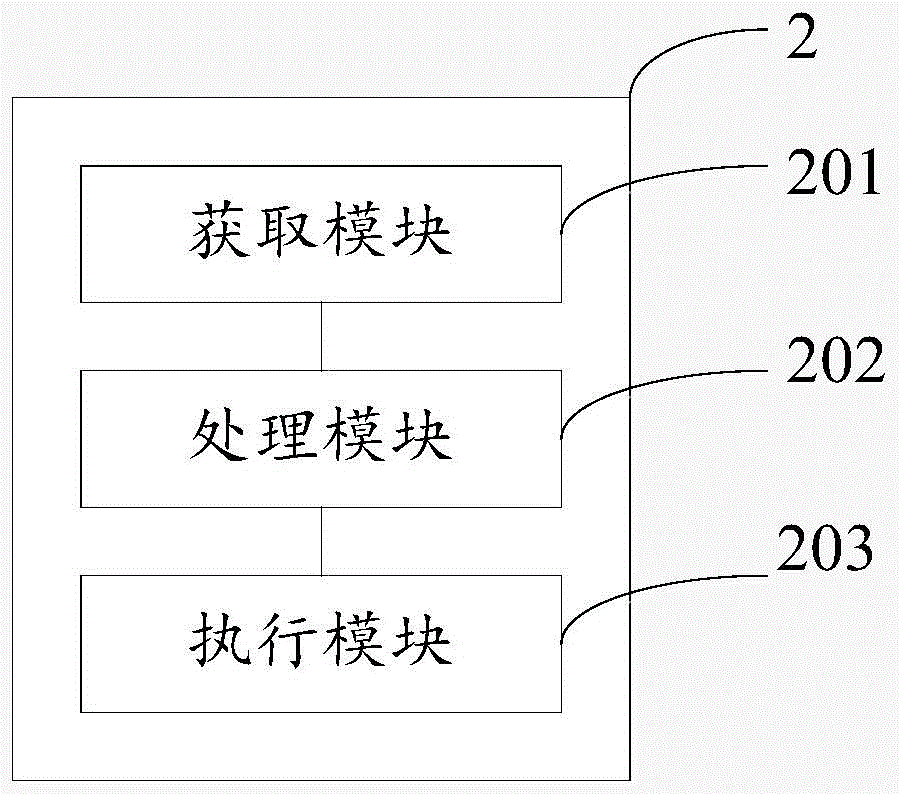

Friend message shielding method and device based on address list

InactiveCN104994009AImprove privacy and securityProtect privacy and securityData switching networksComputer engineering

The invention provides a friend message shielding method and device based on an address list and belongs to the network field. The method comprises the following steps: obtaining a first address list of a user mobile terminal, wherein the first address list is the address list of a first application program; determining at least one object to be shielded according to the first address list and a pre-stored second address list, wherein the second address list is the address list of a second application program; and executing a shielding strategy corresponding to the at least one object to be shielded. The technical scheme can realize bidirectional message shielding between friends, thereby simplifying operation of a user, protecting privacy safety of the user and enhancing user experience.

Owner:GUANGZHOU IAROUND NETWORK TECH CO LTD

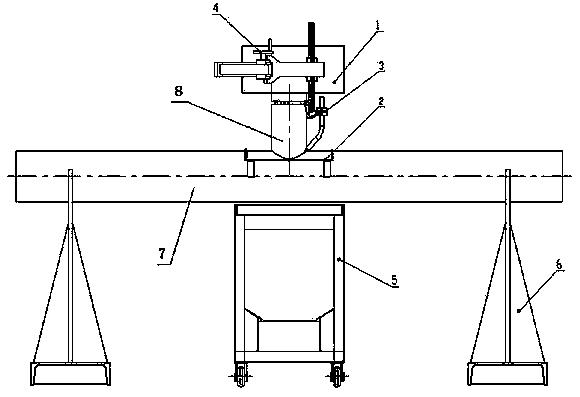

Small-cylinder-diameter-ratio pipe connector submerged arc saddle-shaped automatic welding method

InactiveCN103962694AProtection needsImprove performanceMetal working apparatusTubular articlesEngineeringPhysics

The invention provides a small-cylinder-diameter-ratio pipe connector submerged arc saddle-shaped automatic welding method which is characterized by comprising the steps that a pipe connector is perpendicularly fixed to a cylinder body by bottoming through handmade argon arc welding, a flux protection tool is placed on the surface of the cylinder body so as to support flux needed in welding, and a balance crane is used for placing a submerged arc saddle-shaped automatic welding machine on the pipe connector; due to the fact that a three-jaw chuck on the submerged arc saddle-shaped automatic welding machine extends into the pipe connector, the submerged arc saddle-shaped automatic welding machine can be fixed to the pipe connector, and due to the fact that a saddle fall adjustor and a welding gun angle adjusting valve are adjusted respectively in sequence, different falls and weld bead arrangements are adjusted, and submerged arc saddle-shaped automatic welding is completed. According to the small-cylinder-diameter-ratio pipe connector submerged arc saddle-shaped automatic welding method, small-cylinder-diameter-ratio pipe connector submerged arc saddle-shaped automatic welding is successfully achieved, and the weld appearance is attractive.

Owner:JIANGLIAN HEAVY IND GRP CO LTD

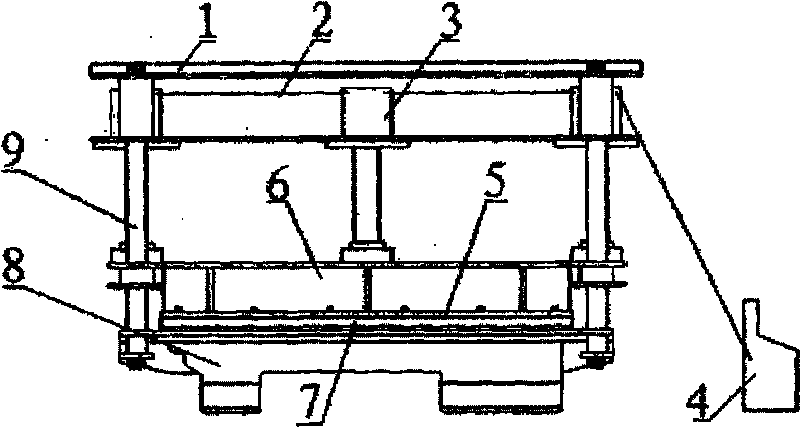

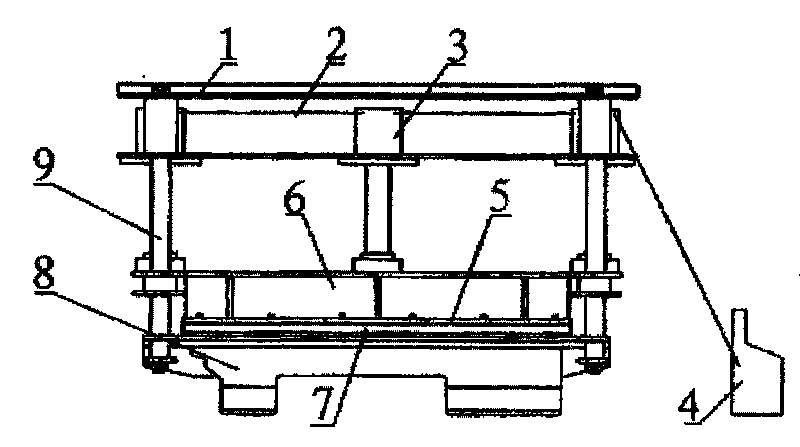

Width corrugated board production line

The invention relates to width corrugated board production line, comprising a rolling plate mechanism, an actuating unit, a control mechanism and a support. The production line is characterized in that: the support (1) of constructional steel structure is connected with a connector (6) by a sliding shaft (9) at the two ends thereof, a working platform (8) is connected on the pedestal and below the connector (6); the actuating unit is fixed below the support (1), the rolling plate mechanism is fixed on the working platform (8); and the actuating unit is electrically connected with the control mechanism (4). The width corrugated board production line can process moulding corrugated plates required by production by one-step moulding on a special mould, can improve production efficiency and meets the requirement of production and product quality.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

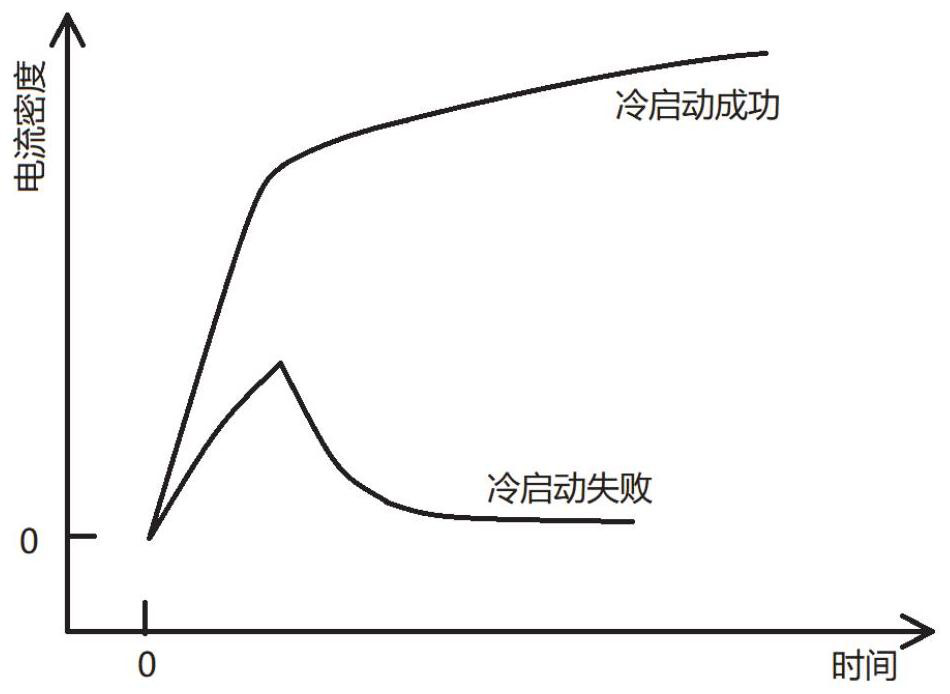

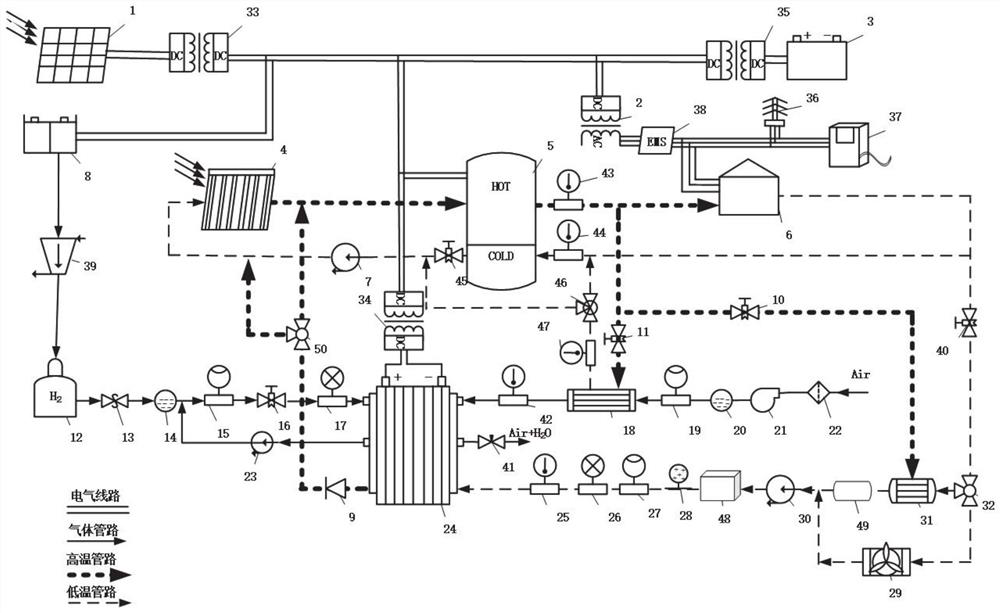

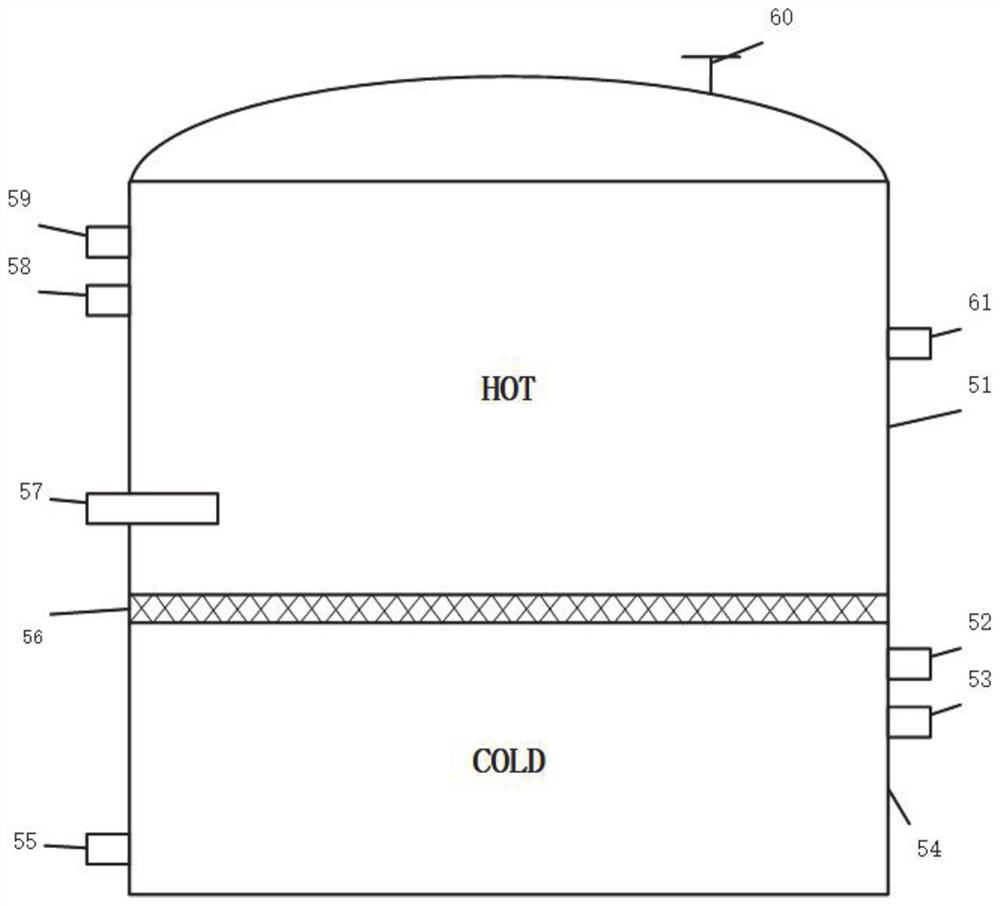

Thermoelectric coupling energy-saving and energy-storing system and method based on hydrogen fuel cell

ActiveCN112820896AStable temperatureEliminate heating deviceFuel cell heat exchangePV power plantsHydrogen fuel cellCollector device

The invention relates to a thermoelectric coupling energy-saving and energy-storing system and method based on a hydrogen fuel cell. The system comprises a fuel cell air inlet module, a fuel cell heat management module, a heat collection and storage device module and a power generation module, the fuel cell air inlet module is connected with a fuel cell electric pile, the fuel cell heat management module comprises a user load, and the heat collection and storage device module comprises a heat storage tank and a heat collector. The power generation module comprises a photovoltaic power generation system and a fuel cell power generation system, and the fuel cell power generation system comprises a fuel cell stack; the power generation module is respectively connected with a user load, the fuel cell air inlet module and the heat collection and storage device module; the heat storage tank is connected with the heat collector; the heat storage tank is respectively connected with a user load and a fuel cell gas inlet module; and the user load is connected with the electric pile. According to the invention, the waste heat of the hydrogen fuel cell system is efficiently recycled, the problem of low-temperature cold start of the hydrogen fuel cell is simplified and optimized, uninterrupted supply of regional heat and electricity is realized, and the greenhouse effect is relieved to a certain extent.

