Novel heat energy circulation Chinese frying furnace device

A heat energy, Chinese-style technology, which is applied in the field of new-type heat-energy cycle Chinese-style frying furnace devices, can solve problems such as exhaust gas emission pollution, and achieve the effects of solving emission pollution, saving gas, and safe and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

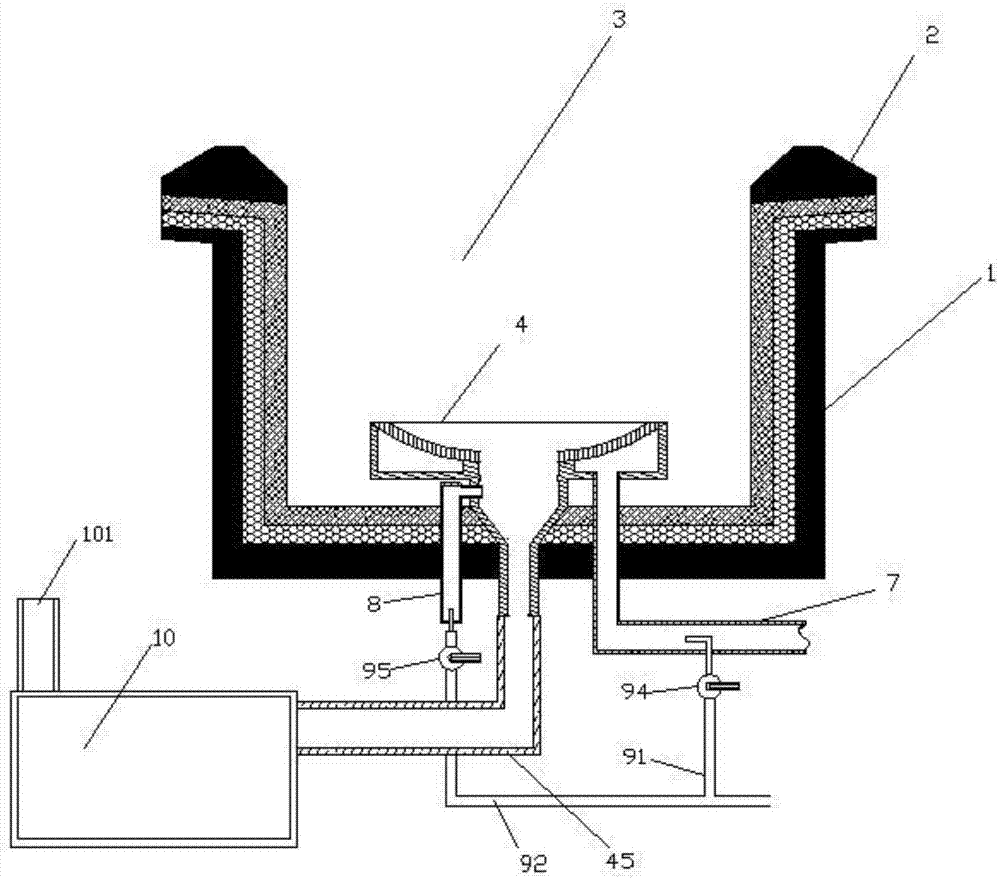

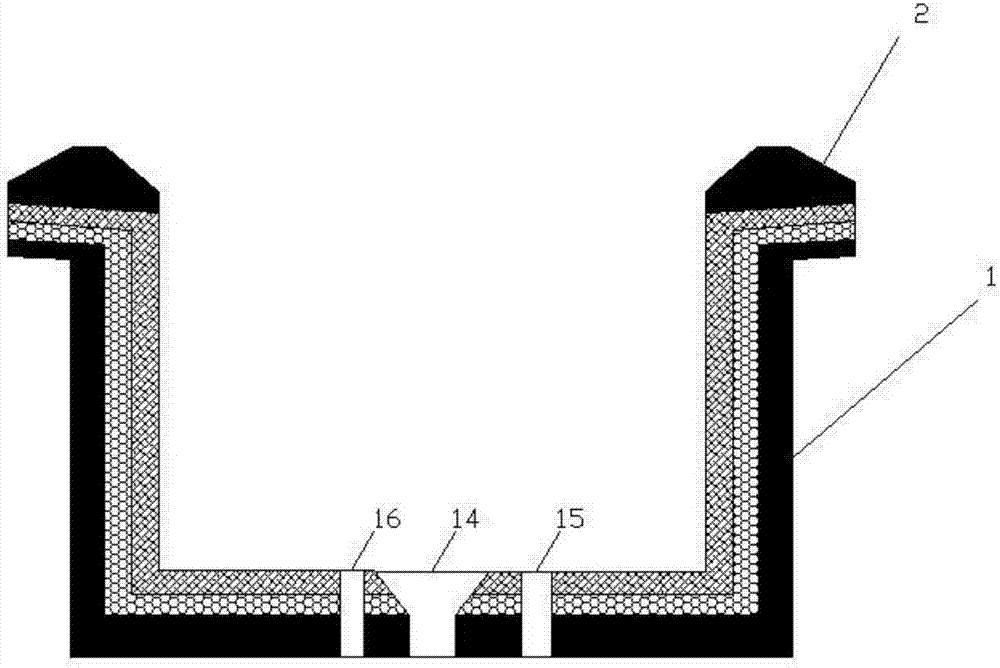

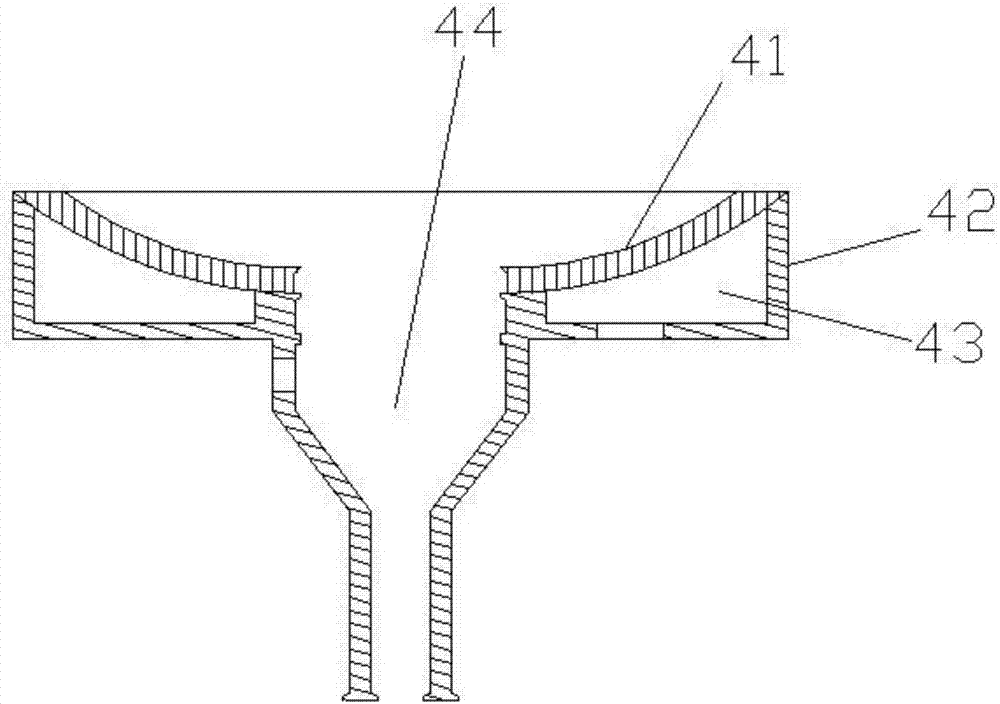

[0041] see Figure 1~3 , the present invention provides a technical solution:

[0042] A new type of thermal energy circulation Chinese frying furnace device, including a burner 4, a furnace 3, a furnace shell 1 and a wok support 2, the burner 4 includes a combustion plate 41, a burner support 42 and a gas mixing chamber 43, the combustion The plate 41 is located on the burner support 42, the middle part of the burner 4 is provided with a waste gas port 44, the upper part of the furnace shell 1 is provided with a wok support 2, and the center of the bottom of the furnace shell 1 is provided with a first installation hole 14, The burner 4 is located in the furnace 3, the bottom of the burner 4 is located in the first installation hole 14, the bottom of the furnace shell 1 is also provided with a second installation hole 15 and a third installation hole 16, the second installation The air-air mixing pipe 7 is arranged in the hole 15, and the air-air mixing pipe 7 is connected w...

Embodiment 2

[0044] see Figure 3-5 , the present invention provides a technical solution:

