Large-scale turning axle verticality detection device and method

A technology of detection device and rotary axis, which is used in measurement devices, surveying and navigation, measurement of inclination, etc., can solve the problems of high difficulty, danger and low efficiency of work, reduce work intensity and danger, and increase work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

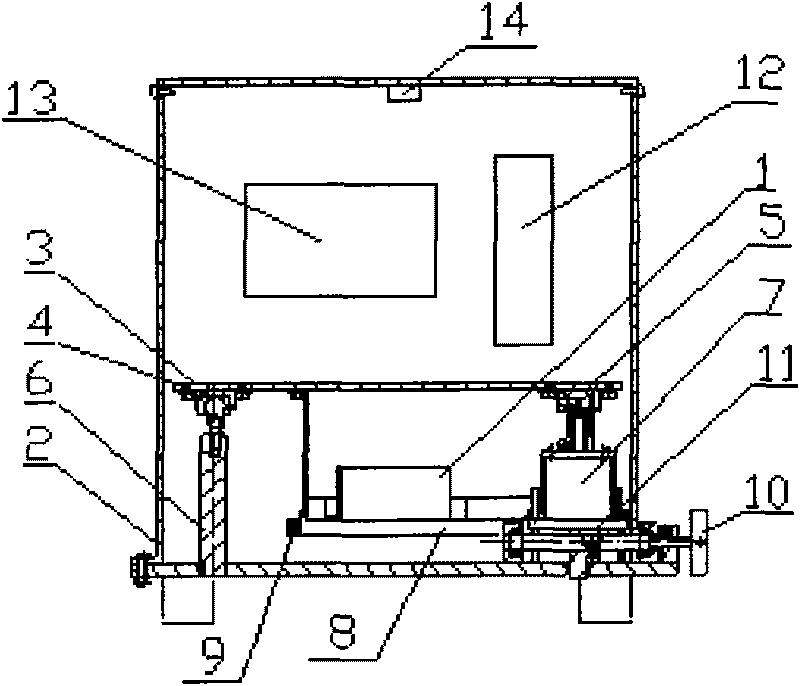

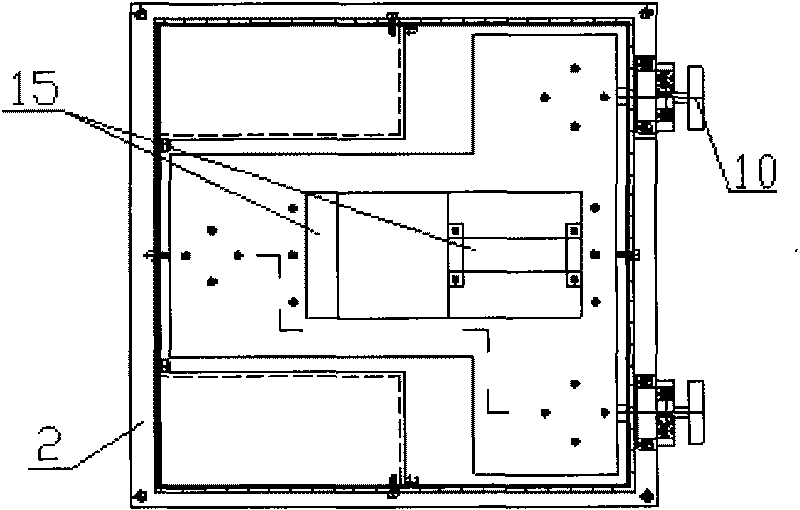

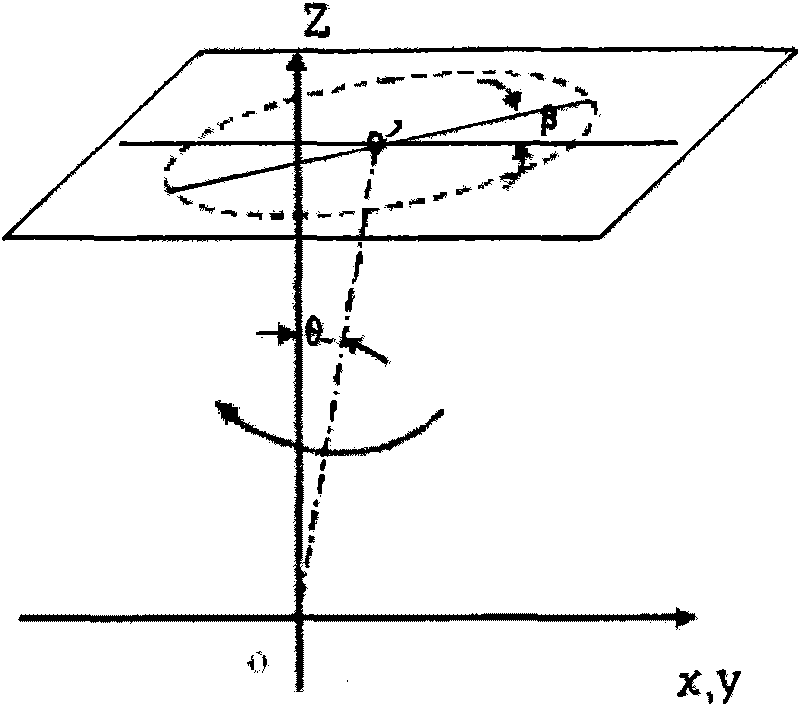

[0019] Such as figure 1 , figure 2 shown. The large-scale rotating shaft verticality detection device includes an electronic level 1, and the electronic level 1 is placed in the detection box 2. The detection box 2 is sealed. The detection box 2 is equipped with an LED light source, and the detection box 2 is equipped with an adjustable platform 3. The adjustable platform 3 is provided with one or more bubble levels 15, the left and right bottoms of the adjustable platform 3 are respectively provided with fulcrums 4, 5, and one end of the support rod 6 is fixed on the bottom of the detection box 2, and the other end is connected to the adjustable platform 3. The fulcrum 4 at one end of the bottom is hinged (using a universal joint structure), and there are two fulcrums 5 at the bottom of the right end of the adjustable platform. The end of the output shaft is threadedly connected with the fulcrum 5 above it respectively, the level platform 8 is rigidly connected with the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com