Owner:SHANDONG UNIV

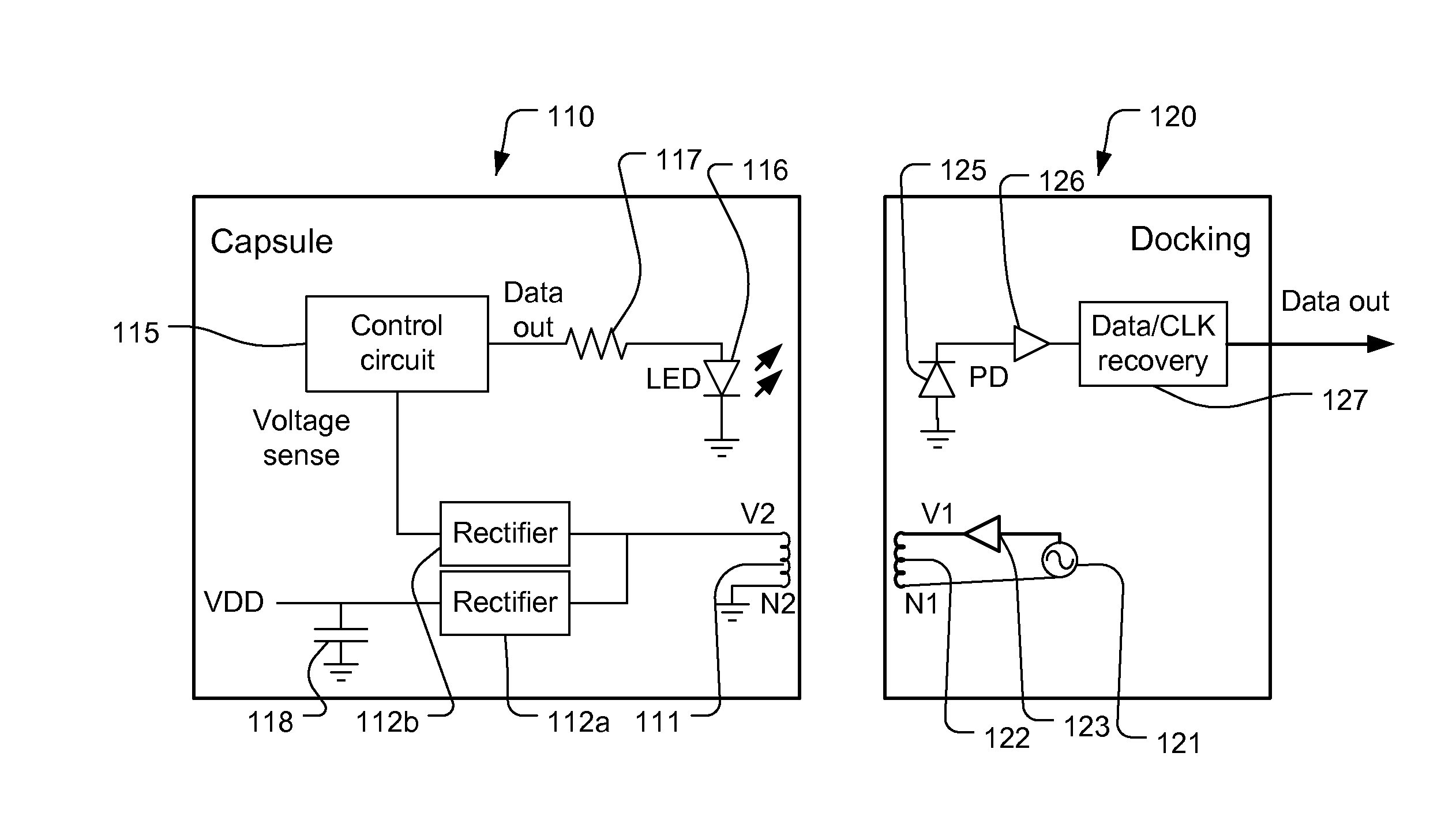

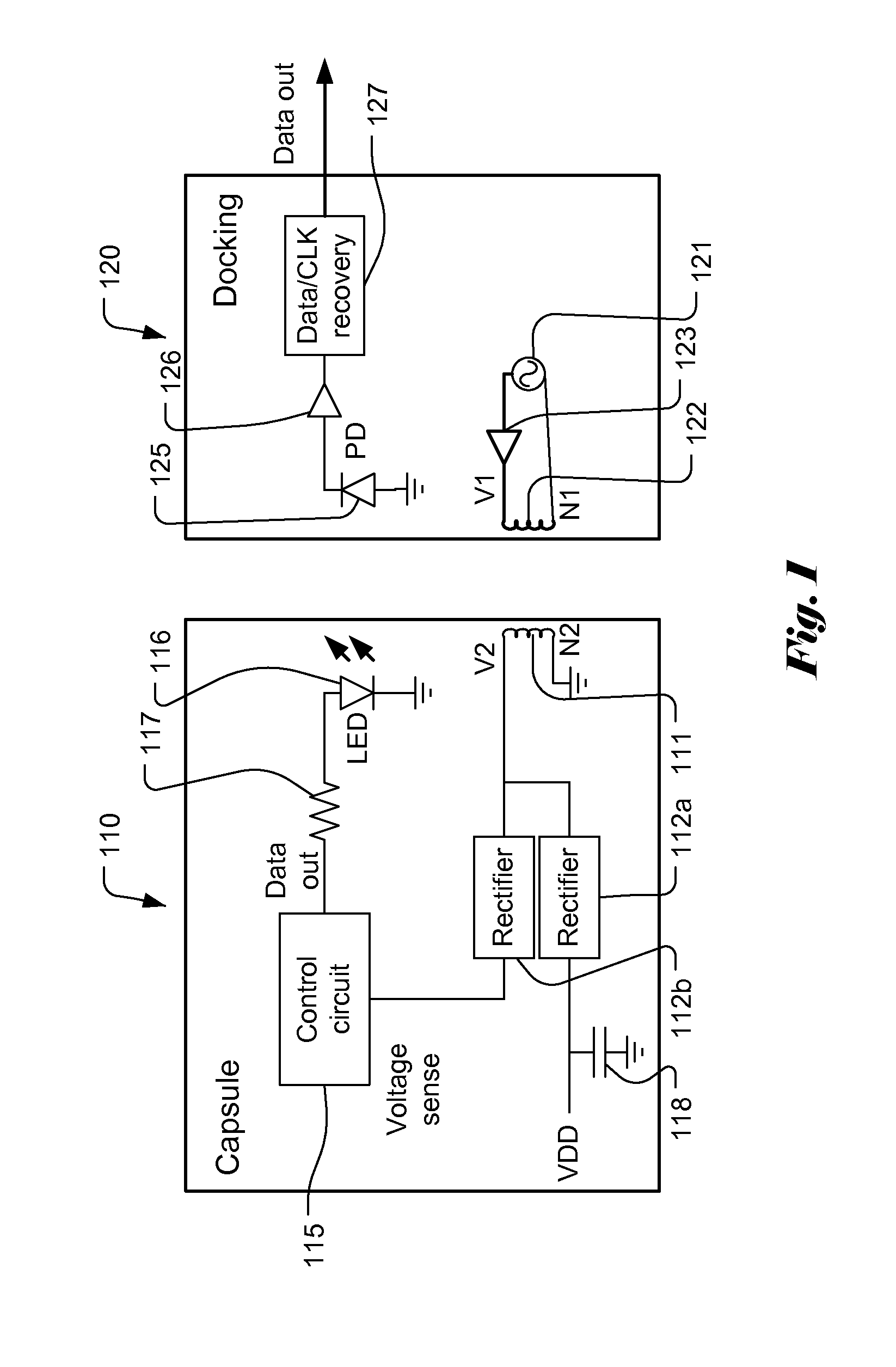

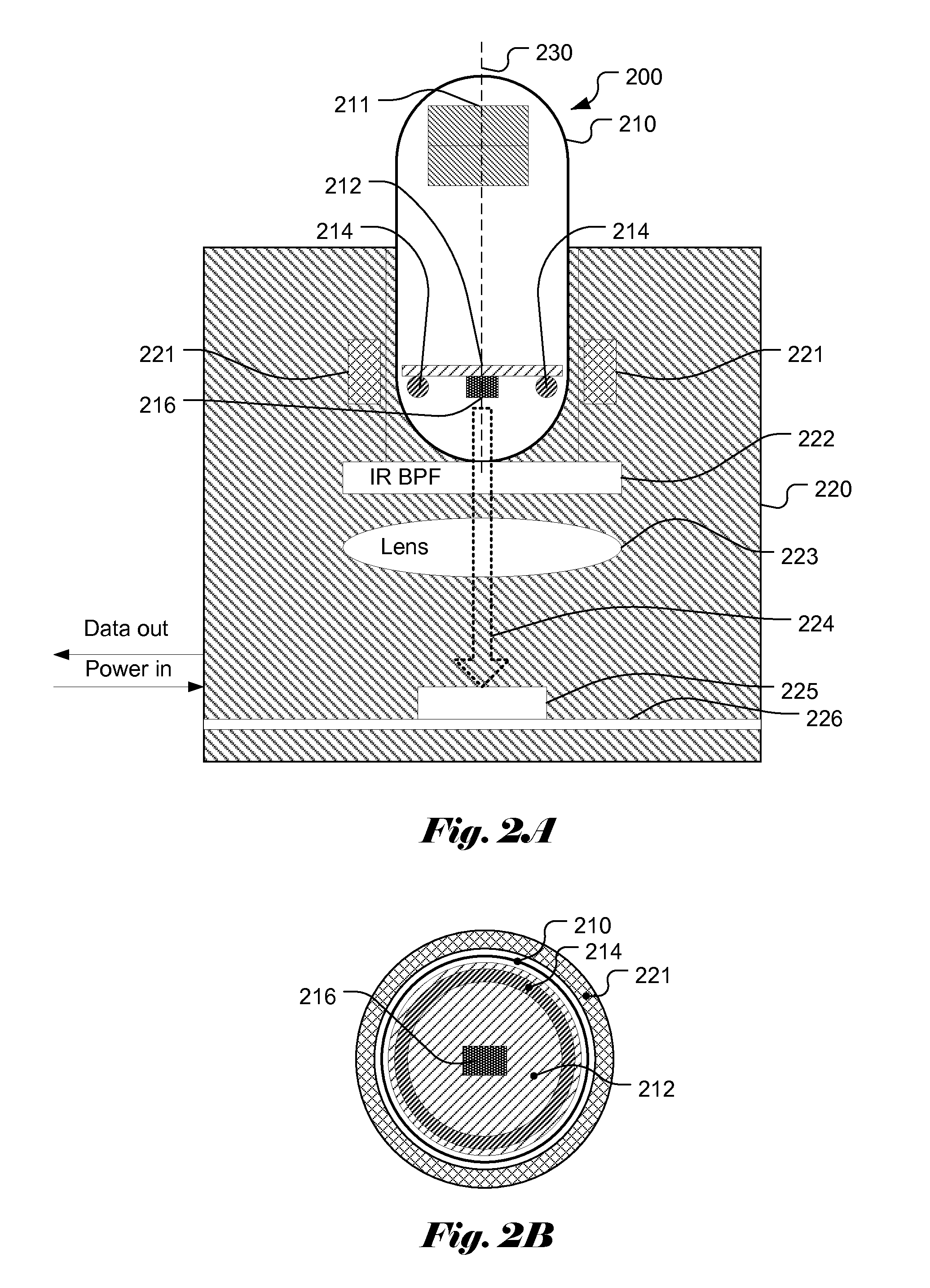

Capsule Orientation Detection for Capsule Docking System with Inductive Power Drive Circuit

ActiveUS20140364688A1Prevent and reduce damageImprove reliabilitySurgeryEndoscopesPower flowControl circuit

A capsule endoscopic system is disclosed for receiving data from a capsule device and providing inductive power to the capsule device wirelessly, where the capsule endoscopic system incorporates a feature to automatically protect the capsule device and the docking device from damage if the capsule device is docked in a backward orientation. In one embodiment, the docking device comprises a current sense circuit to detect the current flowing through the primary coil or primary drive circuit. The occurrence of wrong orientation can be detected from the current. A detection / control circuit can be used to provide the needed control in order to prevent damage to the system. In another embodiment, a resonant circuit comprising a capacitor and the primary coil is used to provide the needed protection when the capsule device is docked with a wrong orientation.

Owner:IGT +1

Slash pine artificial forest transformation technology

The invention discloses a slash pine artificial forest transformation technology. The slash pine artificial forest transformation technology comprises the steps of slash pine forest stand selection standard, a forest stand survey, a single tree survey, forest stand transformation, protection measures and the like. Based on the status quo of slash pine timber forests, forest stands with a good forest stand soil productivity basis are selected, a scientific and reasonable transformation technology is adopted, a single timber wood target is replaced with a multi-purpose forest stand cultivation mode which integrates seedling growing superior tree protection, big-diameter wood cultivation and high-rosin-yield single-plant management, through broad-leaved trees under a forest, the soil productivity is renewed and maintained, the nutrient requirement for timber wood and rosin production is guaranteed, and therefore requirements for different production targets and different interests parties are guaranteed.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Semiconductor device package with internal device protection

InactiveUS8102668B2Without impact on footprint and pin compatibilityWell controlled thermal coefficient of resistancePrinted electric component incorporationSemiconductor/solid-state device detailsNegative temperatureSemiconductor package

An integral impedence is formed on or within a lead frame pin of a semiconductor package and receives a connection from an electrode of a semiconductor die within the package to eliminate the need for adjustment and protective impedences external of the package. The impedence comprises passives such as resistors, capacitors, diodes or inductors which modify the performance of the package for new semiconductor device characteristics. The impedences may have positive or negative temperature coefficients and are in close thermal communication with the semiconductor die.

