High compression ratio spark-ignition type engine

A technology of spark ignition and high compression ratio, which is applied to combustion engines, internal combustion piston engines, engine control, etc., can solve the problems of low fuel economy, compression ratio not exceeding 13, and low compression ratio, so as to ensure oxygen supply, Effects of suppressing knocking and increasing intake pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

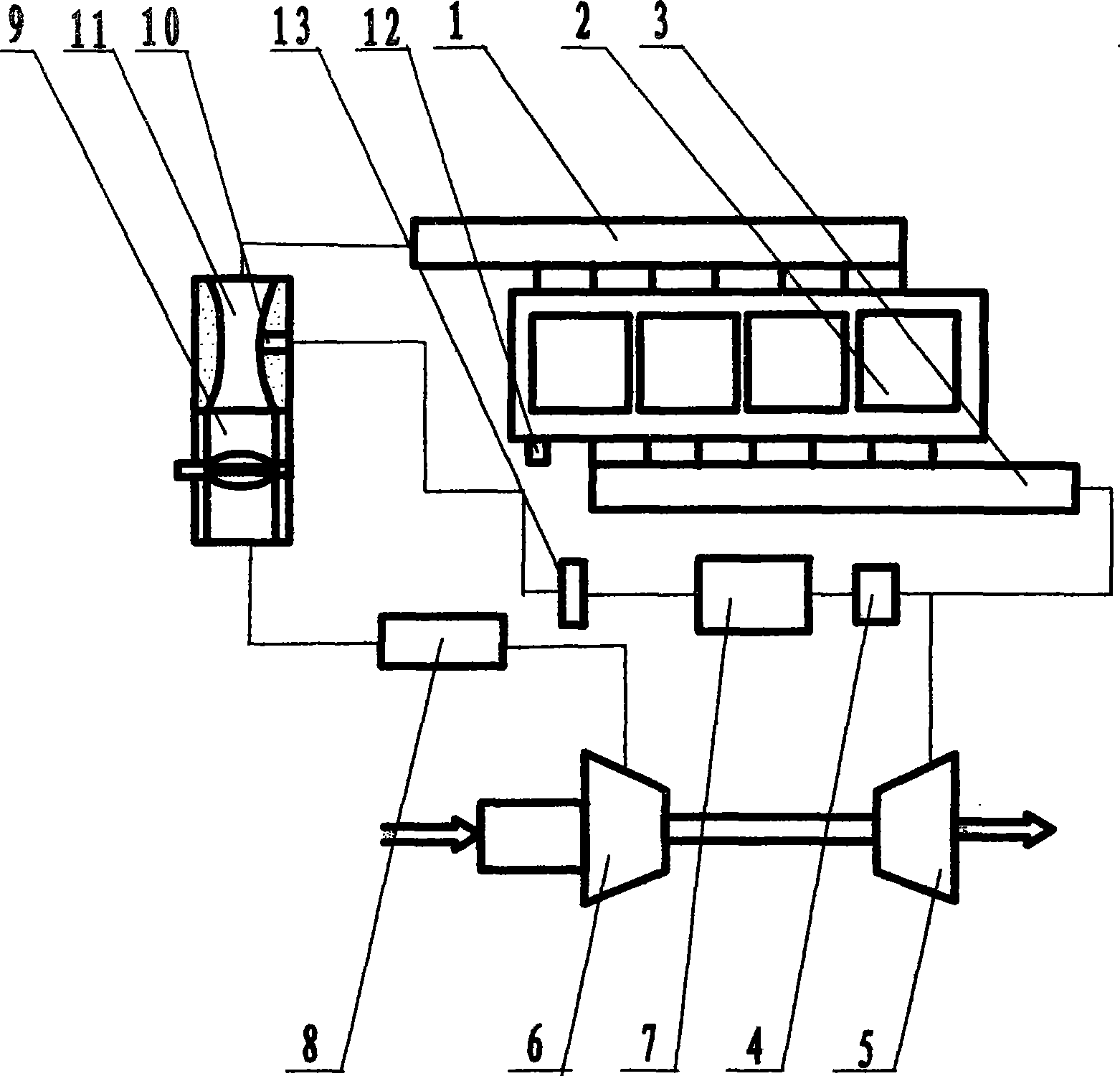

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Referring to the accompanying drawings, a high compression ratio spark ignition engine of the present invention includes a cylinder block 2, an intake manifold 1 and an exhaust manifold 3, and the end of the exhaust manifold 3 is connected with an exhaust gas worm gear 5 and an EGR valve 4 . The front end of the intake manifold 1 is connected with a Venturi tube 11, and the front end of the Venturi tube 11 is connected with the intake throttle 9, and the turbo compressor 6 is connected with the intake throttle 9 through the intake intercooler 8. There is a measuring hole 10 in the middle of the Venturi pipe 11 which communicates with the lumen, and the EGR valve 4 is connected to the measuring hole 10 through the EGR cooler 7 . Since the exhaust gas after methanol combustion contains a large amount of water, after the exhaust gas passing through the EGR valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com