Automatic control method for feeding deviation

A technology of deviation and deviation range, applied in the field of production material feeding management system, to avoid human error, ensure correctness, and reduce the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

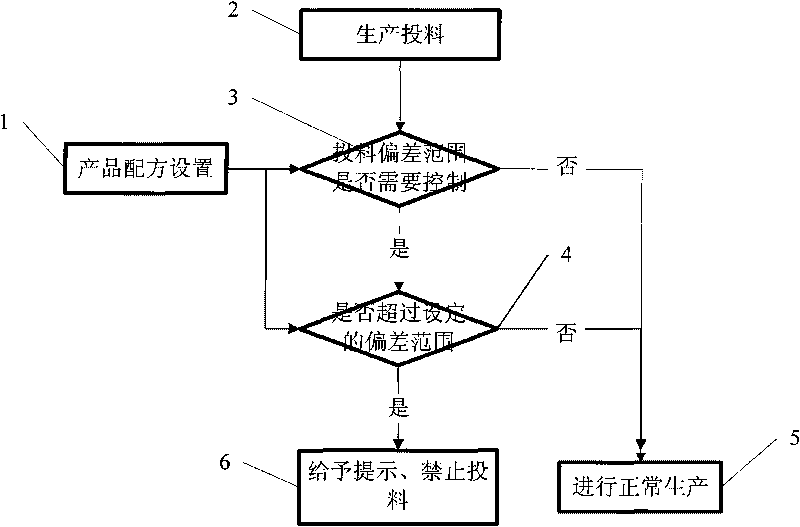

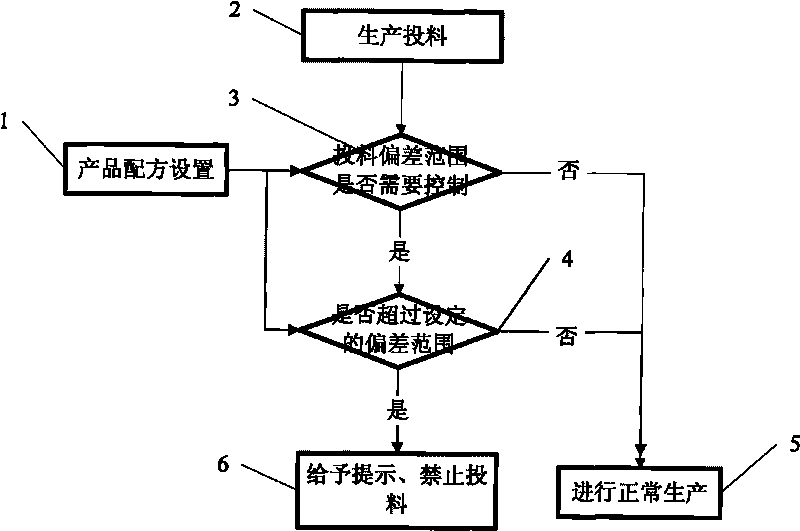

[0015] Such as figure 1 As shown, in the feeding deviation automatic control system, step 1 is the initial step, product formula setting; in step 2, start production and feeding; in step 3, the system automatically confirms whether the feeding deviation range of the material needs to be controlled, if not , then skip to step 5; if the conclusion of step 3 is yes, then in step 4, the system again determines whether the feeding amount of the material exceeds the tolerance range, if yes, then skip to step 6; if the conclusion of step 4 If no, then in step 5, the production can go on normally; in step 6, the system gives a prompt and prohibits feeding.

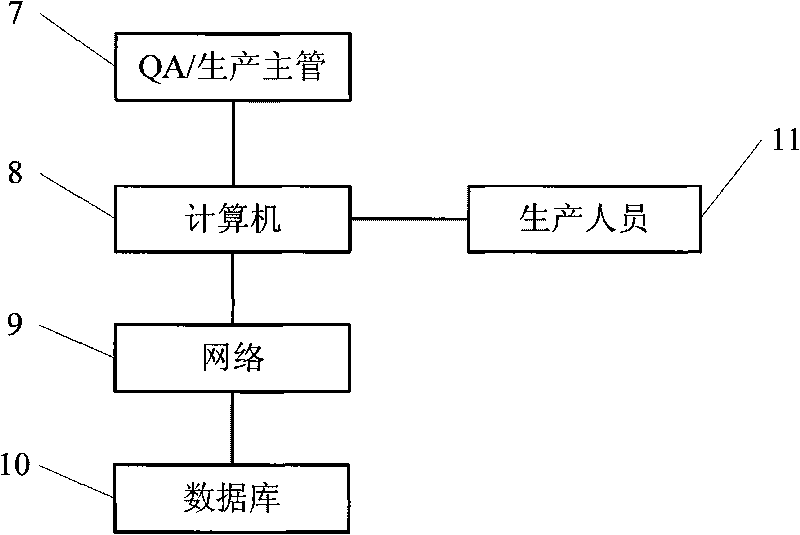

[0016] Such as figure 2 As shown, the figure 2 It is a schematic diagram of the main structure of the feeding deviation automatic control system of the present invention, and its structure inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com