Owner:INFINEON TECH AMERICAS CORP

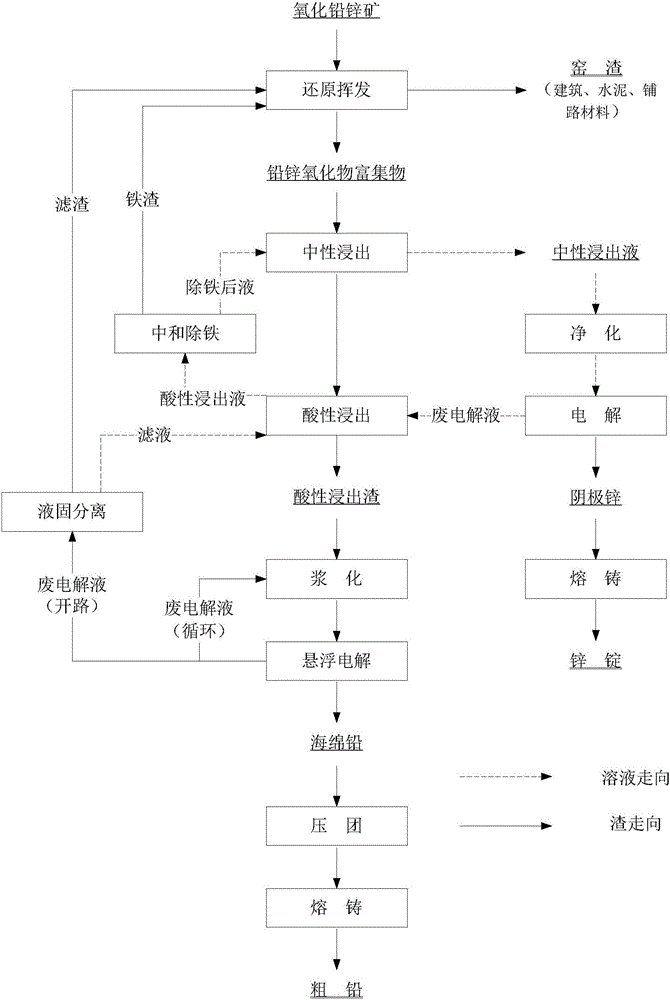

Environment-friendly metallurgy extracting method for lead-zinc oxide ores

InactiveCN106498181AStable in natureQuality improvementPhotography auxillary processesProcess efficiency improvementElectrolysisImpurity

The invention discloses an environment-friendly metallurgy extracting method for lead-zinc oxide ores, and belongs to the field of lead zinc ore metallurgy. The method comprises the following steps: reducing and volatilizing the lead-zinc oxide ores to obtain high-quality lead-zinc oxide enrichment, and separating lead and zinc from other impurities in raw ores; carrying out sulfuric acid leaching-purifying-electrodeposition on the lead-zinc oxide enrichment to obtain cathode zinc, and casting to obtain zinc ingot products; and after slurrying zinc leaching residues, continuously adding in a suspension electrolytic bath for producing lead powder by electrodeposition, and after washing, filtering and briquetting the lead powder, smelting into lead bullion. The lead and the zinc are highly enriched effectively by pyrogenic-process reduction and volatilization, and influence of impurities such as Fe, Si, Ca, Mg and Al to a smelting process is greatly reduced; and the zinc and the lead are effectively extracted in a sulfuric acid system to directly obtain the cathode zinc and the lead bullion, organic circulation of lead and zinc smelting systems is realized, consumption of energy and materials is greatly reduced, meanwhile, 'zero' consumption of sulfuric acid, 'zero emission' of waste water and 'zero' emission of smelting wastes are realized simultaneously, and the environment-friendly metallurgy extracting method for the lead-zinc oxide ores is environment-friendly.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

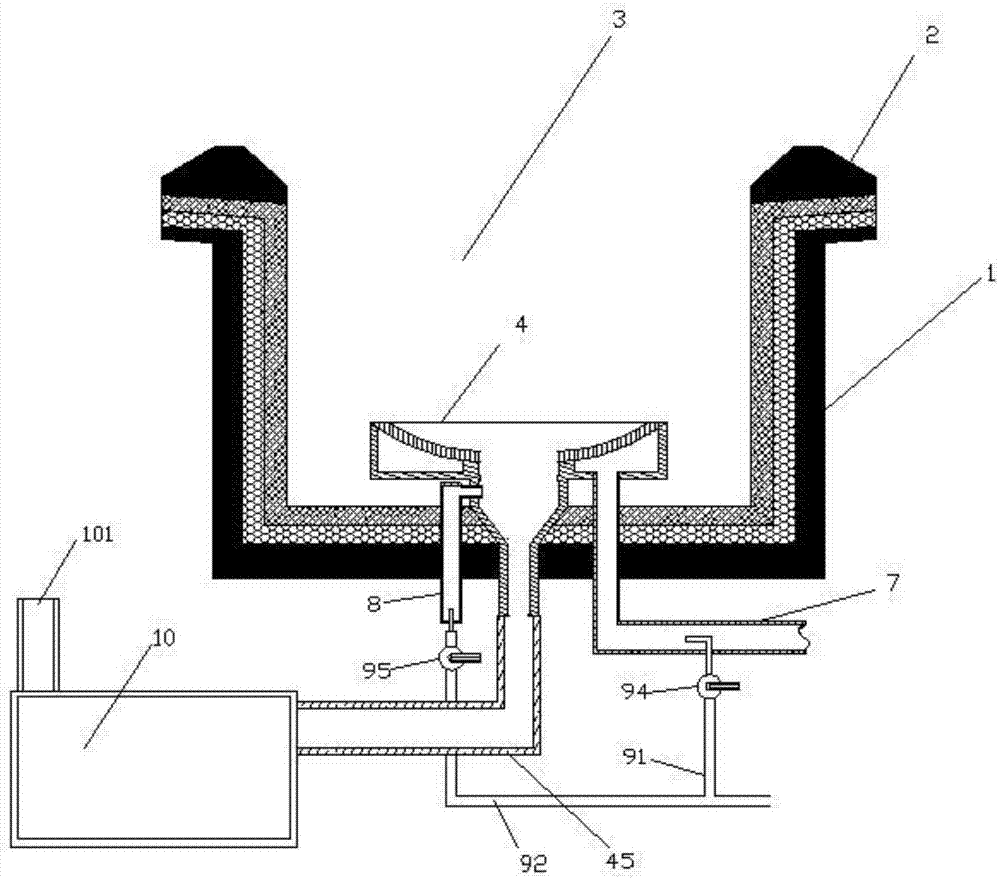

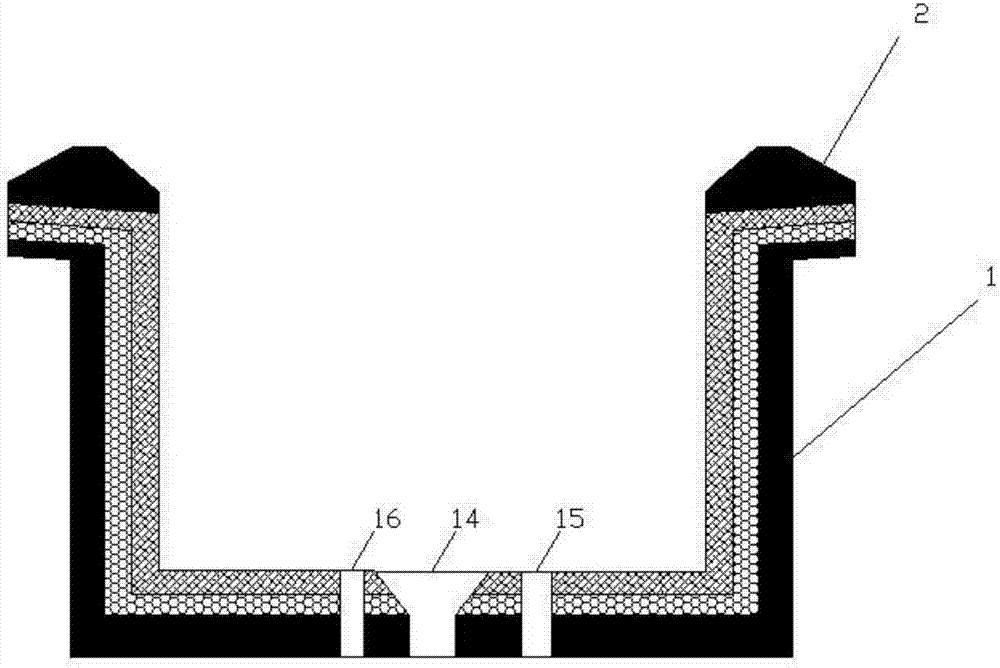

Novel heat energy circulation Chinese frying furnace device

ActiveCN106949503AGuaranteed oxygen supplyHigh heat conversion rateDomestic stoves or rangesStoves/ranges topsCombustion chamberExhaust gas emissions

The invention discloses a novel heat energy circulation Chinese frying furnace device. The device comprises a burner, a hearth, a hearth shell and a frying pan bracket; the burner comprises a combustion plate, a burner bracket and a gas mixing cavity; the bottom of the hearth shell is connected with a waste gas pipe; a heat return water tank is connected through a waste gas pipe; and a waste gas flue is arranged on the heat return water tank. The hearth, the burner and the whole frying furnace system are improved, so that the heat conversion rate of the frying furnace is increased, the oxygen supply in a combustion chamber is guaranteed, and the waste gas discharge pollution problem is solved; and meanwhile, high-temperature waste gas is reused to the greatest extent to effectively prevent such problems as diffusion of the temperature in the hearth.

Owner:东莞市华阳环保节能科技有限公司

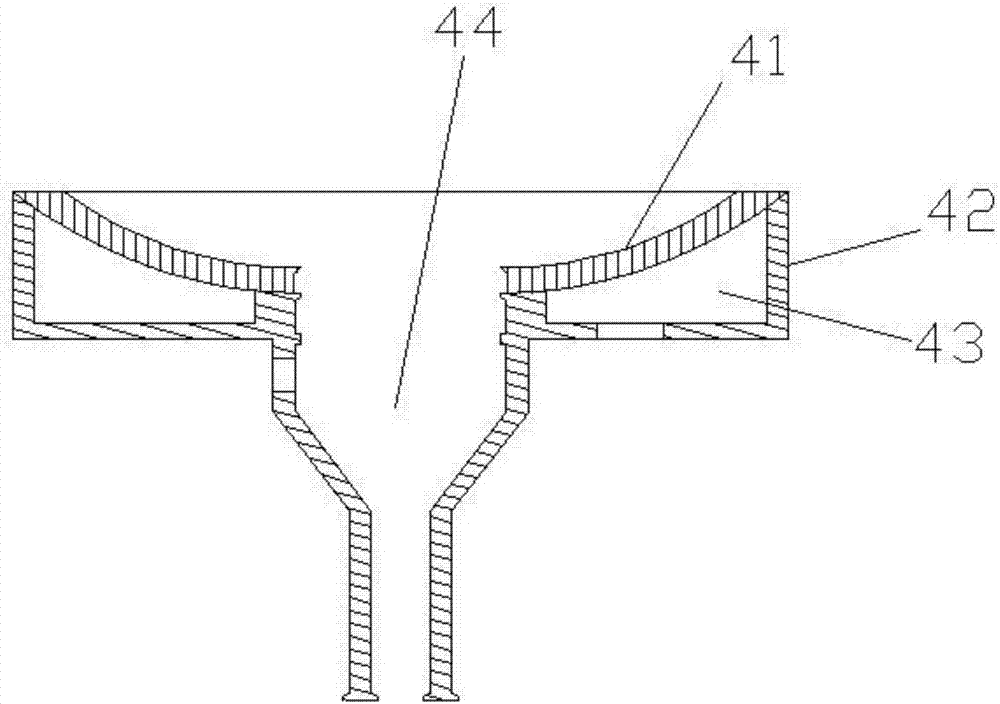

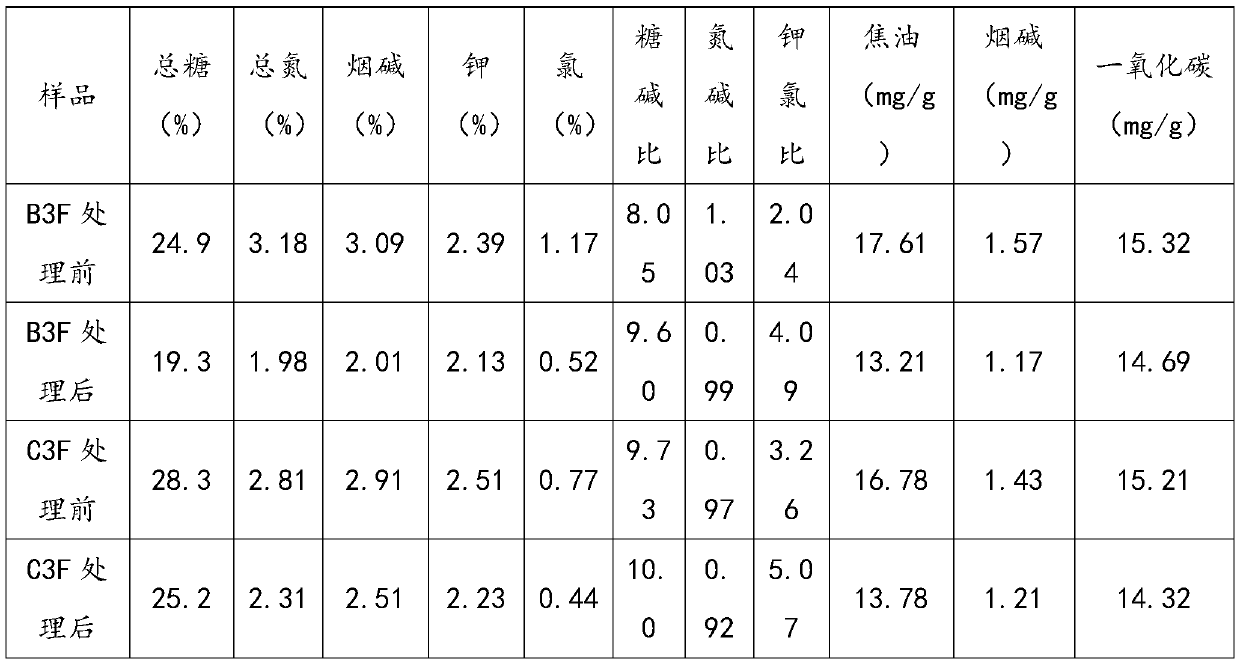

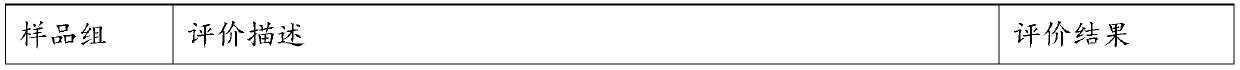

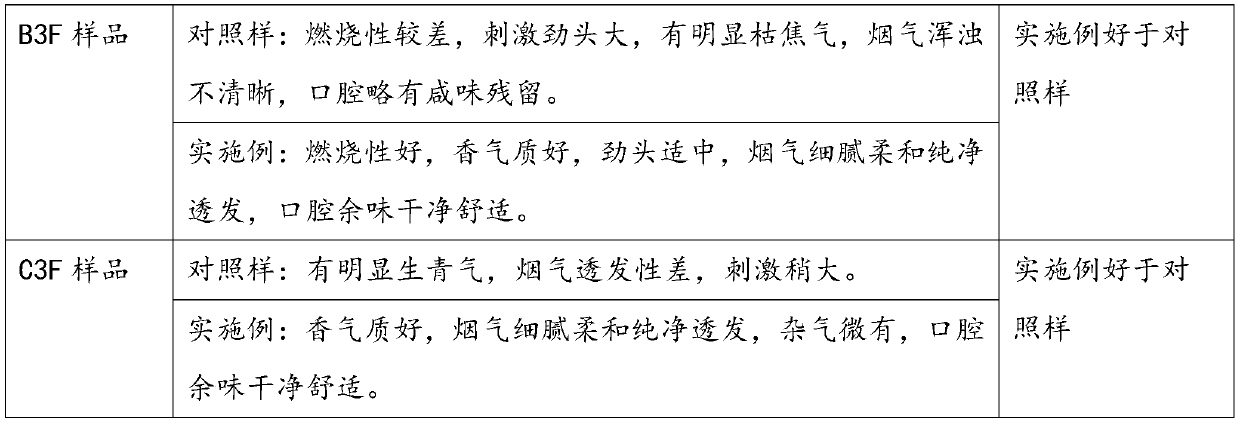

Method of quality improving and harm reducing of tobacco leaves

PendingCN110326813AFragrance texture is clear and transparentClear textureTobacco treatmentCigar manufactureIrritationPhenol

The invention relates to a method of quality improving and harm reducing of tobacco leaves. The method includes the following steps that the tobacco leaves are evenly mixed with water, a synergist anda hydrolysis promoting agent, hydrolysis is conducted, and solid liquid separation is conducted; and the hydrolyzed tobacco leaves are loosened and dried. By adopting the tobacco leaf processing treatment method capable of effectively reducing the negative influences of chemicals contained in the tobacco leaves through the hydrolysis effect and dissolving-out separation of parts of matter, when the treated tobacco leaves are smoked, smoke is fluffy and fine, aroma clarity and purity are better, offensive odors and irritation are reduced, the aftertaste is clean and comfortable, formulation application is improved, meanwhile, harmful components in the tobacco leaves and human body harmful components such as tar, carbon monoxide, methanol, phenol and ammonia in the smoke generated during burning are reduced, and the safety of smoking cigarettes is improved.