[0045]A new type of thermal energy circulation Chinese frying furnace device, including a burner 4, a furnace 3, a furnace shell 1 and a wok support 2, the burner 4 includes a combustion plate 41, a burner support 42 and a gas mixing chamber 43, the combustion The plate 41 is located on the burner support 42, the middle part of the burner 4 is provided with a waste gas port 44, the upper part of the furnace shell 1 is provided with a wok support 2, and the center of the bottom of the furnace shell 1 is provided with a first installation hole 14, The burner 4 is located in the furnace 3, the bottom of the burner 4 is located in the first installation hole 14, the bottom of the furnace shell 1 is also provided with a second installation hole 15 and a third installation hole 16, the second installation The air-air mixing pipe 7 is arranged in the hole 15, and the air-air mixing pipe 7 is connected wi...

Embodiment 3

[0047] see Figure 6 ~ Figure 8 , the present invention provides a technical solution:

[0048] A new type of thermal energy circulation Chinese frying furnace device, including a burner 4, a furnace 3, a furnace shell 1 and a wok support 2, the burner 4 includes a combustion plate 41, a burner support 42 and a gas mixing chamber 43, the combustion The plate 41 is located on the burner support 42, the middle part of the burner 4 is provided with a waste gas port 44, the upper part of the furnace shell 1 is provided with a wok support 2, and the center of the bottom of the furnace shell 1 is provided with a first installation hole 14, The burner 4 is located in the furnace 3, the bottom of the burner 4 is located in the first installation hole 14, the bottom of the furnace shell 1 is also provided with a second installation hole 15 and a third installation hole 16, the second installation The air-air mixing pipe 7 is arranged in the hole 15, and the air-air mixing pipe 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com