Flute-shaped current equalizer applied for uniformly distributing two-phase flow of header branch pipe

A technology of uniform distribution and branch pipes, which is applied in the direction of heat exchanger shells, lighting and heating equipment, heat exchange equipment, etc., can solve the problem of limited two-phase flow distribution effect of radial inlet header branch pipes, increased system pressure drop, Uneven distribution and other problems can be achieved to improve the two-phase flow distribution characteristics, simple installation, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

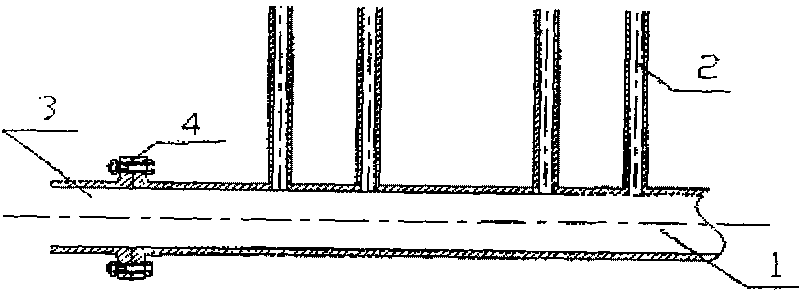

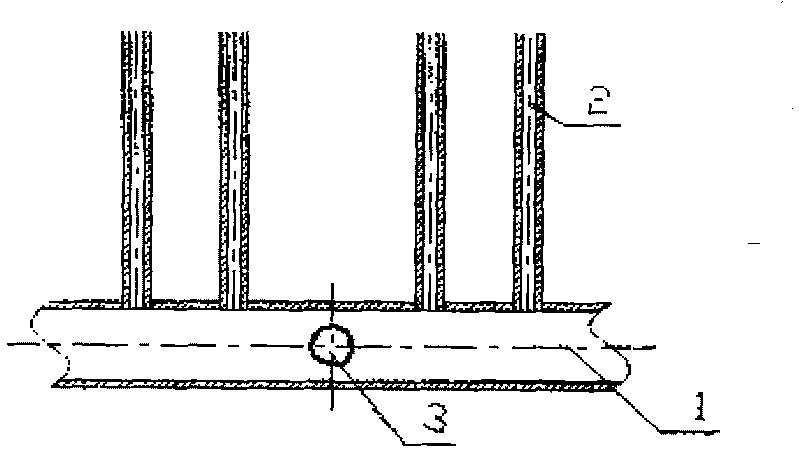

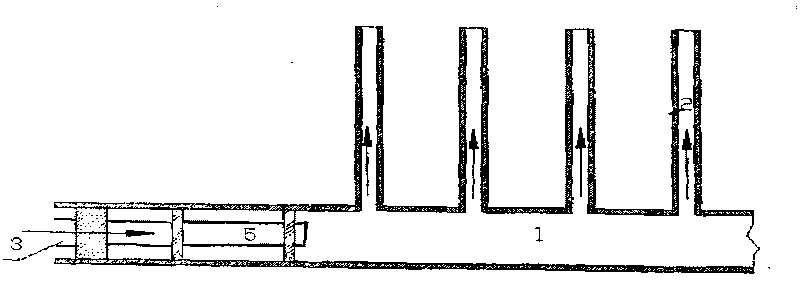

[0017] The invention provides a flute-shaped flow equalizer applied to the uniform distribution of two-phase flow in the branch pipe of the header. The invention will be described below with reference to the accompanying drawings.

[0018] exist Figure 4a The structure diagram and Figure 5a As shown in the structural diagram of the header system using the axial introduction of the internal flow equalizing bellows pipe, a concentric bellows pipe 6 is installed inside the header main body 1, and the introduction pipe 3 is introduced from the radial direction of the header main body 1 to connect with the bellows pipe connection (such as Figure 4a , Figure 4b , Figure 4c shown), or from the axial introduction of the header body 1 to connect with the piccolo tube (such as Figure 5a , Figure 5b shown); to make the flow distribution of the two-phase fluid inside the main body of the header uniform. The position of the opening 7 of the flute pipe 6 corresponds to the entr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com