Electromagnetic-coupling excitation speed regulator

A technology of electromagnetic coupling and governor, applied in asynchronous induction clutches/brakes, electrical components, electromechanical devices, etc., can solve the problems of harmonic pollution of power grid, high failure rate assembly conditions, complex structure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

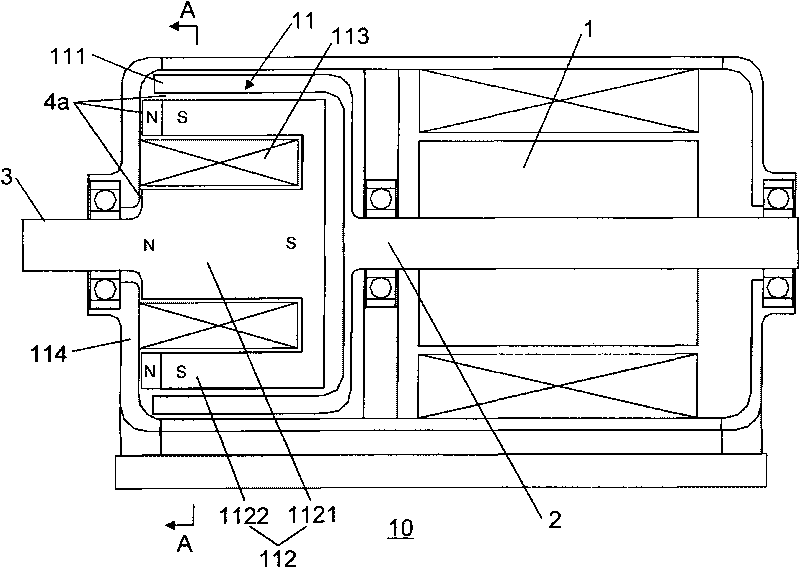

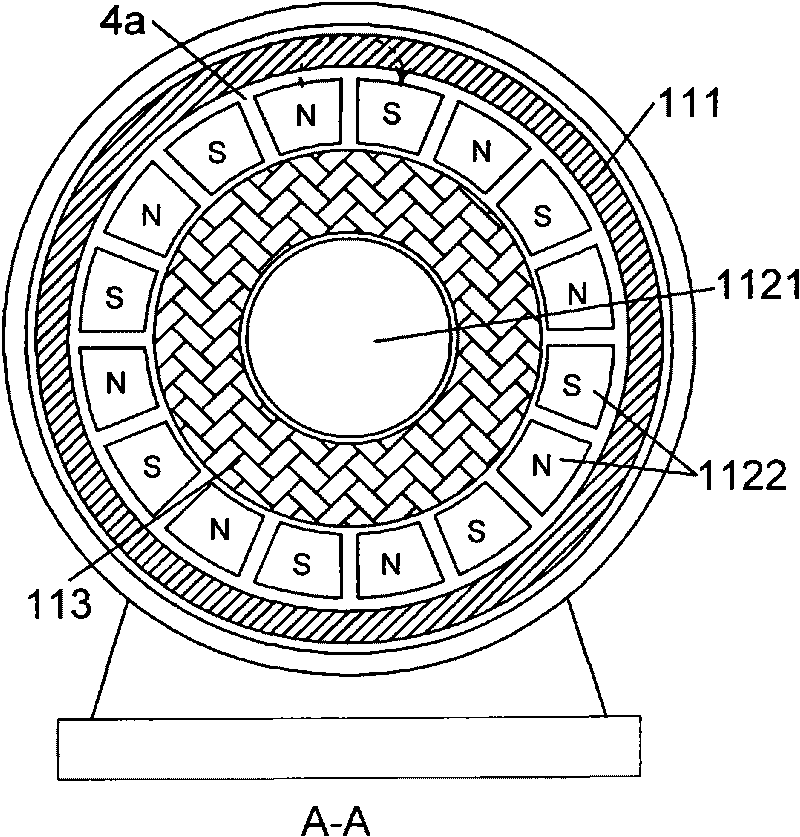

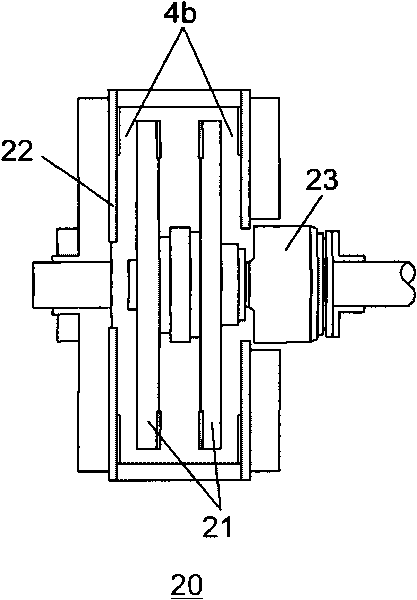

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] see Figure 4 As shown, the electromagnetic coupling excitation governor 30 of the present invention is basically the same as the electromagnetic slip clutch 10 of the prior art, and is also connected between the motor 1 and the load, including a casing 31 and an external rotating shaft arranged in the casing 31. The body 32 , the inner rotating body 33 arranged in the outer rotating body 32 , and the field winding 34 wound on the inner rotating body 33 . Please combine Figure 5 ~ Figure 7 As shown, the difference is that the external rotating body 32 has a cylindrical structure as a whole, and is formed by stacking silicon steel sheets. One end of the external rotating body 32 is connected to the output shaft 2 of the motor 1, and the inner rotating body 32 A plurality of guide bar grooves 321 are evenly formed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com