Filter stick bonding strength detector and use method

A bonding strength and detection instrument technology, applied in the direction of instruments, measuring devices, mechanical devices, etc., to achieve the effect of convenient operation, reasonable and practical structure design, accurate and effective detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The filter rod bond strength tester applies a certain load to the end of the filter rod for a period of time, and uses whether the filter element is pushed out as the judgment standard.

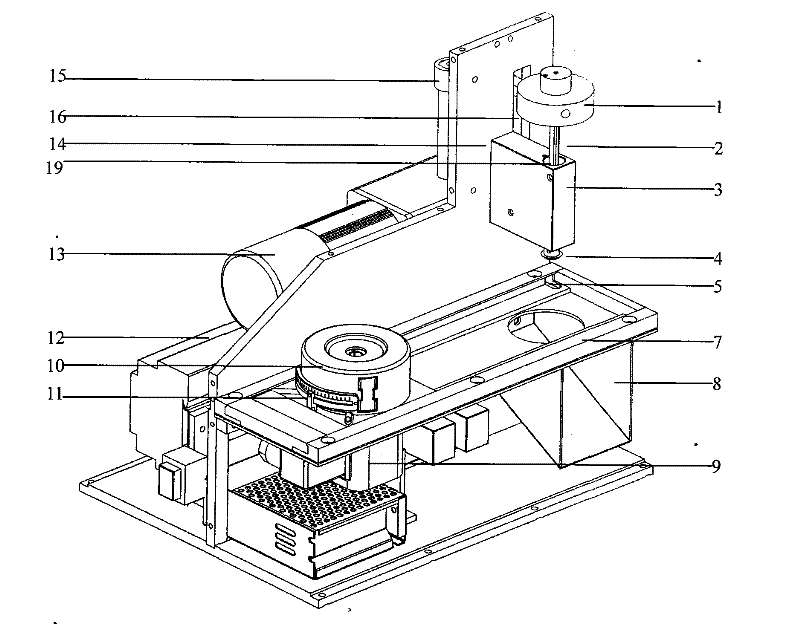

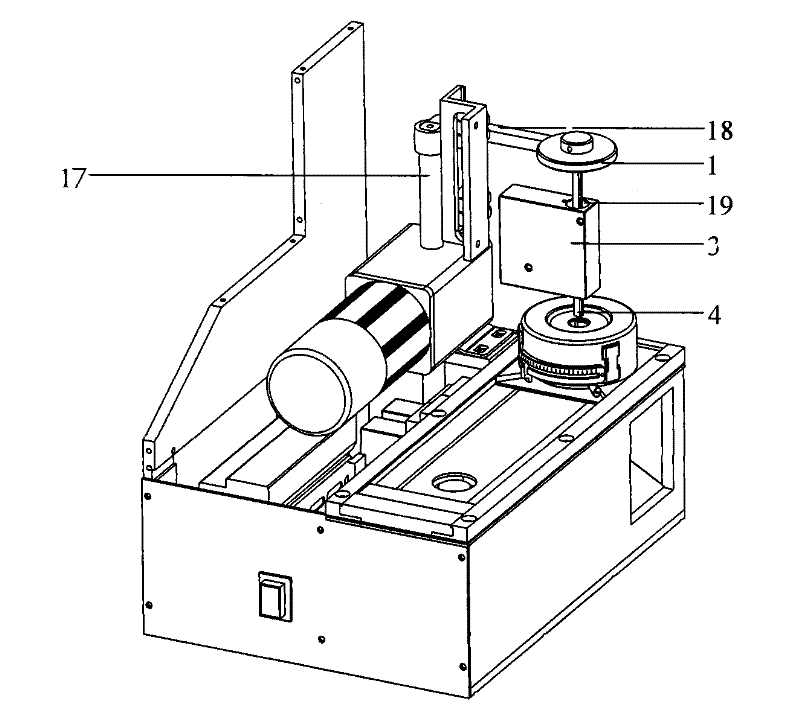

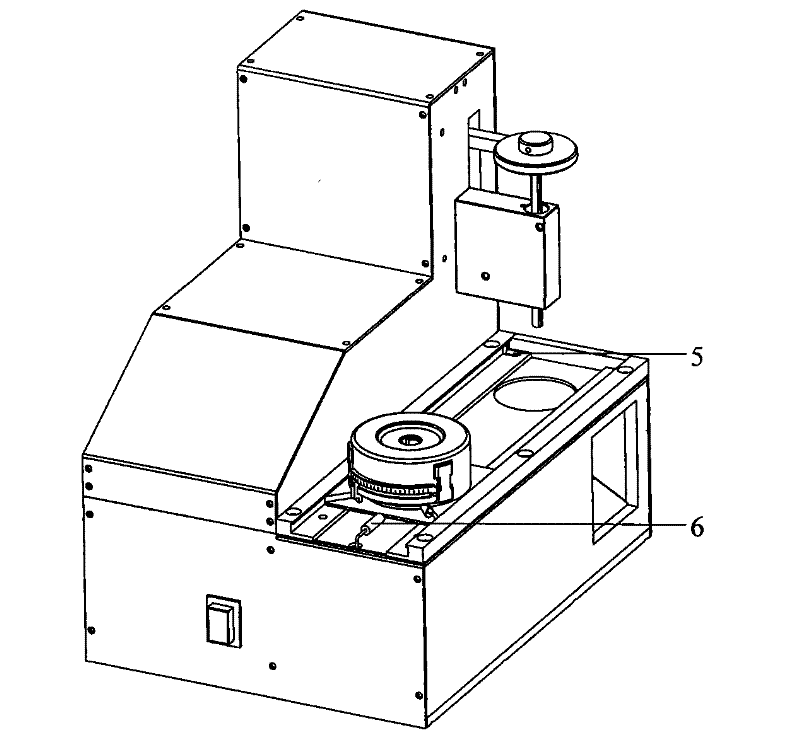

[0034] See Figure 1~3 , the instrument includes a workbench, a guide rail 7 is set on the workbench, and a clamp 10 for clamping a filter rod (sample) is set on the guide rail 7. The guide rail 7 includes a filter rod loading position end and a filter rod testing position end, and the clamp 10 can move back and forth between the two ends along the guide rail 7 . The filter rod is placed in the center of the clamp 10, see Figure 6 , so that the three-legged jaws shrink toward the center at the same time, and the filter rod can be clamped. Preferably, the front end surface of each jaw is a concave arc surface, so it is in surface contact with the filter rod, which can ensure a good clamping effect. There is an indicating dial 11 on the clamp 10, and a movable and lockable positionin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com