fluid ejection device

A fluid injection and nozzle technology, applied in fuel injection devices, low-pressure fuel injection, fuel injection devices with piezoelectric elements or magnetostrictive elements, etc., can solve the advantages of valve element opening disorder, fuel flow difficult to control, and resonance Loss and other problems, to achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

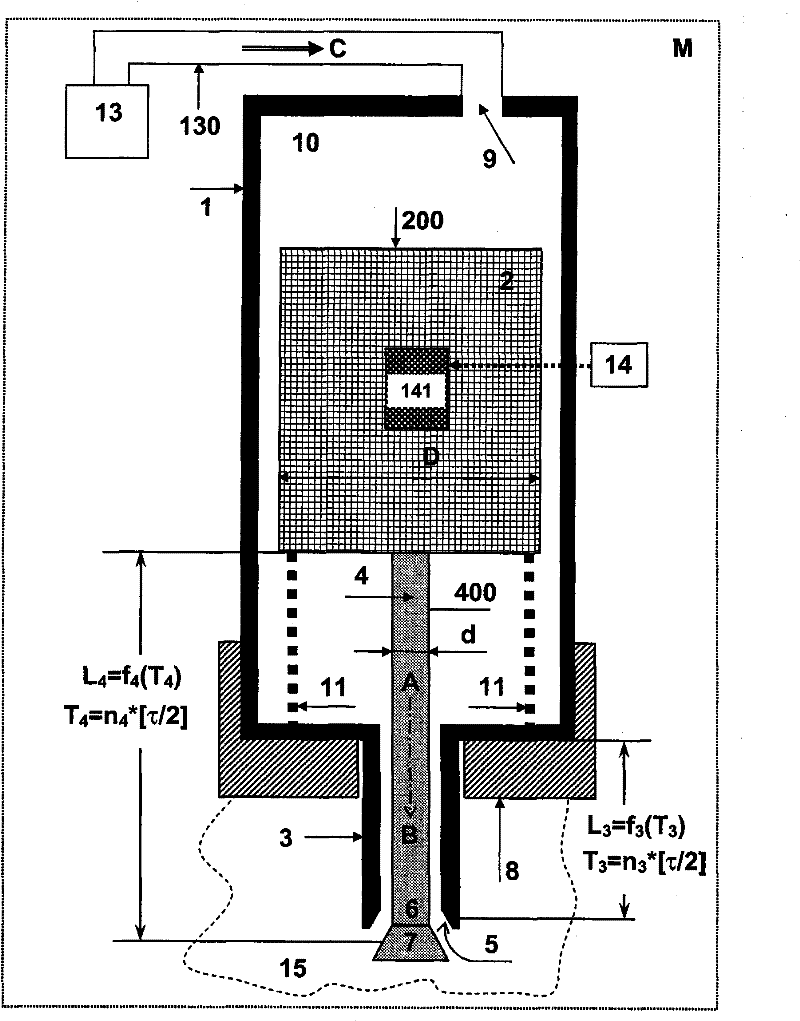

[0032] figure 1 , 3 The injection device or injector of (or 2, 4) is designed to inject fluid such as fuel C into the combustion chamber 15 of the internal combustion engine M or into an intake duct not shown.

[0033]The injector comprises two bodies, for example cylindrical. A first body 1 representing the housing extends on a preferred axis AB of the spray device, for example its axis of symmetry, through at least one nozzle 3 having a length on this axis AB and comprising a spray hole and a seat 5 ( or 5'). The linear dimensions of the first body 1 , such as its width measured perpendicular to the axis AB and / or its length measured along the axis AB, may be greater than the dimensions of the nozzle 3 . The density of the first body 1 may be greater than the density of the nozzle 3 . The first body 1 can be connected to at least one circuit 130 of fuel C via at least one opening 9 . The circuit 130 of fuel C comprises means 13 for treating the fuel C, comprising for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com