Double-circulation type overhead heat pipe micro-module

A micro-module, dual-circulation technology, applied in household heating, heating methods, household heating and other directions, can solve the problems of occupying cabinet space, wasting computer room area, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

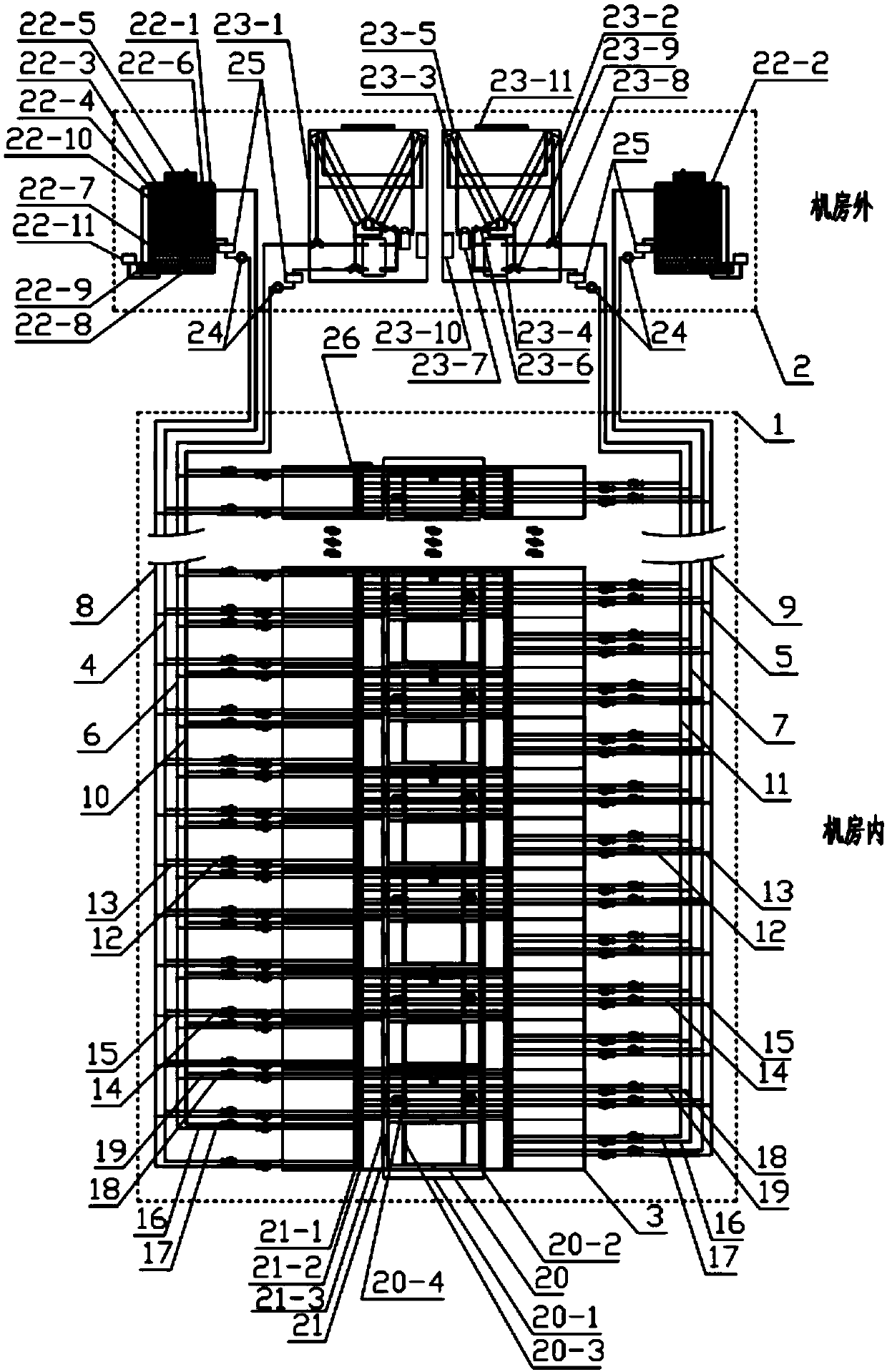

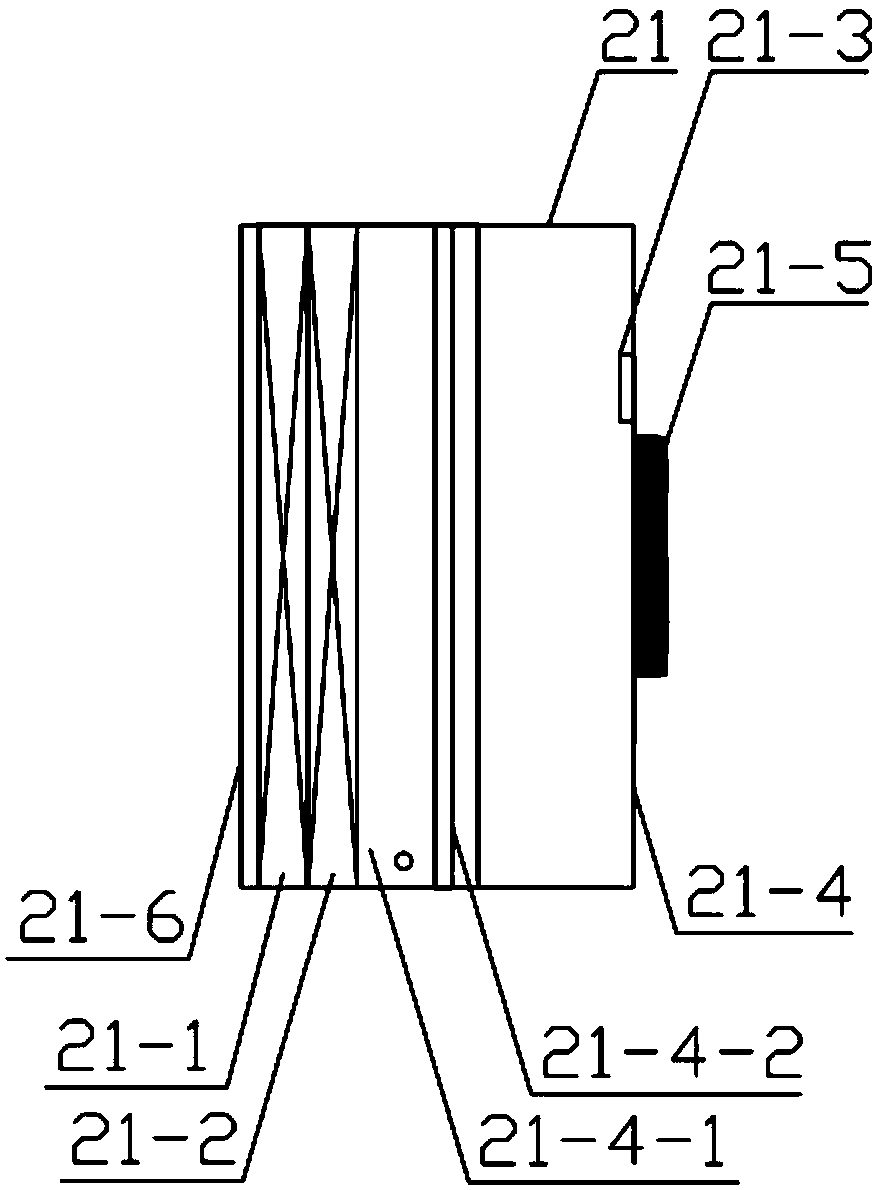

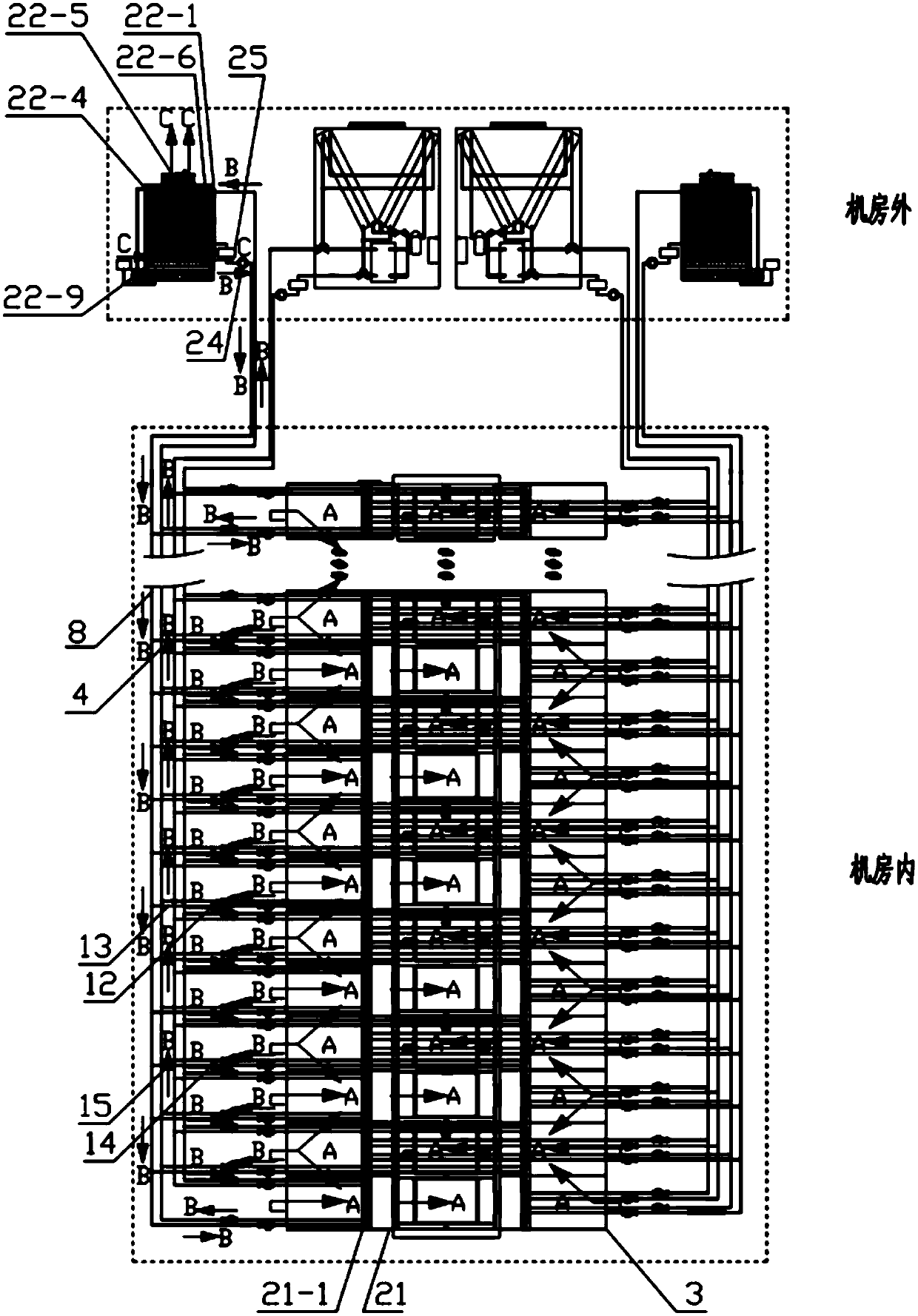

[0046] figure 1It is a structural schematic diagram of the dual-circulation overhead heat pipe micro-module of the present invention. The double-circulation overhead heat pipe micromodule of the present invention includes an indoor closed channel module 1 and an outdoor cooling unit 2, and the indoor closed channel module 1 includes at least two rows of server cabinets 3 arranged oppositely, and air collecting pipes I4, air collecting pipe II5, and air collecting pipes. Ⅲ6, gas collection pipe Ⅳ7, liquid pipe Ⅰ8, liquid pipe Ⅱ9, liquid pipe Ⅲ10, liquid pipe Ⅳ11, air pipe outlet pipe Ⅰ12 with inspection valve, liquid pipe inlet pipe Ⅰ13 with inspection valve, air pipe with inspection valve Outlet pipe II14, liquid pipe inlet pipe with inspection valve I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com