Small-cylinder-diameter-ratio pipe connector submerged arc saddle-shaped automatic welding method

A saddle-shaped and pipe joint technology, which is applied in arc welding equipment, welding equipment, tubular objects, etc., can solve problems such as welding defects on the surface of the weld, achieve stable performance, beautiful weld shape, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] For ease of understanding, the present invention will be explained in detail below in conjunction with the accompanying drawings and specific embodiments.

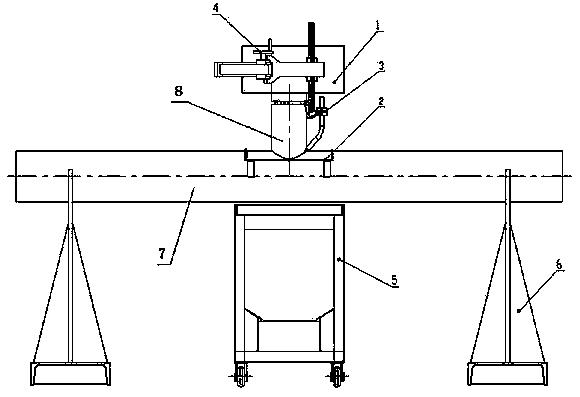

[0018] An automatic submerged arc saddle-shaped welding method for pipe joints with a small cylinder diameter ratio, the steps are as follows: figure 1 As shown, the cylinder 7 is set on the welding support 6, the pipe joint 8 is vertically fixed on the cylinder 7 by manual argon arc welding, and the flux protection tool 2 is placed on the cylinder 7 to support the welding For the required flux, use a balance crane to place the submerged arc saddle automatic welding machine 1 on the pipe joint 8, and extend the three-jaw chuck on the submerged arc saddle automatic welding machine 1 into the inside of the pipe joint 8 to make the submerged arc saddle The automatic welding machine 1 is fixed on the pipe joint 8, and through the adjustment of the saddle drop regulator 4 and the welding torch angle regulating valve 3 re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com