Owner:郝连顺 +2

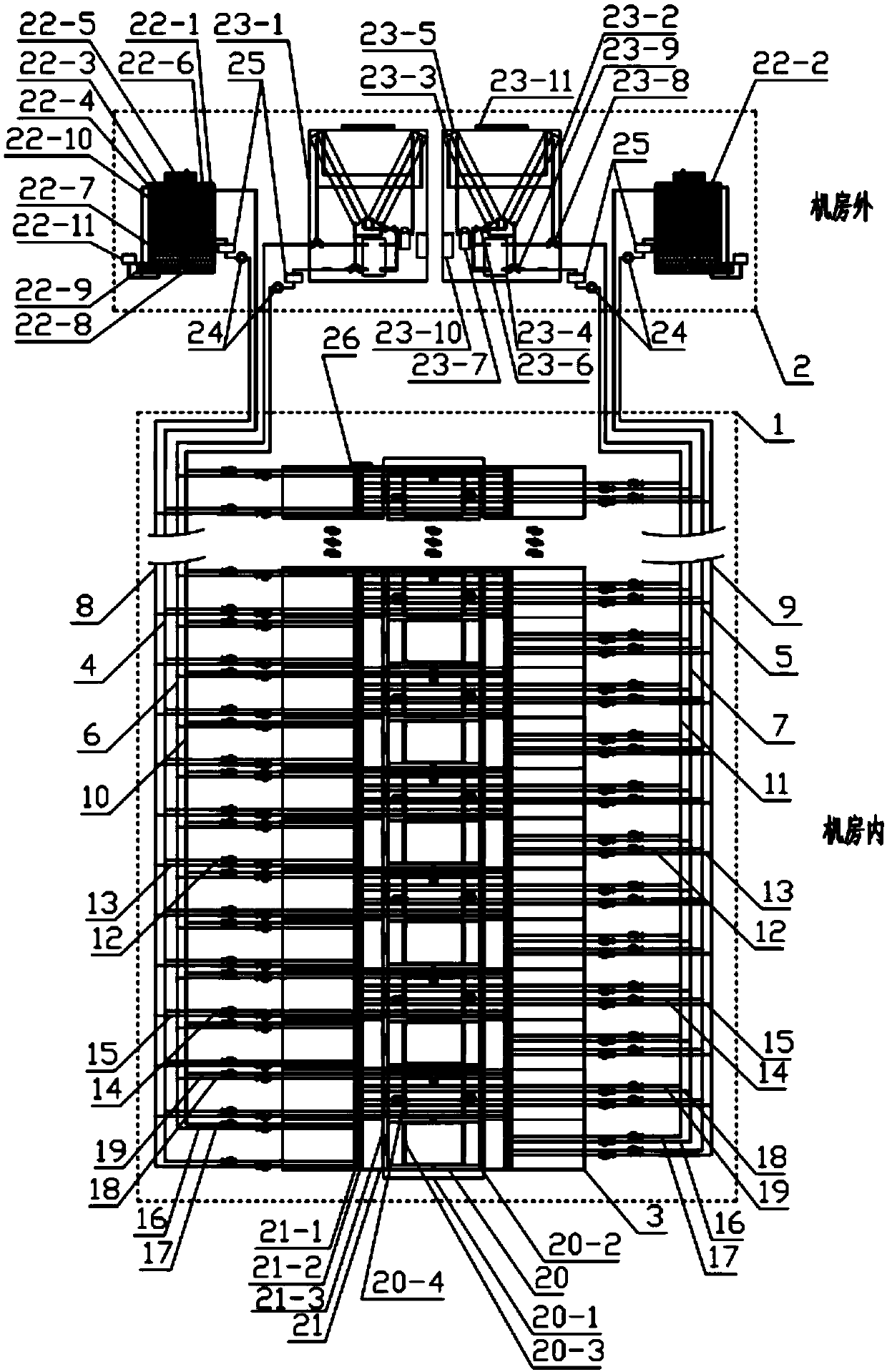

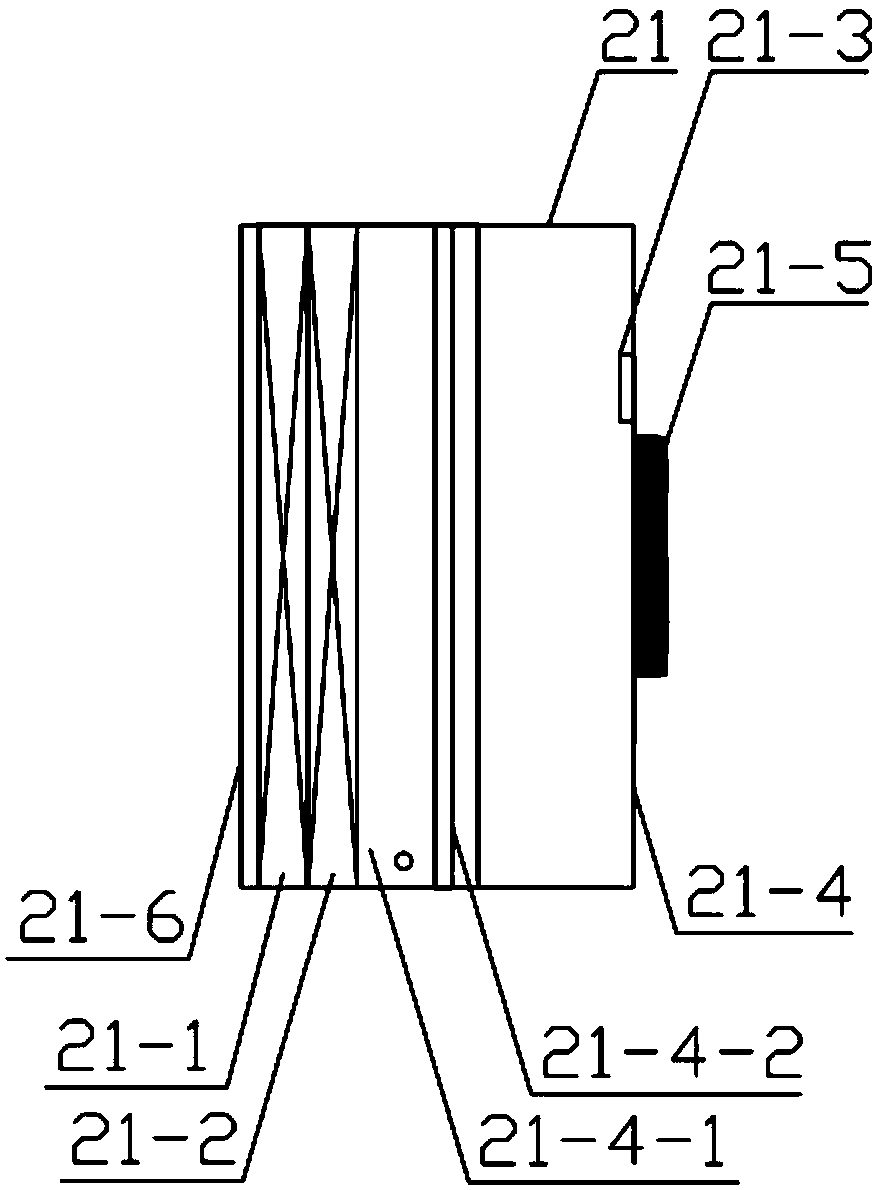

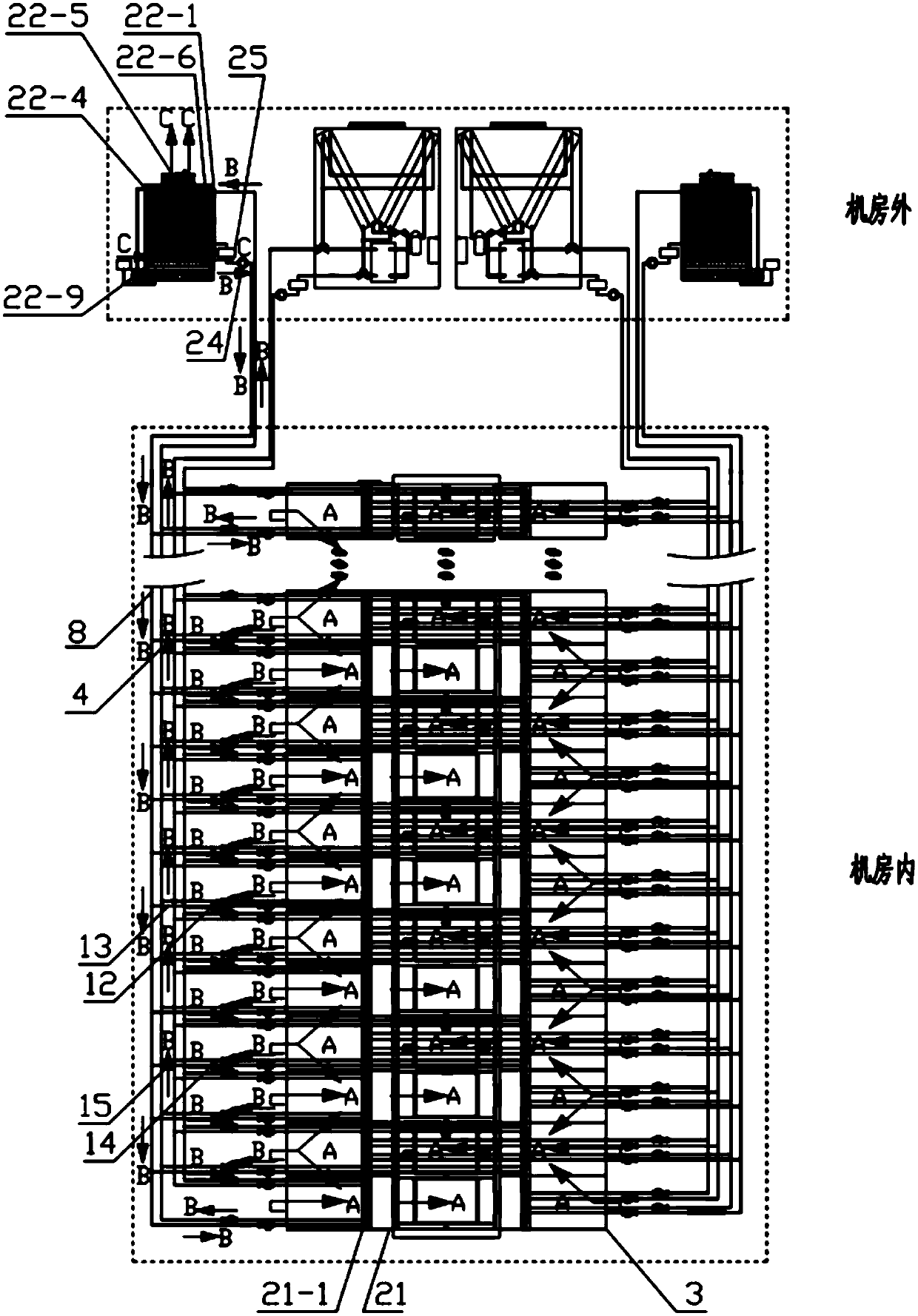

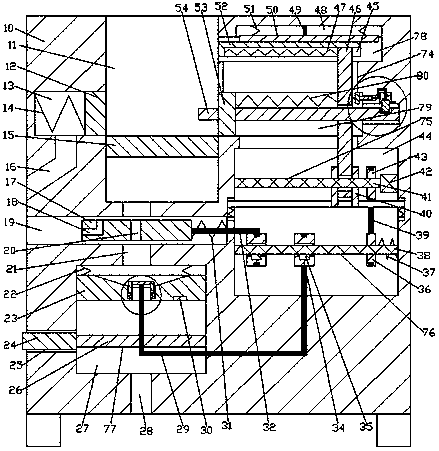

Double-circulation type overhead heat pipe micro-module

PendingCN109539388AProtection needsGuaranteed cooling requirementsMechanical apparatusCondensate preventionEvaporationComputer module

The invention provides a double-circulation type overhead heat pipe micro-module. According to the micro-module, an outdoor cooling unit adopts a design of double natural cooling module and a double outdoor cooling system, a plurality of different condensation supply modes such as air cooling, water spraying evaporation, compression refrigeration, chilled water cooling are provided, in the plurality of condensation modes, the air cooling which is a natural cooling mode is preferentially used, the water spraying evaporation, the compression refrigeration or the chilled water cooling are as a supplementary, and the overall heat discharge capacity of the micro-module and the redundant heat discharge requirements are guaranteed while a natural cooling source is fully utilized. An outdoor cooling loop adopts a mutual backup mode, wherein a first heat exchange loop and a second heat exchange loop mutually back up, any one of the two loops can be selected to operate or the two loops can operate simultaneously; a third heat exchange loop and a fourth heat exchange loop mutually back up, any one of the two loops can be selected to operate or the two loops can operate simultaneously; and when one set of heat exchange loop breaks down, the other set of heat exchange loop normally operates, so that the normal operation of one of two opposite overhead heat pipes can be guaranteed, and the heat dissipation supplement requirements of machine cabinets and the uniform heat dissipation requirements of the micro-module are guaranteed.

