Programmable logic controller protocol converter

A programming logic and controller technology, applied in the direction of program control, program control, electrical program control, etc. in sequence/logic controllers, can solve problems such as factory shutdown, easy failure, and a large number of communication cards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

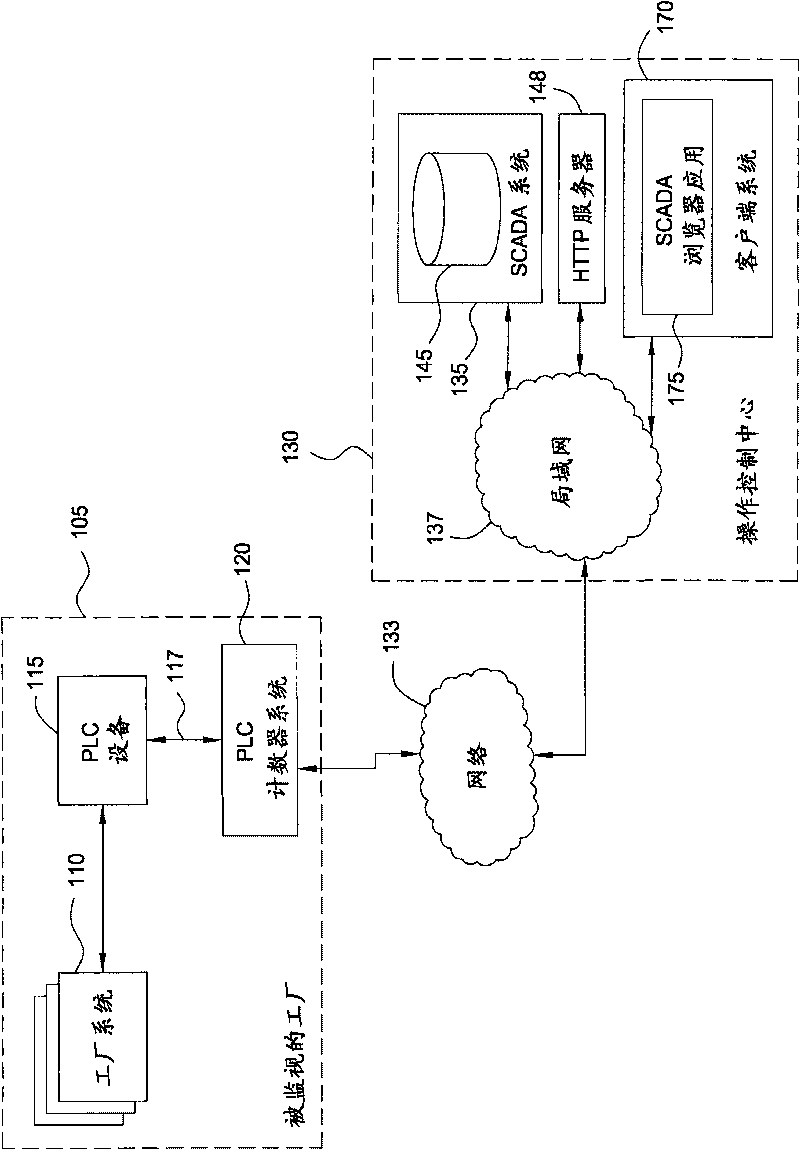

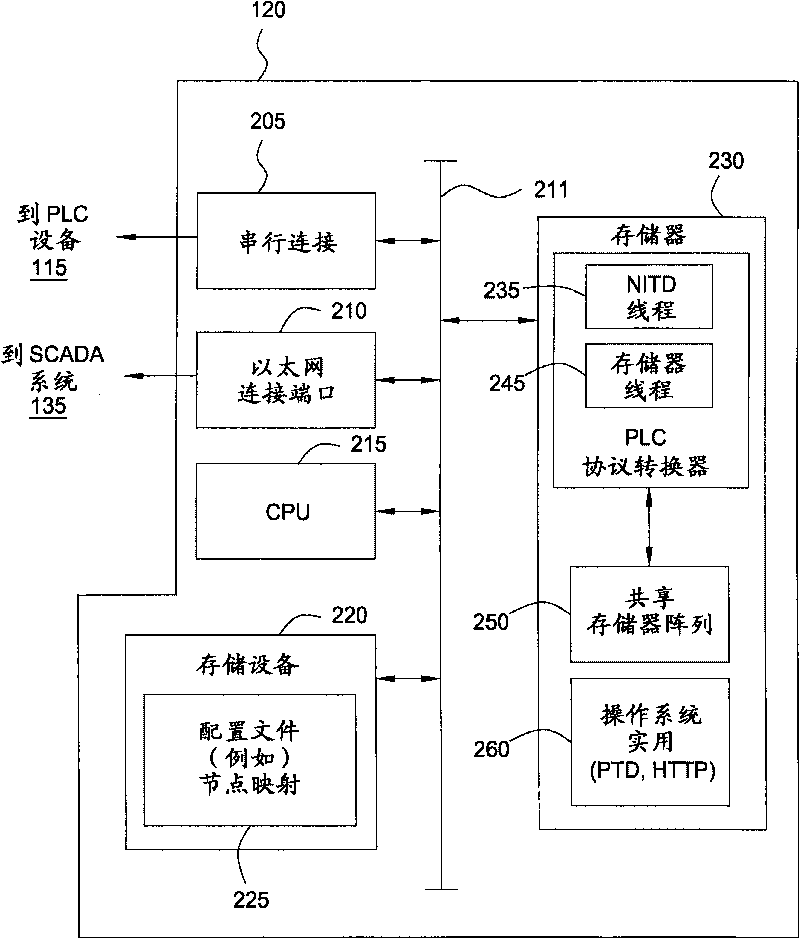

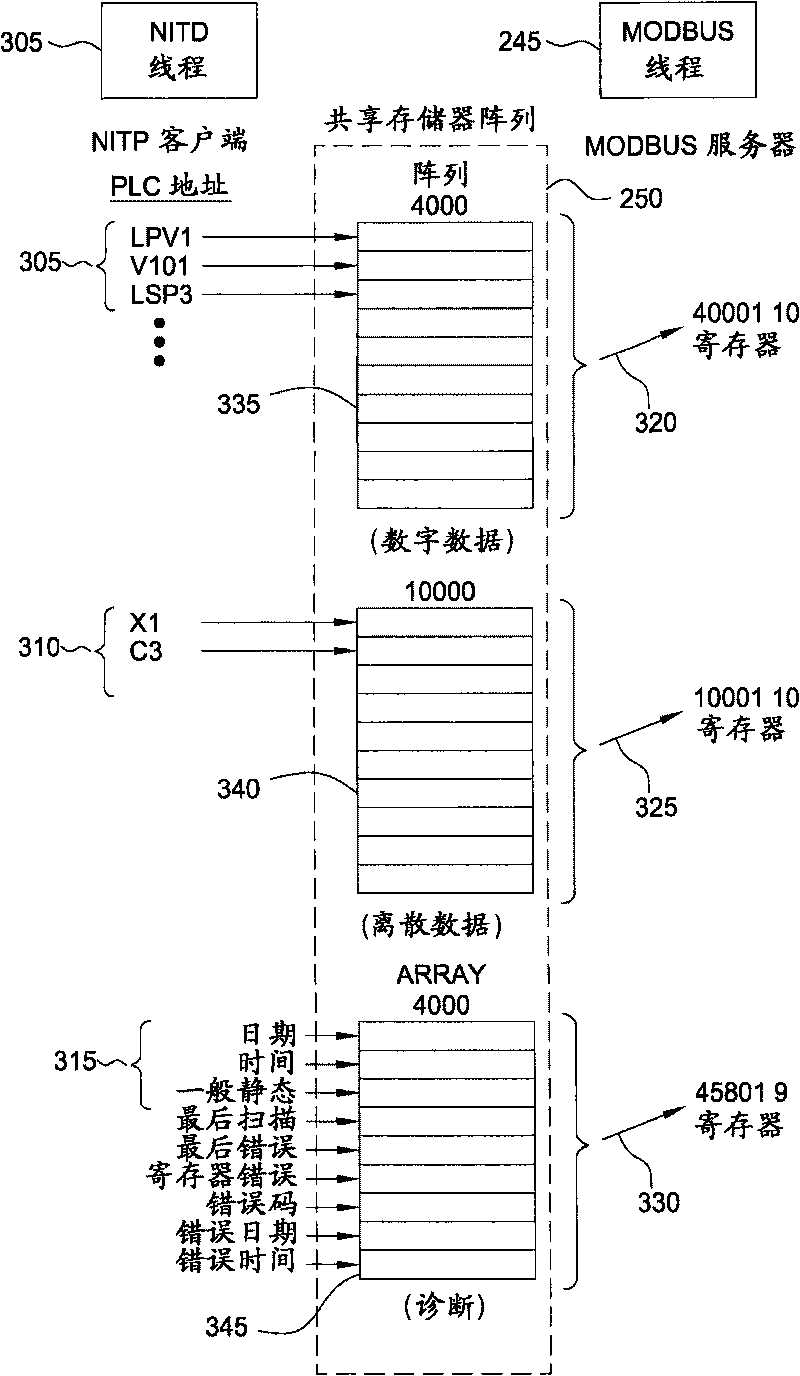

[0013] Embodiments of the present invention provide a PLC protocol converter system that allows a SCADA system to efficiently communicate with a PLC device using a desired communication protocol, especially if the PLC device does not "speak" the desired communication protocol. SCADA systems (short for Supervisory Control and Data Acquisition System) centralize processing data and allow remote monitoring and control of various industrial systems. SCADA systems can be configured to collect data in real-time from remote locations to control equipment and conditions in a pipeline (eg, a hydrocarbon pipeline, or a hydrogen pipeline). For example, a SCADA system may be configured to send a request to a PLC controller for a value recorded at an address in memory representing the then current value of a sensor in an industrial plant, or a discrete state of a component in an industrial plant. For a SCADA system to communicate with a PLC, the two must be able to communicate using compat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap