Liquid density measurement device and measurement method

A liquid density and measuring device technology, which is applied in the direction of material analysis by measuring buoyancy, can solve the problems of low measurement accuracy, complex structure, poor stability, etc., and achieve the effect of low cost, small volume and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

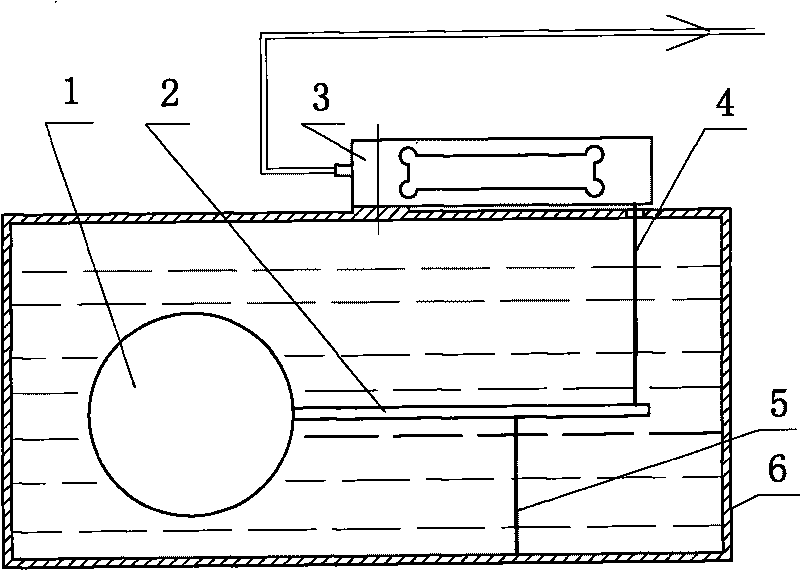

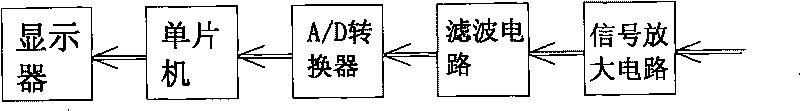

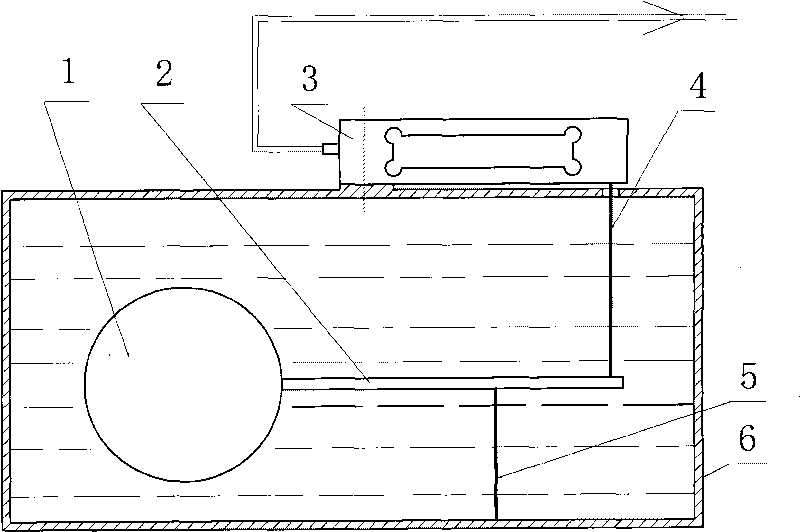

[0027] The liquid density measuring device is composed of hardware and software. The hardware part includes a force sensor 3, a control unit, a container 6, a float 1 installed in the container 6, a lever 2, a fulcrum cable 5 and a force-measuring cable 4; The force sensor 3 is located above the container 6 and is fixedly connected to the container 6. The force sensor 3 is a commercially available finished product, and the output end of the force sensor 3 is connected to the corresponding terminal of the control unit through a wire. The force-measuring guy wire 4 is arranged in the container 6, the upper end of the force-measuring guy wire 4 is fixedly connected with the force-measuring end of the force sensor 3, the lower end of the force-measuring guy wire 4 is fixedly connected with one end of the lever 2, and the other end of the lever 2 is connected with the float 1 Fixedly connected; the upper end of the fulcrum stay wire 5 is fixedly connected with the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com