Owner:BEIJING NYF SCI & TECH DEV CO LTD

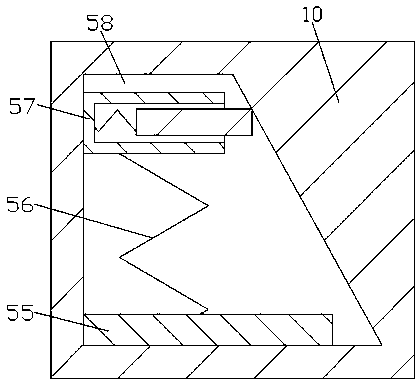

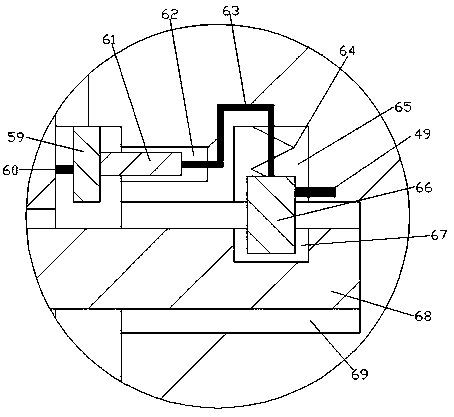

Metal-cutting machine tool chip liquid coarse-fine double-layer outer filtering system

ActiveCN110293446AProtection needsSimple structureMaintainance and safety accessoriesFilter systemEngineering

The invention discloses a metal-cutting machine tool chip liquid coarse-fine double-layer outer filtering system which comprises a filtering machine. A coarse filtering chamber with an upward openingis arranged in the filtering machine; a filter screen with macropores is arranged in the coarse filtering chamber; a piston chamber with a rightward opening is arranged in the left end wall of the coarse filtering chamber; a piston and a reset spring capable of resetting the piston are arranged in the piston chamber; an impurity discharging pipeline communicating with an outside space is arrangedon the lower end wall of the piston chamber; a pushing mechanism capable of cutting off the coarse filtering chamber is arranged in the right end wall of the coarse filtering chamber; and a fine filtering mechanism is further arranged in the lower end wall of the coarse filtering chamber. The device is simple in structure and convenient to operate; the device can take and use a cutting fluid afterfine filtering or coarse filtering at will, so that the demand on the cutting fluid is guaranteed; through mechanical transmission, the speed of fine filtering is accelerated, and the filtering quality is improved; and through automatic operation, impurities on the filter screen are taken out, so that coarse filtering is ensured to be carried out normally, and the filtering efficiency is furtherimproved.

Owner:JIANGSU TONGDA MACHINERY

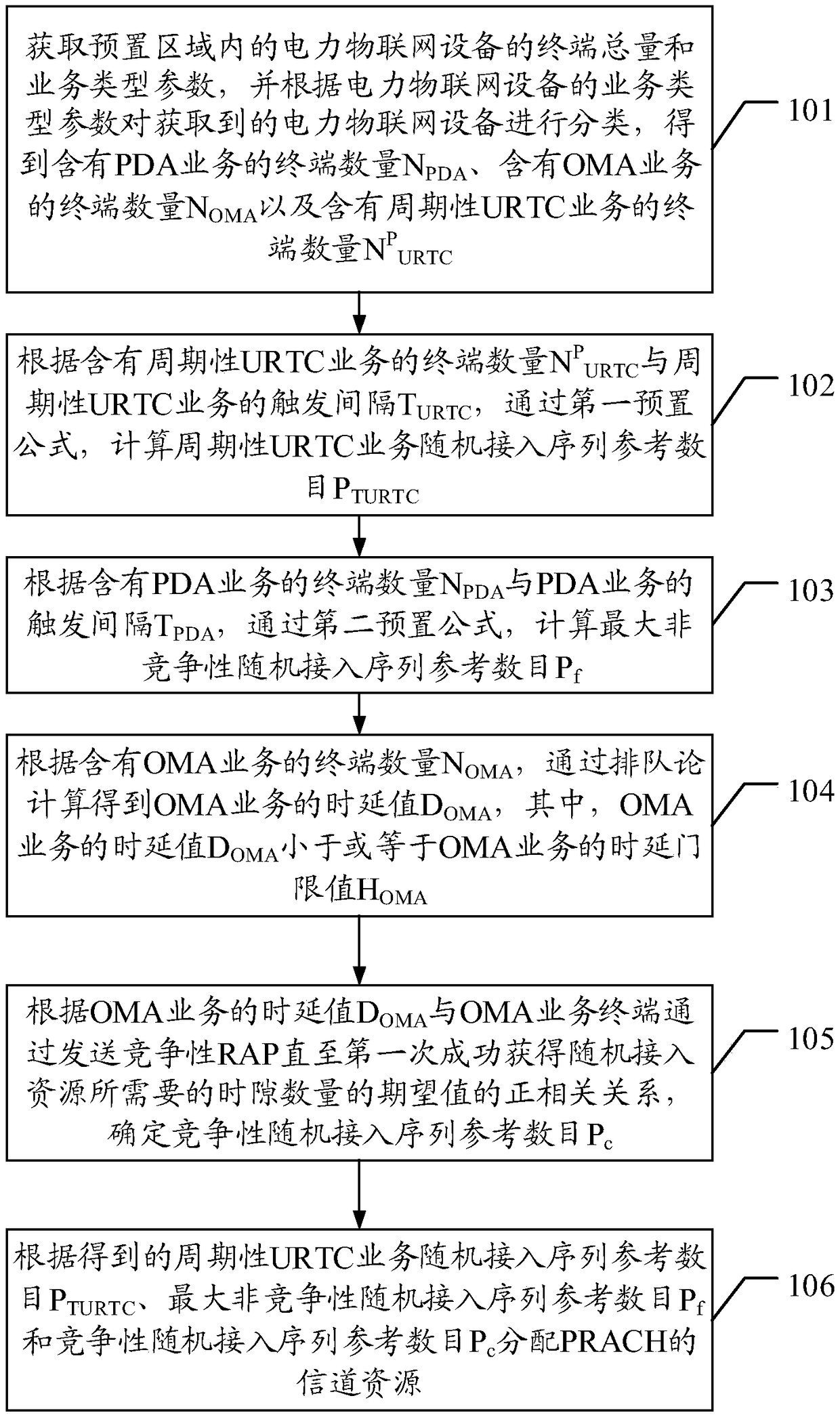

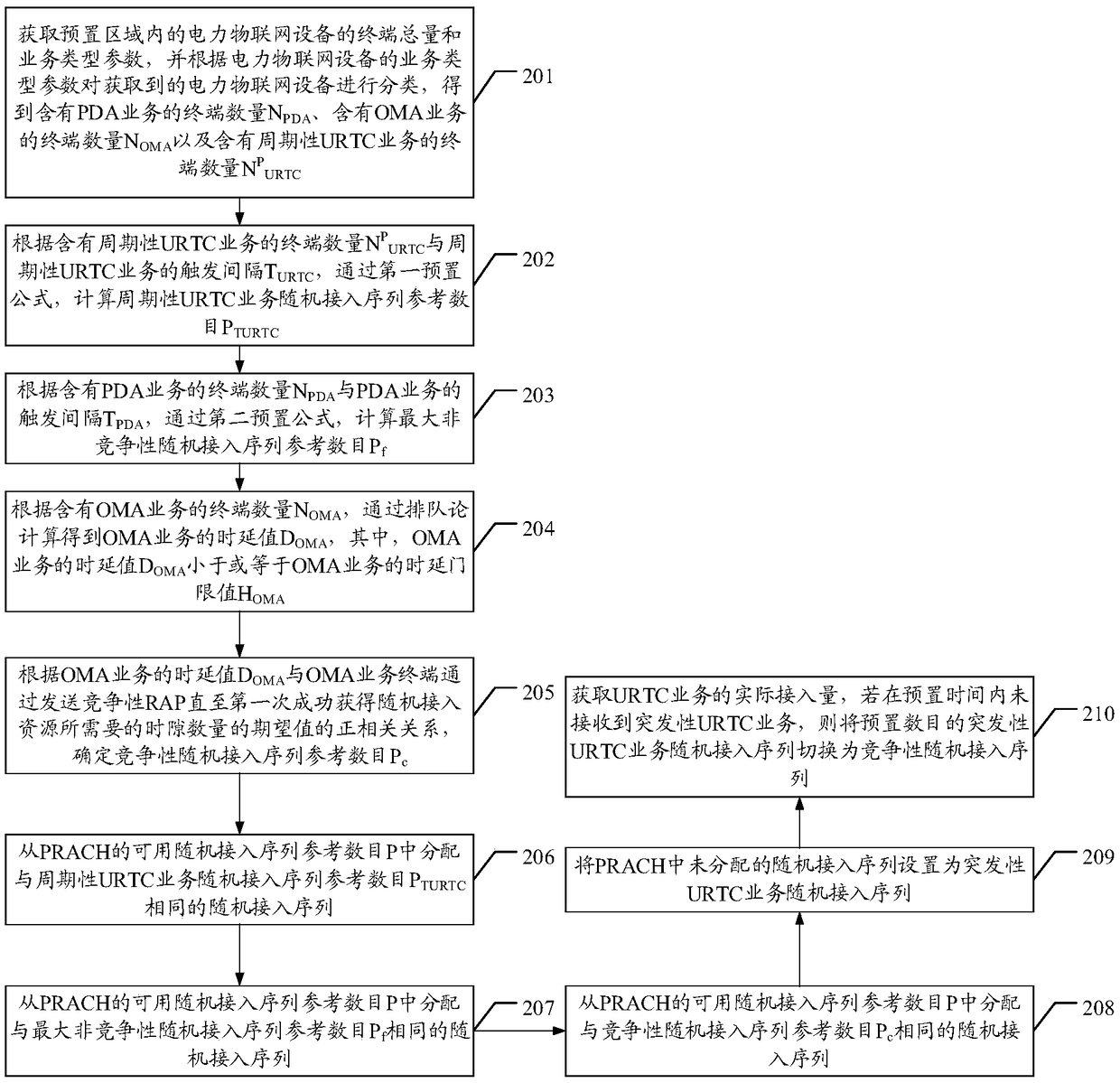

Random access optimization method and device of power IOT (Internet of Things) service

ActiveCN108901078AMeet differentiated QoS requirementsProtection needsHigh level techniquesWireless communicationGranularityElectric power

The invention discloses a random access optimization method and device of power IOT (Internet of Things) service. The random access optimization method of power IOT service provided by the invention is based on a service driving granularity random access new mechanism, and comprises the steps that by aiming at periodic and power predicating service, noncompetitive random access sequences are reserved in advance and are distributed; channel resources are correspondingly accessed; the service access period and time delay requirements are guaranteed; by aiming at sudden service with sudden performance and different time delay sensitive levels, a proper scale of competitive random access resources are provided for terminal competitive random access; the carrying capability of the power IOT oneach kind of service is optimized; the conflict probability of random access of massive power IOT equipment is reduced; the time delay of various types of service of the power IOT is effectively reduced; the differential QoS requirement of various types of service of the power IOT is better met.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

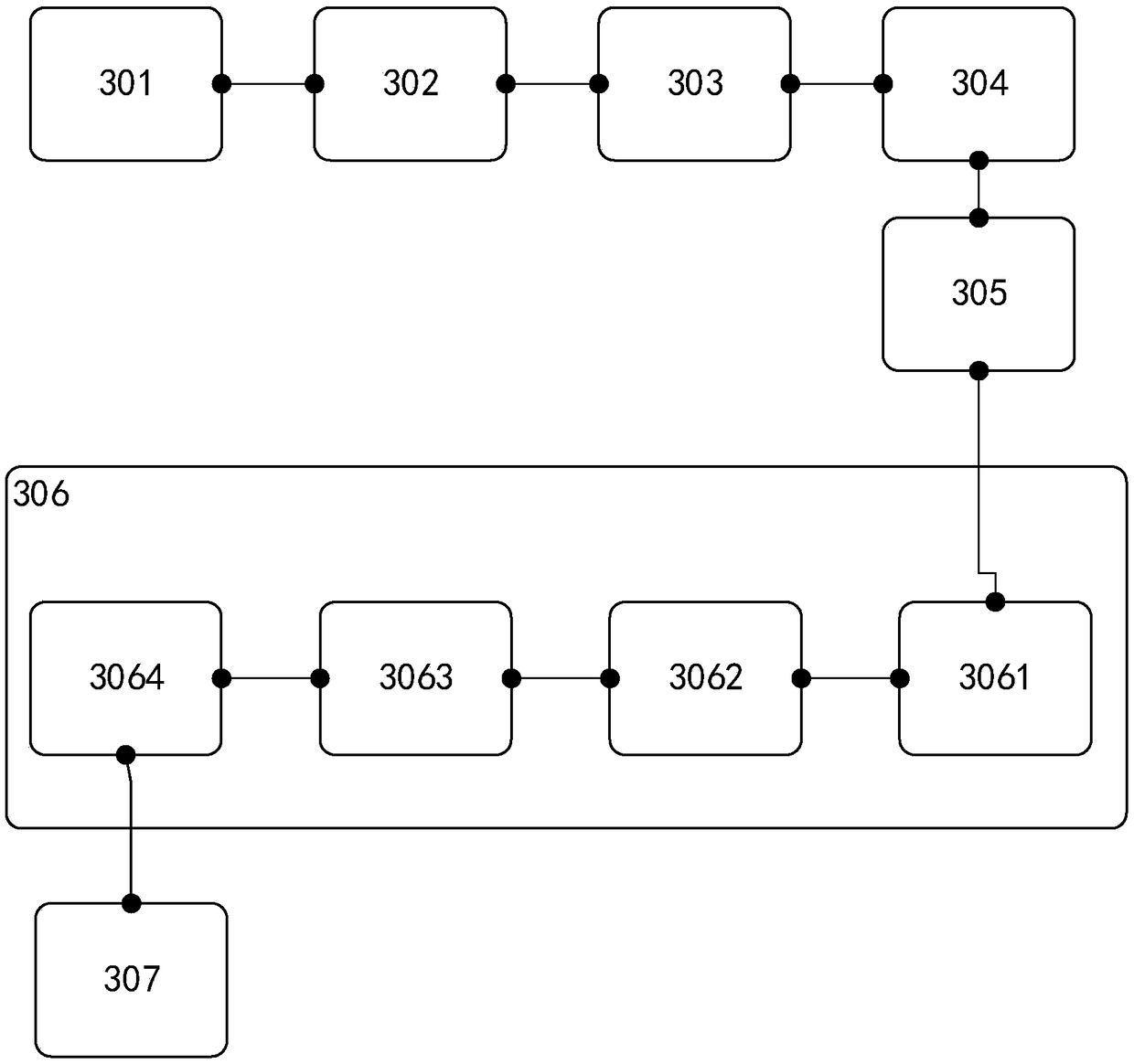

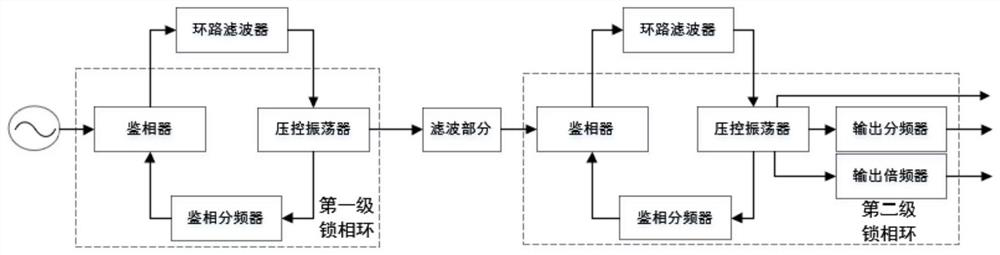

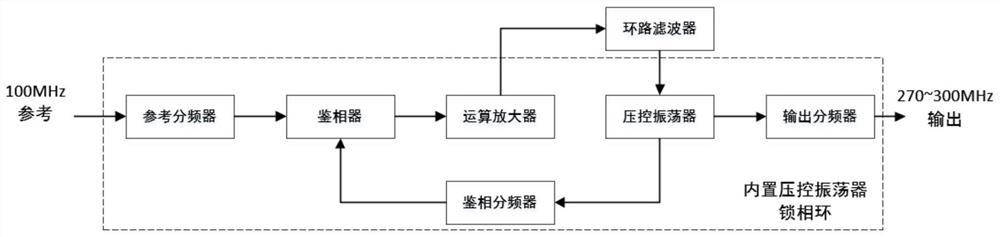

Ultra-wideband low-spurious double-phase-locked loop frequency source

PendingCN112491415AImprove edge spursImprove spurious indicatorsPulse automatic controlLow noisePhase noise

The invention discloses an ultra-wideband low-spurious double-phase-locked loop frequency source, which comprises a reference clock signal, a first-stage phase-locked loop part, a filtering part and asecond-stage phase-locked loop part, wherein the reference clock signal provides a reference signal for the first-stage phase-locked loop part; the first-stage phase-locked loop part performs calculation according to the reference clock signal and the output frequency of the second-stage phase-locked loop, and selects a low-stray and low-noise frequency corresponding to the output frequency of the second-stage phase-locked loop; the filtering part performs narrow-band filtering on the low-spurious frequency points output by the first-stage phase-locked loop part, and a filtered signal can beused as a reference signal of a second-stage phase-locked loop; and the second-stage phase-locked loop part performs broadband frequency modulation according to the reference signal provided by the preceding stage to obtain a broadband signal with low spurious and low phase noise. The low-spurious, low-noise and wide-band design target is achieved, spurious indexes can be improved, meanwhile, thecircuit design is simple and easy to achieve, the reliability of the system can be improved, and good economic benefits and application prospects are achieved.

