Coil forming method and forming mould for electromagnetic metering equipment

A metering equipment and coil forming technology, applied in coils, coil manufacturing, circuits, etc., can solve problems such as difficulty in ensuring coil dimensional accuracy, large coil magnetic flux leakage, and irregular arrangement, and achieve easy control of processing technology and discrete magnetic flux The effect of reducing and neatly aligning the coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

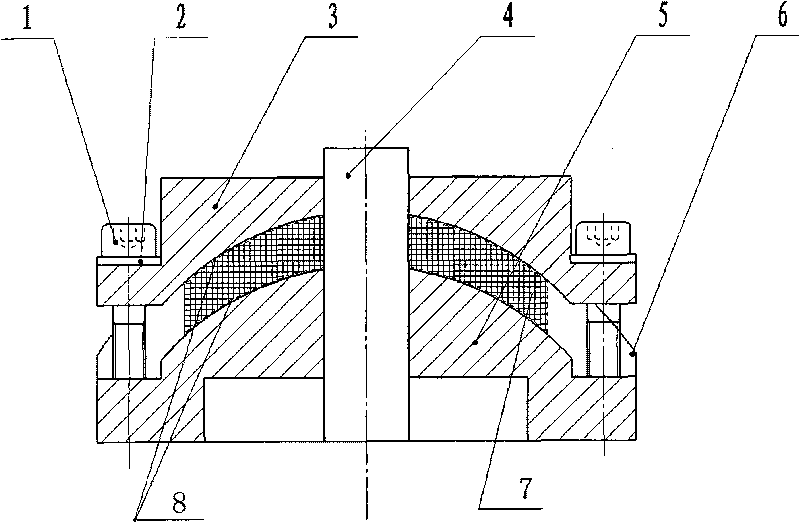

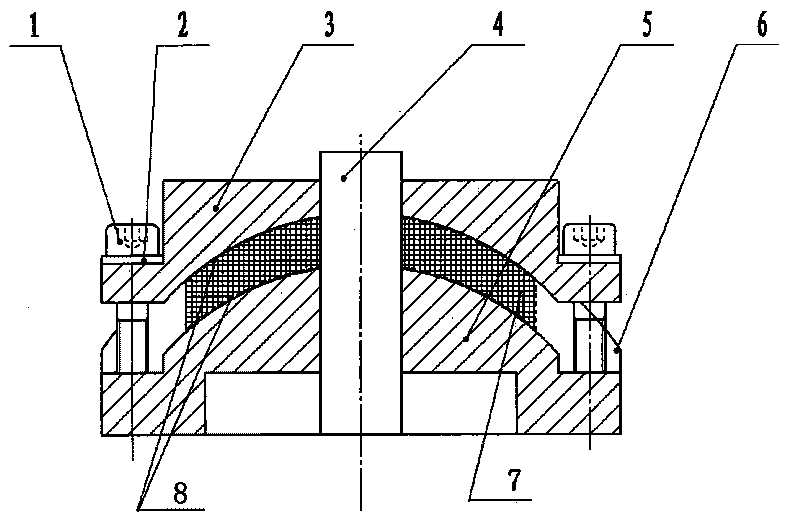

[0016] see figure 1 , a forming mold used for coil forming of electromagnetic metering equipment, the upper mold 3 is a concave mold with an upwardly concave cavity, and the lower mold 5 is a convex mold arc with an upwardly protruding cavity, and the radian of the cavity is the same as that of the end face of the coil mold. The bottom surface of the lower mold cavity is provided with a plane extending from the lower two ends, and a stop block 6 fixed with bolts on the plane, wherein the height of the stop block is equal to the thickness of the coil, is used to limit the position of the coil installed in the mould. The mold and the lower mold are fixed by screws 1, and the upper and lower molds are fixed and compressed. Liner 7 and pass patrix and counterdie and its gap cooperation.

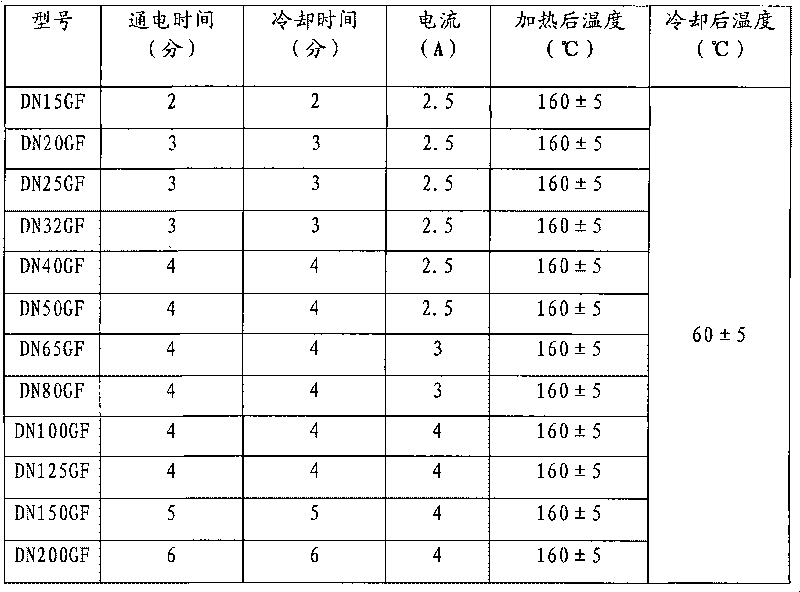

[0017] When forming coils for electromagnetic metering equipment, first install the winding die on the automatic winding machine and fix it securely. Adjust the parameters of the winding machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com