Alarm type thermal fuse-link

A technology of thermal fuses and fuses, which is applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve the problems of increasing the complexity of electrical equipment, failing to output alarm signals, unfavorable circuit reliability, etc. The effect of improving reliability and reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

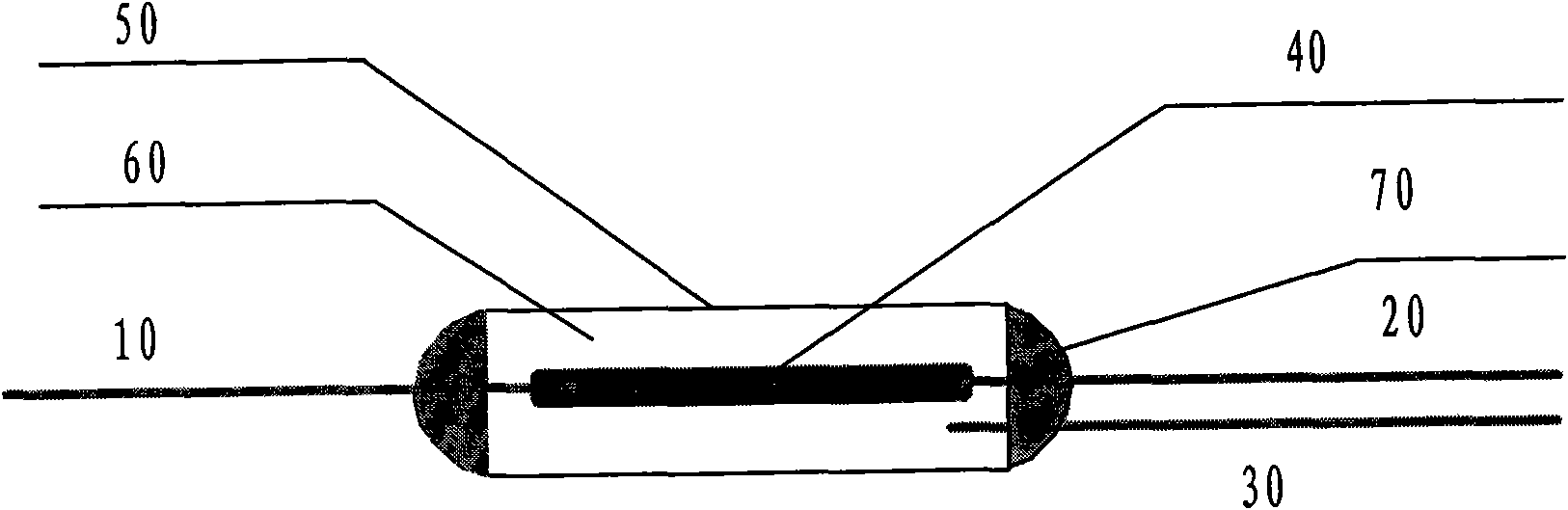

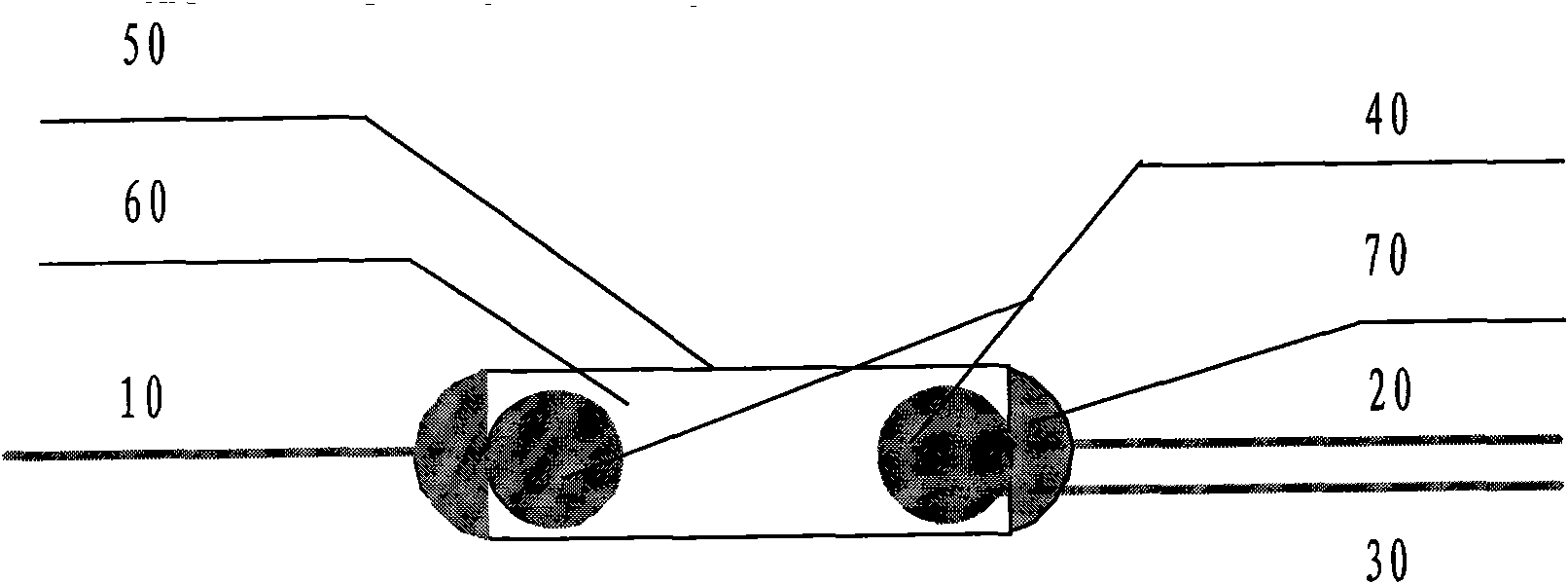

[0029] A preferred structure of the alarm type thermal fuse of the present invention is given in the embodiment, as figure 1 As shown, it includes: a casing 50 formed by sintering ceramics, an alarm electrode 30 fixed in the casing 50, a first electrode 10, a second electrode 20, and an alloy fuse 40 connecting the first electrode 10 and the second electrode 20; The alarm electrode 30 is adjacent to the first electrode 10 or the second electrode 20, and is used to weld the alloy fuse 40 with the alarm electrode 30 after fusing and shrinking and reuniting; the alloy fuse 40 is wrapped around to help Shrinkage agent 60. Epoxy resin sealing compound 70 is provided at both ends of the housing 50 , and the first electrode 10 , the second electrode 20 and the alarm electrode 30 are packaged and fixed by the epoxy resin sealing compound 70 and drawn out. The first electrode 10 and the second electrode 20 are fuse electrodes, preferably, the material of the fuse electrodes is copper....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com