Owner:北京中科飞鸿科技股份有限公司

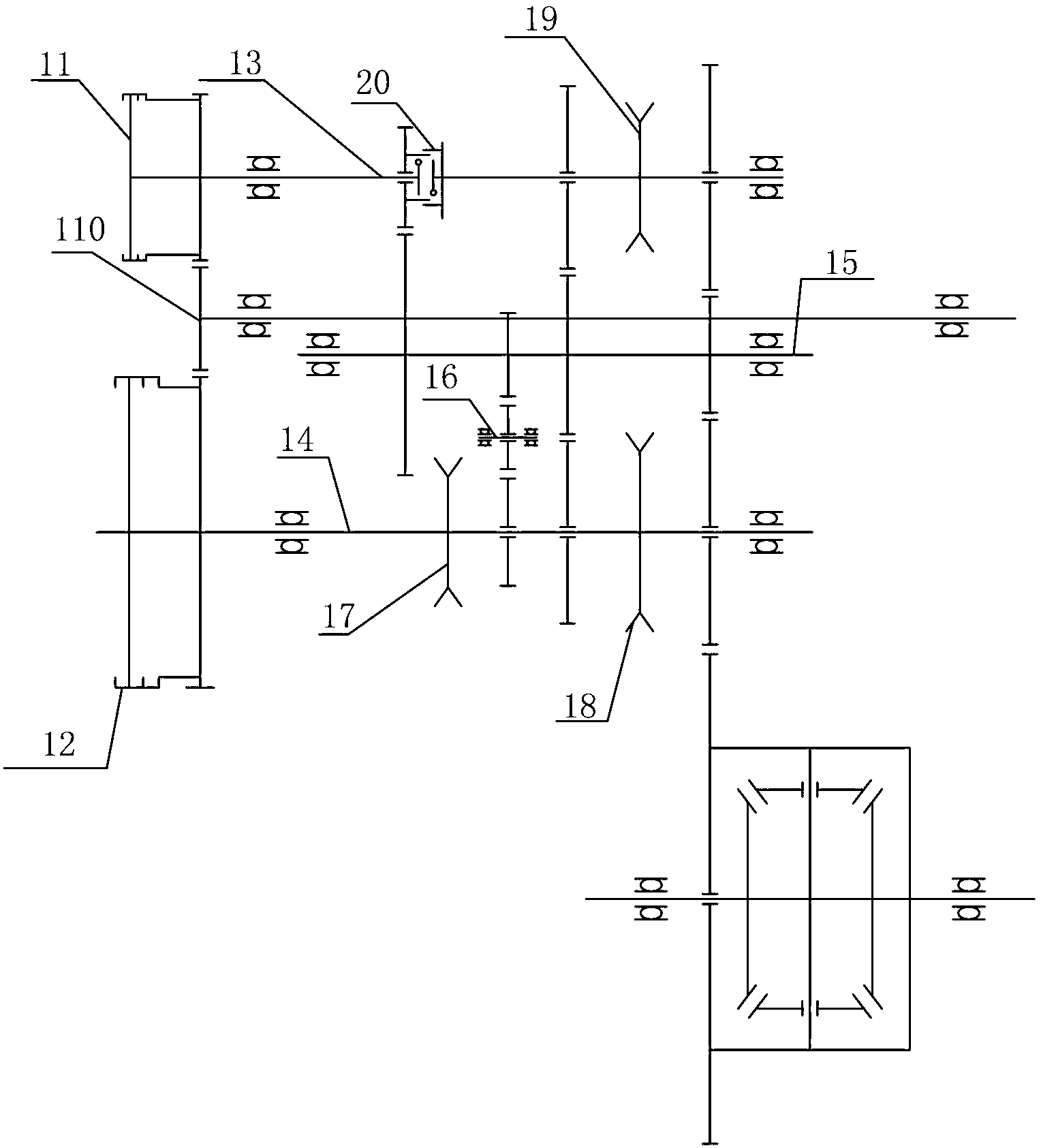

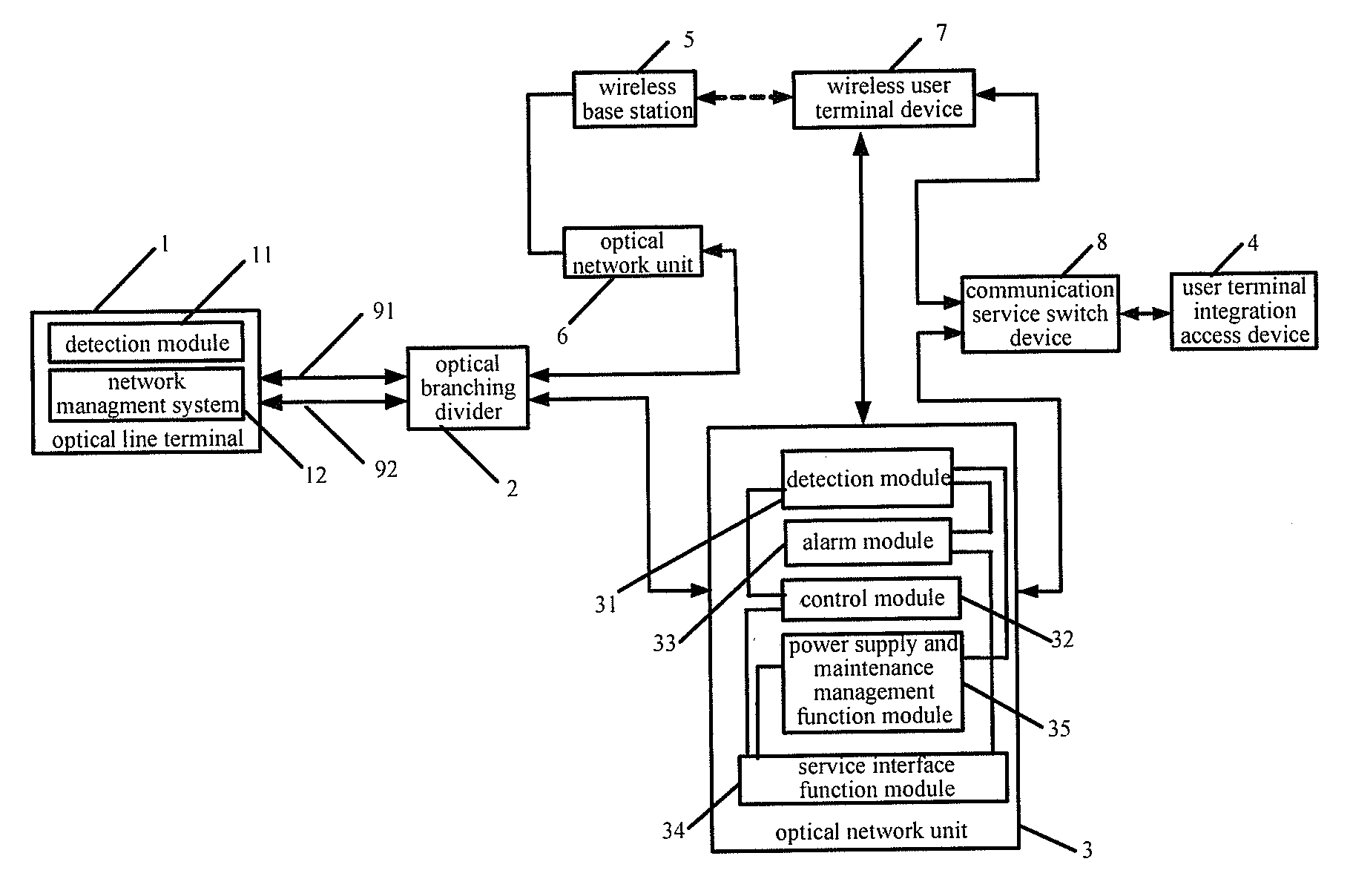

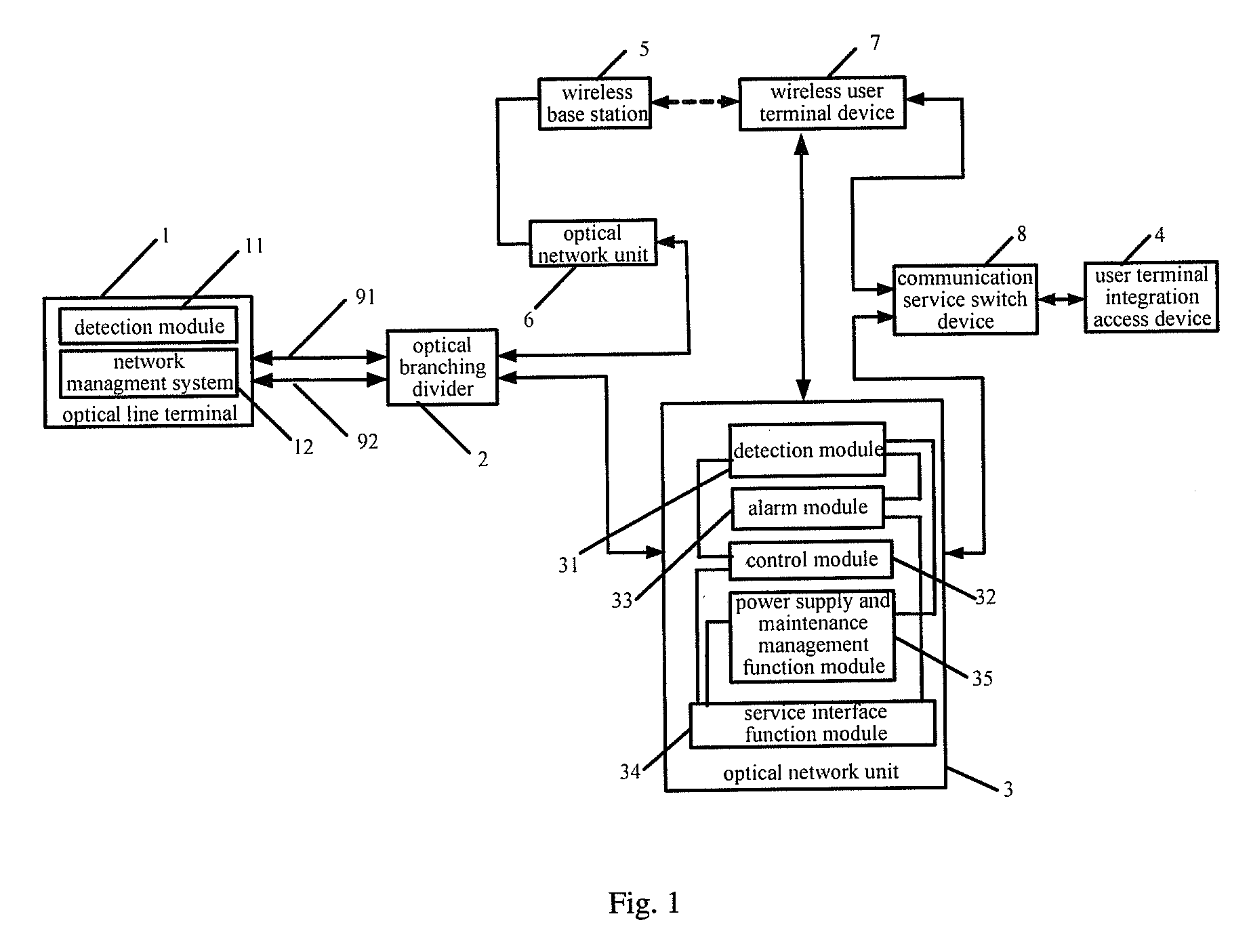

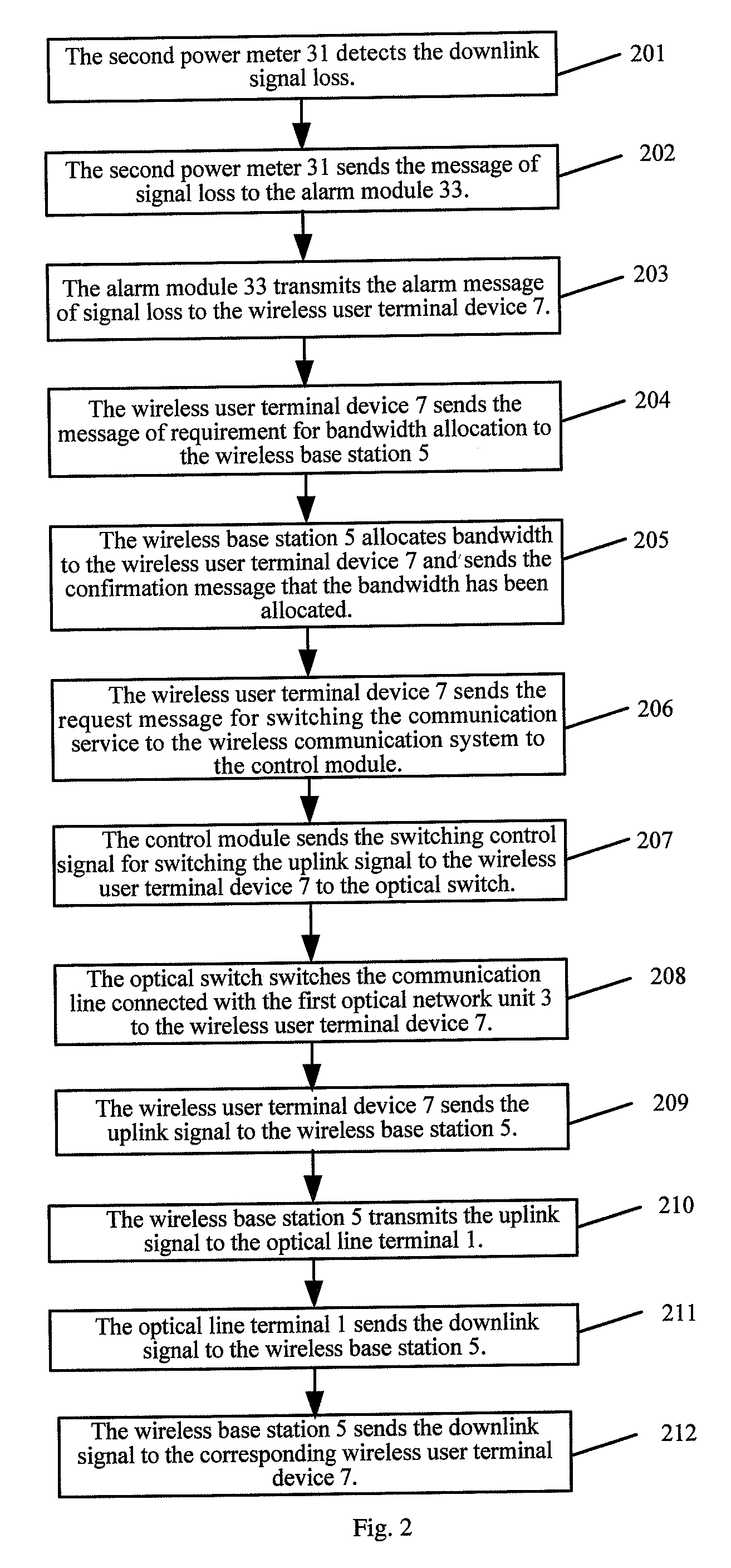

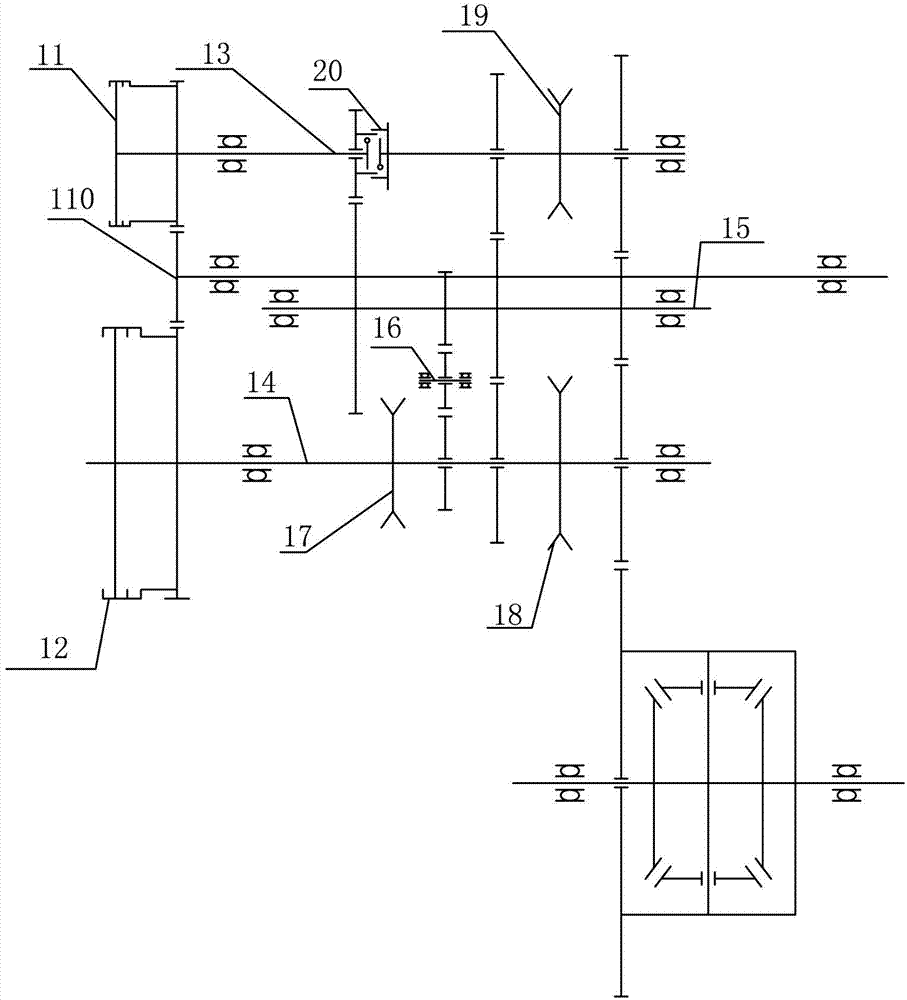

Optical Fiber Access Network and Commuication Protection Method Thereof

ActiveUS20090148168A1Quick coverFacilitate utilizationLaser detailsNetwork traffic/resource managementAccess networkCommunications system

The present invention relates to an optical fiber access network and a communication protection method thereof. The optical fiber access network comprises an optical fiber communication system, a wireless communication system, a communication service switch device (8), a second optical network unit (6) and protection optical fiber (91, 92). The protection optical fiber (91, 92) is used to protect the optical fiber line between the optical line terminal (1) and the optical branching divider (2) in the optical fiber communication system. At the same time, the wireless communication system is introduced to protect the optical fiber between the optical branching divider (2) and the optical network unit (3) in the optical fiber communication system. The protection optical fiber or the wireless communication system is used to protect the communication service respectively when there is a broken failure between the optical line terminal (1) and the optical network unit (3) in the optical fiber communication system. This invention overcomes the limit of the resource, such as pipe, cable, and so on. It can protect communication service of the optical fiber communication system efficiently, and improve the bandwidth utility of the communication system.

Owner:CHINA MOBILE COMM GRP CO LTD

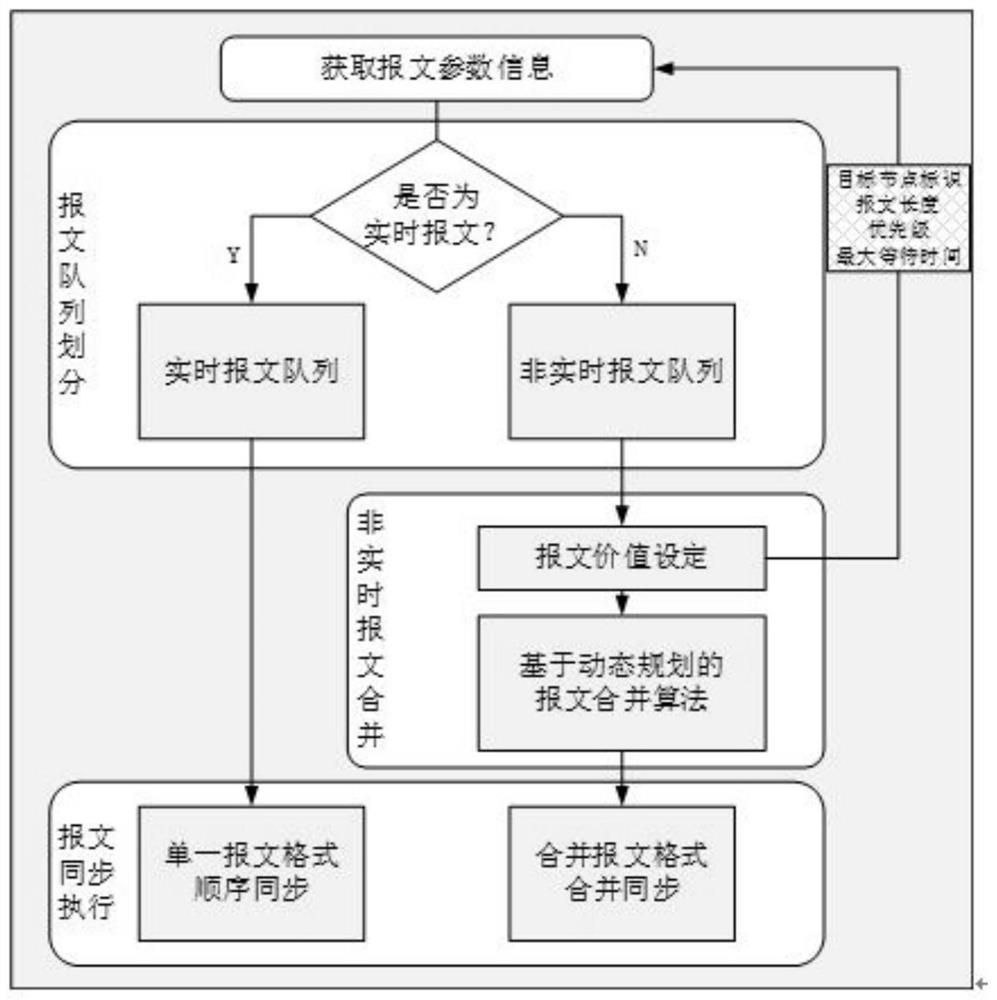

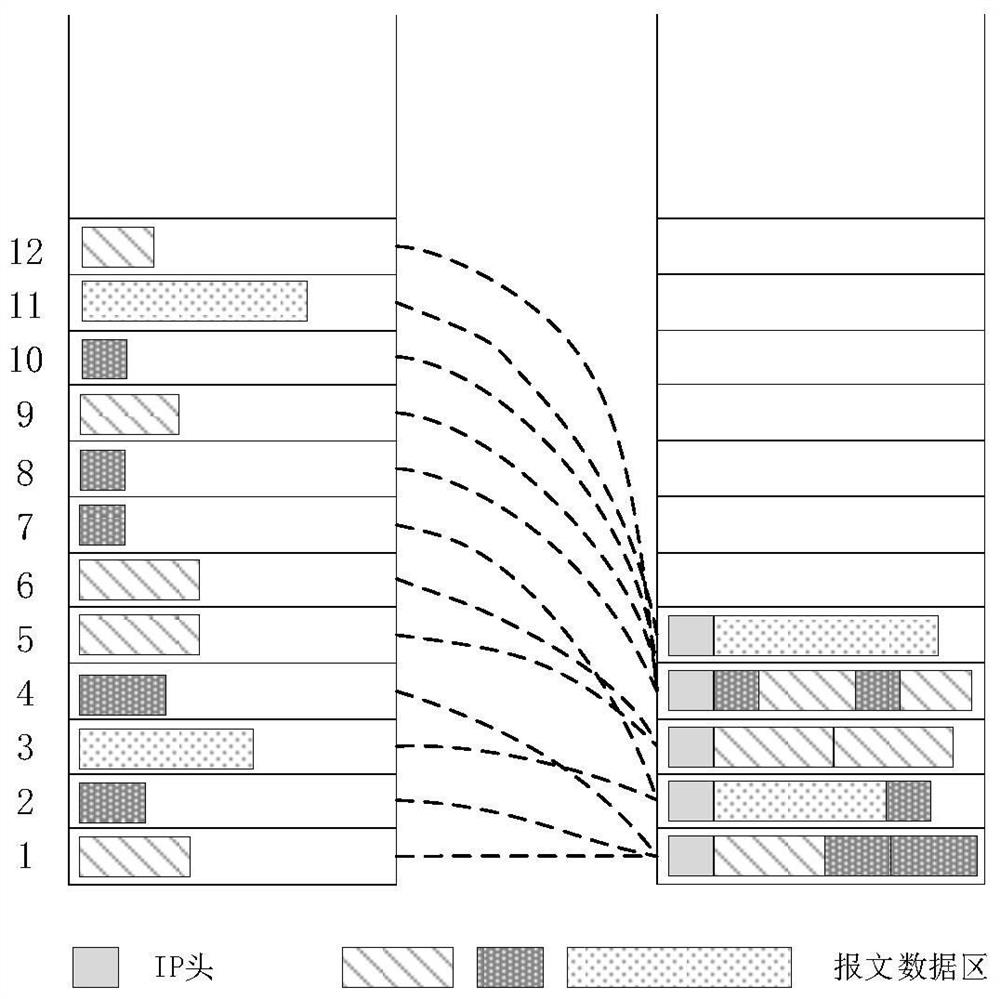

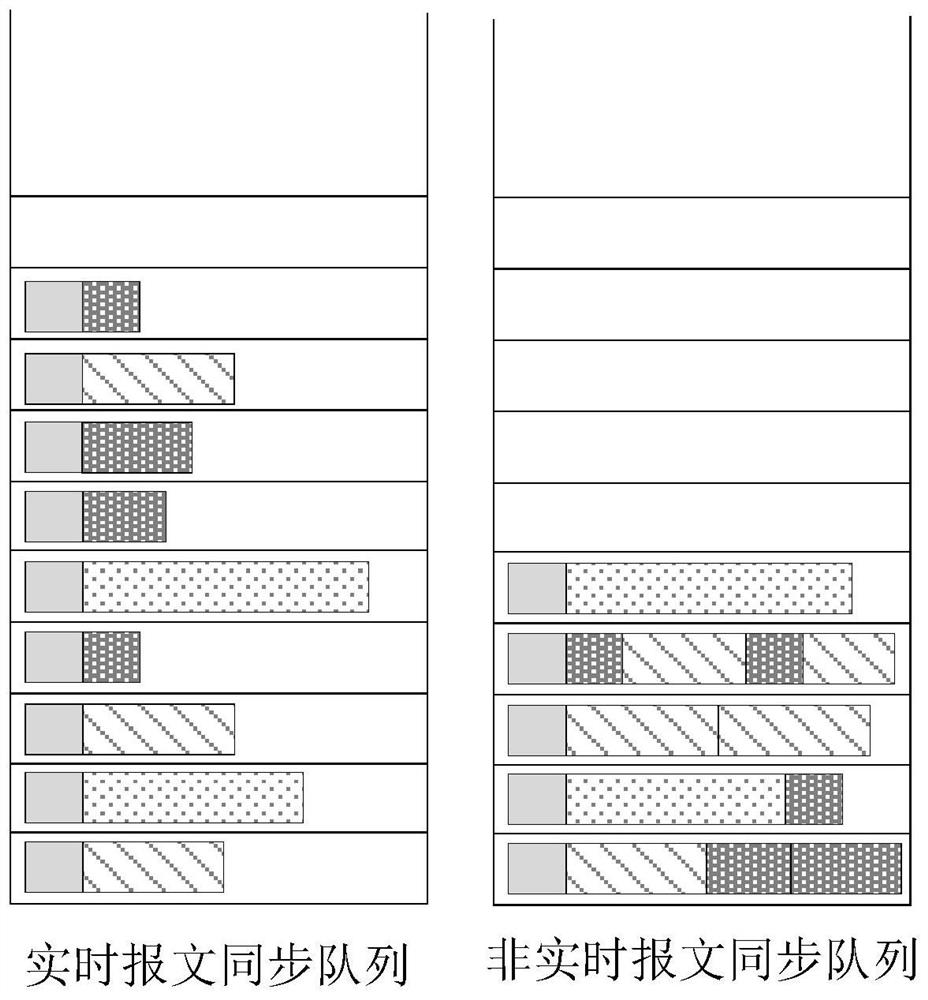

Data message-oriented double-queue synchronization method, system and device, and storage medium

ActiveCN112737978AProtection needsReduce overheadData switching networksHigh level techniquesMessage queueTime delays

The invention discloses a data message-oriented double-queue synchronization method, system and device, and a storage medium, and the method comprises the following steps: obtaining message parameters, and dividing the message parameters into a real-time message queue and a non-real-time message queue according to the real-time demands of messages; storing the high-time-sensitivity message into a real-time message queue based on the time delay sensitive information identifier, and storing the low-time-sensitivity message into a non-real-time message queue; for non-real-time messages, combining a plurality of non-real-time messages into an IP message data area in a protocol preset mode by adopting a message combination algorithm based on dynamic planning according to message destination node identifiers and messages of the same destination node, and sharing an IP header, so that the corresponding non-real-time messages are combined and packaged; performing a combined message format synchronous execution strategy; and for the real-time message, completing a single message format synchronous execution strategy according to a real-time message generation time sequence. According to the invention, while the real-time message requirement is ensured, the synchronization frequency of non-real-time messages and the expenditure of an IP head are reduced through a message merging mode.

Owner:CHINA ELECTRONICS TECH GRP NO 7 RES INST

Control method for gear pre-selection for dual clutch transmission

The invention relates to control methods for dual clutch transmissions, particularly to a control method for gear pre-selection for an uncombined shaft of a dual clutch transmission and aims at providing the method capable of guaranteeing economy and dynamic property requirements of shift points as well as whole drivability and comfort of a whole vehicle. The control method mainly comprises the steps of judging gears to be combined on a target shaft according to the whole acceleration and the current operating gear; calculating time T required for arriving at actual shaft points of pre-selected gears; determining time T1 required for completing combination of the pre-selected gears according to the rotating speed of the target shaft; determining time T2 required for completely finishing the combination of the pre-selected gears by a synchronizer according to the position of the synchronizer; determining a safety time factor T3 according to the T1, adding the T2 and the T3 together, and if the sum is equal to the T, commanding the synchronizer to begin to execute combination of the pre-selected gears.

Owner:HEFEI CHANGAN AUTOMOBILE +1

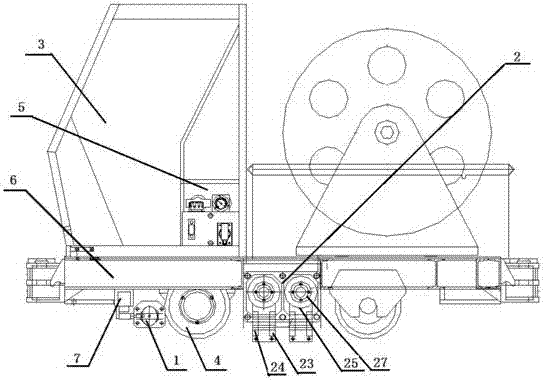

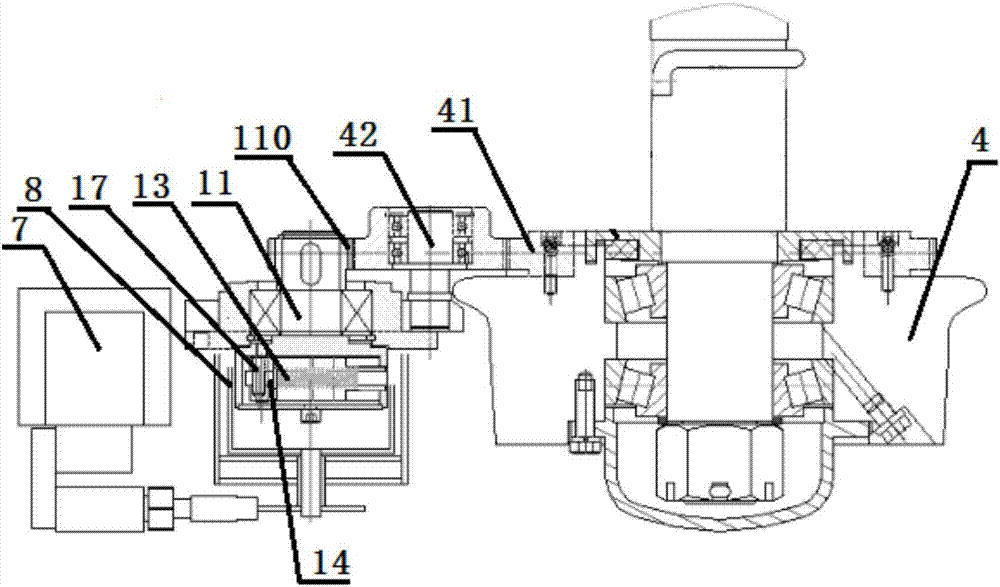

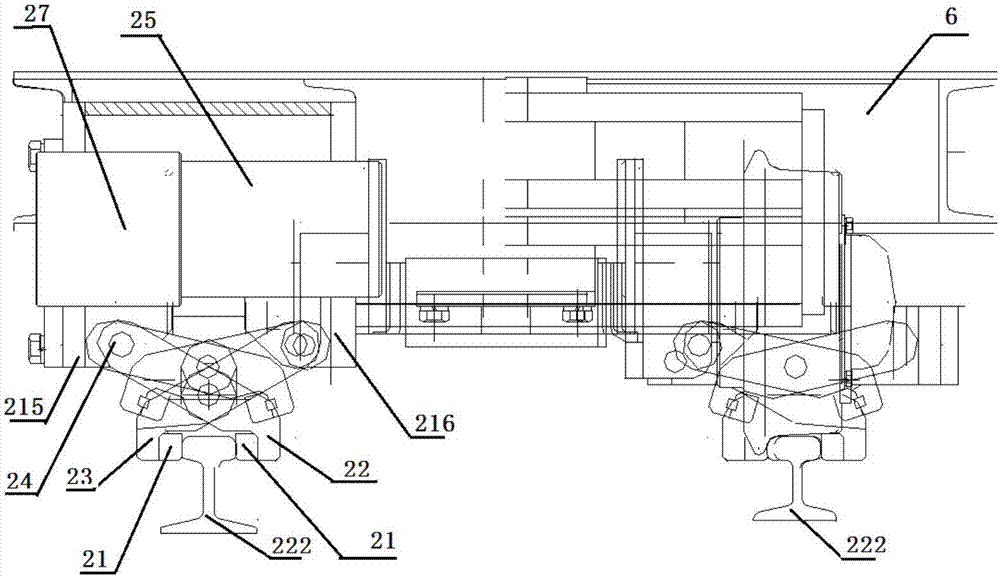

Novel brake shuttle vehicle system of mining endless rope winch

ActiveCN107150699AProtectiveFunctionalRailway hydrostatic brakesRailway hydrodynamic brakesAutomatic controlCommon rail

A novel brake shuttle vehicle system of a mining endless rope winch comprises a vehicle bridge, an operating room, a control box and a brake holding rail assembly, wherein the control room is fixedly connected with the vehicle bridge; the control box is arranged on the operating room and is used for controlling a hydraulic transmission pipeline system; the brake holding rail assembly is arranged at the bottom of the vehicle bridge. The novel brake shuttle vehicle system of the mining endless rope winch is characterized in that the brake holding rail assembly comprises an overspeed protection device, a hydraulic holding rail device and the hydraulic transmission pipeline system; the overspeed protection device is fixedly connected with the bottom of the vehicle bridge; a brake system has automatic protection and manual protection functions; a brake adopts pliers-type hydraulic holding rail brake, can be controlled manually and automatically, and is a fail safety type. During operation, brake pliers can be lifted off the rail surface, so the novel brake shuttle vehicle system is suitable for up-and-down common rail operation. During braking, pliers-type brake holds the two sides of the rail head, so the novel brake shuttle vehicle system is high in safety, high in reliability and worthy of large-scale application and popularization.

Owner:ZAOZHUANG UNIV

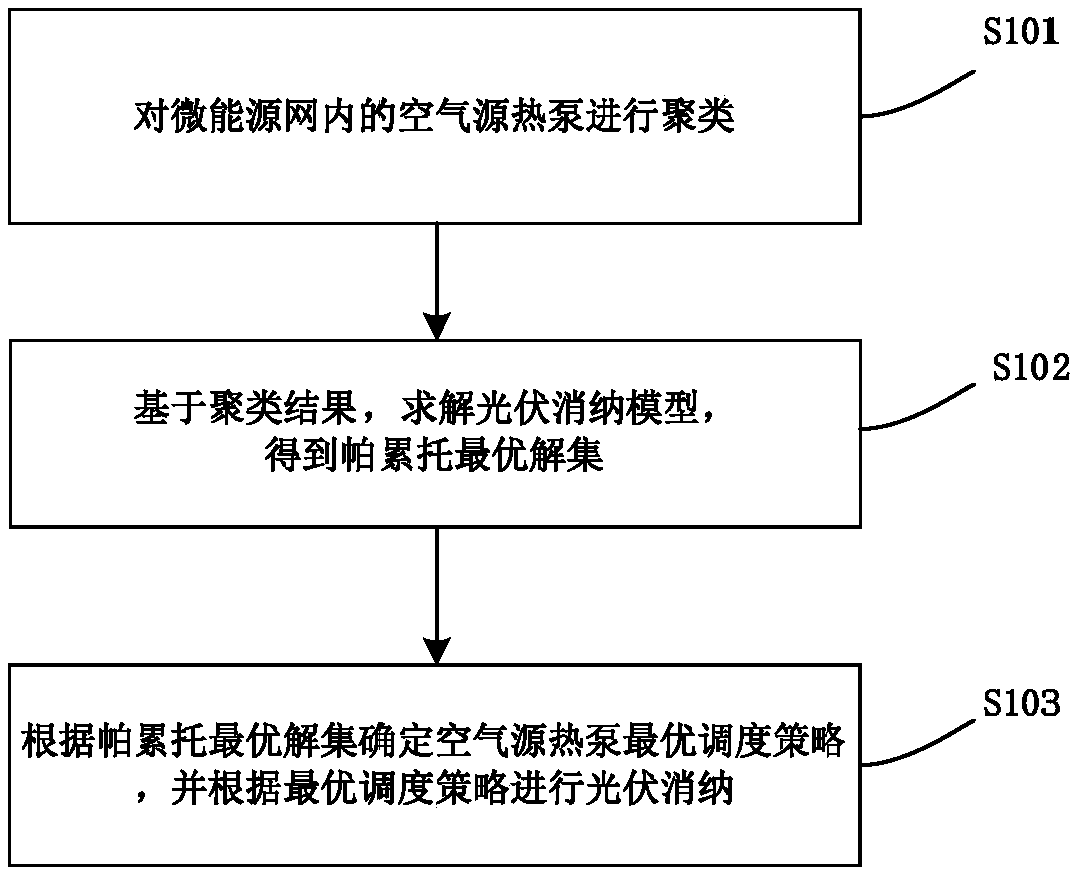

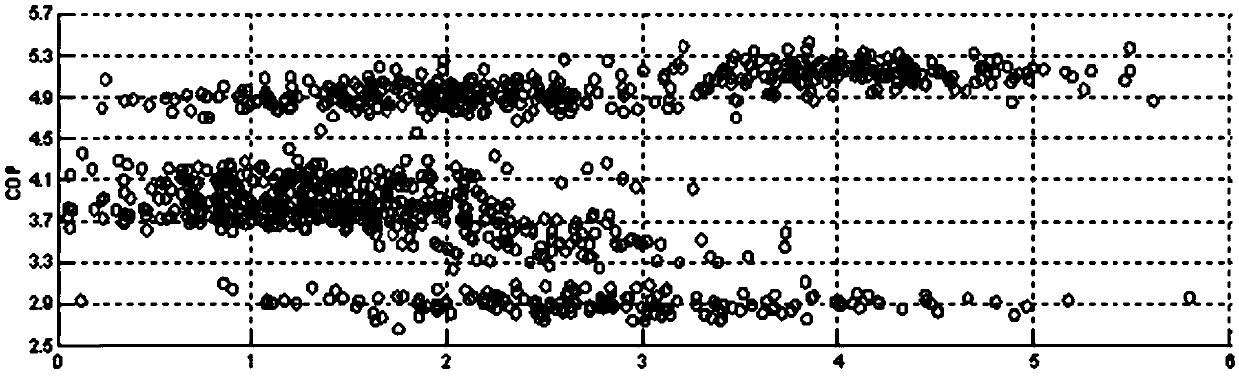

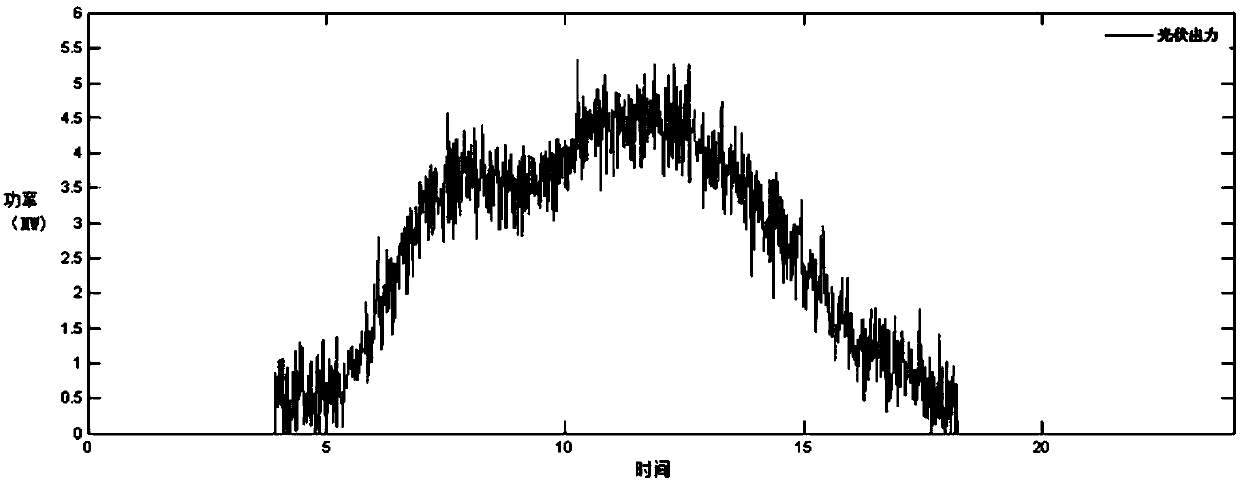

A method and apparatus for photovoltaic dissipation in a micro-energy grid

PendingCN109038645AIncrease profitIncrease the number ofSingle network parallel feeding arrangementsPhotovoltaic energy generationCombustionPower grid

The invention provides a method and apparatus for photovoltaic dissipation in a micro-energy network. Firstly, the air source heat pump in the micro-energy network is clustered, and then a pre-constructed photovoltaic dissipation model is solved based on the clustering result to obtain a Pareto optimal solution set. Finally, the optimal dispatching strategy of air source heat pump is determined, and the photovoltaic energy dissipation is carried out, which improves the utilization rate of air source heat pump in the micro-energy network. The photovoltaic energy dissipation is large, and the number of air source heat pumps that can be dispatched is increased. At the same time, the heat demand and the heating cost of the us are ensured, By clustering the air source heat pumps with differentparameters, the scheduling of air-source heat pumps is transformed into the scheduling of air-source heat pump clusters, As a result, the difficulty of the dispatch algorithm is simplify, the light abandonment phenomenon in the micro-energy network during the peak period of the photovoltaic power generation is reduced, the energy waste is reduced, the peak-shaving capacity of the micro-energy network is increased, the safety and stability of the large power network can be ensured, the energy and heating cost are saved, the heating quality is improved, and the pollution gas generated by coal combustion is reduced.

Owner:CHINA ELECTRIC POWER RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com